Ever stricter emission regulations and diverse propulsion types ranging from traditional ICE to full battery electric vehicles are leading to a much higher workload on vehicle test environments. Regulation agencies are asking for full transparency on how a vehicle was certified, including the full chain of custody documentation. First time right for regulation compliant vehicle testing is the key to success.

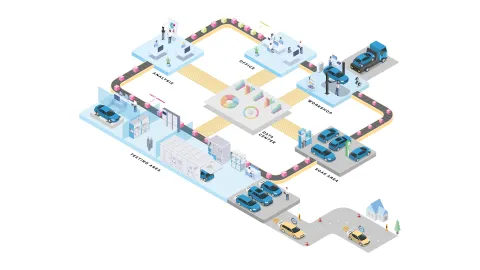

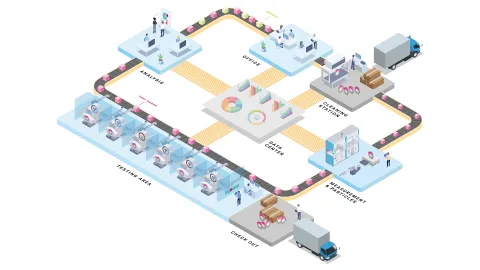

To tackle these challenges and to achieve more with existing testing capacity, your testing infrastructure needs to be optimized for maximum efficiency and productivity. Lab Management for Vehicle is designed with these challenges in mind and addresses them with a modular approach. With a selection of automation modules customizable to your specific needs, it covers everything from R&D to full vehicle certification testing.

Optimal Use of Test Center Capacity

Achieve higher productivity by automating no-value-added tasks and an improved test field planning.

Guided and Monitored Workflows

Guiding operators and securing the traceability of all steps of the process and documentation ensures compliance of your test field.

First time right

Follow the right workflow and avoid manual data copying to improve the quality of your data.

Energy Monitoring

Avoid unnecessary investments and decrease your operational costs for an optimized total cost of ownership.

Our solution was developed together with regulatory agencies and manufactures and is in productive use in their facilities. Deep domain know-how in automotive testing and instrumentation is reflected in AVL’s tailored solutions that fully automate and document testing processes.

Dedicated Process Control Modules ensure an efficient utilization of all laboratory resources. They help stay on top of your test labs quality control processes and significantly reduce administrative efforts in all areas of the test lab.

- Achieve first time right results

- Ensure safe and compliant testing processes

- Use pre-defined or model individual workflows with the open architecture

- Significantly reduce planning and project setup time

The solution allows to fully digitize your individual testing processes and guides every team member in their work.

PROCESS SAFETY

The guided testing approach with regulatory workflow templates reduces human error to a minimum.

PRODUCTIVITY

The high automation level ensures an efficient use of all laboratory resources and reduces planning and project setup time.

MODULARITY

Choose from individual modules to a holistic end-to-end testing solution that is tailored for your needs.

Process Control

The process control module allows you to create individual projects for your test field. All active projects are visible centrally allowing you to monitor their individual progress.

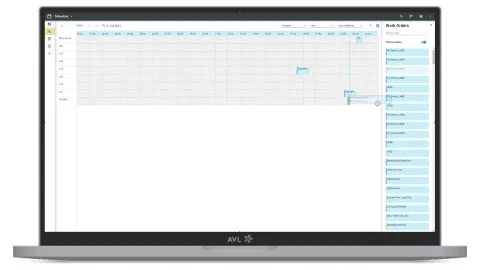

Scheduling

The Scheduling module allows you to manage and monitor individual work orders on all stations in your test field (e.g., a testbed or equipment). The capacity overview supports in planning and utilizing the test field as productive as possible.

Monitoring

Multiple dashboards to monitor all testing processes are available in the monitoring module. They provide an overview over the status of the testing process and gather actionable insights for all teams involved.

Data Management

The solution provides harmonized data integration – independent from the data source. A fully automated, standardized, and scalable data integration provides the foundation for further analysis.

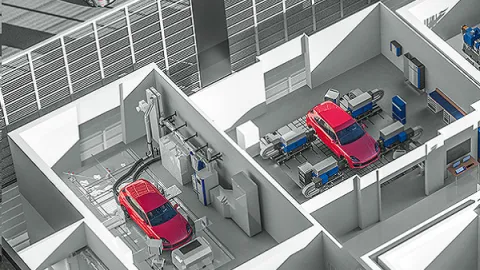

Brake Testing Workflow Support

Our powerful Lab Management Software Solution now also supports the full Brake Emission Testing workflow. This includes seamless integration of test data acquisition, analysis, and reporting, ensuring compliance with the latest regulatory standards. With automated scheduling and real-time monitoring, labs can now streamline operations and enhance testing accuracy like never before.