Even with appropriately sized facilities, effectively managing energy consumption and avoiding power peaks can greatly influence test center operating costs. Comprehensive monitoring of energy usage, coupled with proactive test scheduling, plays a crucial role in optimizing overall energy demand, lowering associated CO₂ output, and minimizing total cost of ownership.

By efficiently utilizing the facility’s power distribution network, organizations can ensure reliable power availability for new applications or future expansions. This strategic approach helps maintain operational efficiency and supports long-term, future-ready growth, ultimately enhancing cost-effectiveness and responsible resource management.

Power Limitations

Facilities are limited in power. Upgrades to test cells are sometimes compromised.

Regeneration Peaks

Some facilities are not allowed to regenerate power to the grid, have limited capabilities, or do not receive compensation.

Planning for New Infrastructure

Planning for a new test cell or building requires an understanding of the power consumption.

High Energy Costs

Controlling where energy is spent is crucial for improving efficiency as energy costs continue to rise.

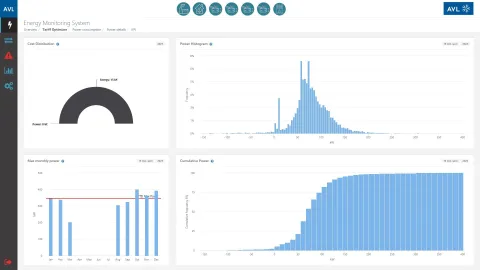

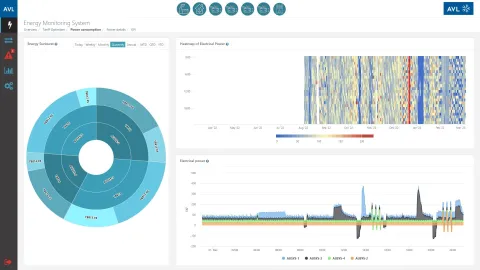

AVL EMOS™ provides real-time monitoring of energy consumption, mapping it directly to corresponding test cycles and linking operating costs to energy use. This advanced tool helps users optimize power costs by analyzing consumed power against the contracted maximum power, supporting effective energy management.

The AVL EMOS™ Management feature increases test center efficiency by optimizing test sequences across multiple testbeds. It supports offline pre-planning, online load control, and prioritization of test cells. Additionally, AVL EMOS™ can operate in bypass mode when load management needs to be temporarily disabled, ensuring flexible control of energy usage and stable operation at all times.

AVL EMOS™ can provide support in three main areas:

Energy Consumption

Reduction

By monitoring energy consumption in connection with various operating parameters of the testbed, it is possible to detect inefficiencies and identify their causes.

Peak Power

Reduction

Efficient synchronization of tests can prevent power peaks. In this way, the power infrastructure and power tariff can be optimized.

Operation Within

Facility Limits

AVL EMOS™ Management ensures that plant limits are not exceeded during operation, avoiding unexpected shutdowns that cause downtime and operational inefficiencies.

Monitoring

AVL EMOS™ enables the allocation of expenses to the correct cost center, defining KPIs for test results, calculating energy and operating costs, and providing important information for new investments in the tech center.

Load Management

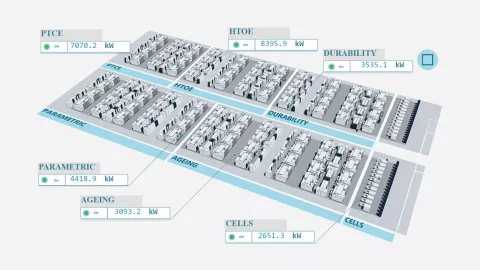

AVL EMOS™ Management dynamically controls and adapts the number of tests running in parallel to avoid exceeding the overall power consumption limit.

Load Simulation

Based on the planned tests, a forecast of the expected power load is calculated, and the user can assess the viability of the proposed test schedule.

Flexibility for a Complete Overview

AVL EMOS™ visualizations, reports and interfaces are flexible and highly configurable. The software can act as a data source for existing BI tools, providing an integrated energy view into your existing data infrastructure.

AVL EMOS™ empowers test fields with a scalable and modular energy management solution. It enables informed decision-making, facilitates regulatory compliance, streamlines buildings permitting processes and reduces the power requirements from utility providers.”

– Miguel Ochoa, AVL EMOS Head of Development, AVL , AVL Iberica S.A.

AVL Tech Center Solutions – Brochure

From Requirements to Reality.

AVL Energy Management Solutions – Whitepaper

Highly Efficient Energy Management for Test Facilities.

AVL EMOS™ – Solution Sheet

Highly Efficient Energy Management.