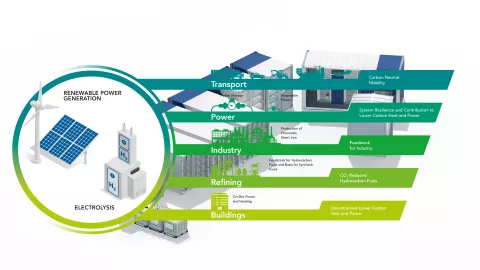

The importance of hydrogen has undergone rapid change. From pure industrial gas, it has advanced to become an energy source for a wide range of applications. To make hydrogen available in large quantities, we have been working intensively on electrolysis processes and procedures for many years.

Up to now, what is known as the low-temperature process has been used primarily. With high-temperature electrolysis, we have embarked on a new technological journey that has made us the technology leader and is revolutionizing the entire field of hydrogen production. We are continuing to invest in this future technology, making us a global premium partner for electrolyzers.

Whatever application you are pursuing to obtain sustainably produced hydrogen: With our intensive activities within the scope of our own research and development, as well as our experience from numerous customer projects, we address the complexity of the topic. This enables us to respond to your specific needs with precision. Which benefits you.

With our comprehensive knowledge, we are there for you throughout the entire technology process.

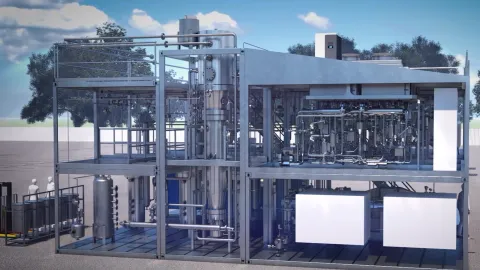

We are currently gaining long-term experience so as to optimize the stability of the systems. In comprehensive detailed engineering processes, we are now developing modular, scalable solutions that we can use specifically for your needs. We work with you to create extremely efficient systems that are flexible and user-friendly.

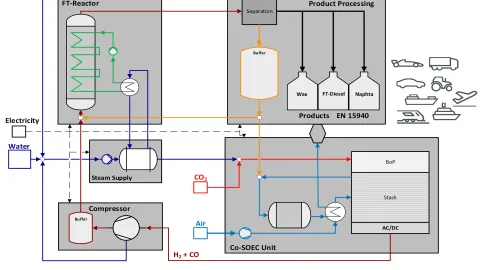

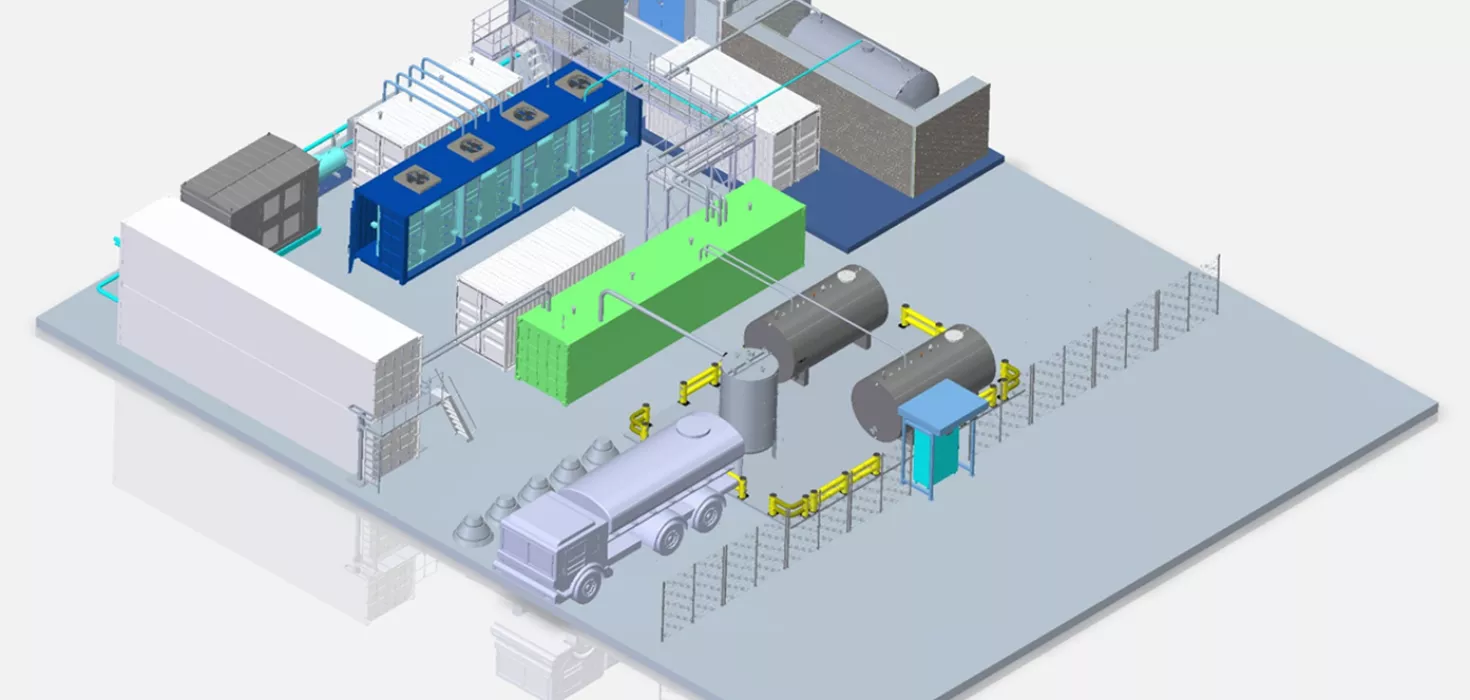

As a comprehensive service provider, we are happy to do pioneering work for you in the technology field of hydrogen production. First, we design a suitable architecture for a future system and take your requests fully into account in this early phase already. A particular challenge in the entire process is the optimal process design. Here we answer the question of which system design concept, which chains of suppliers, which software, and which operating strategy for the system lead to the desired result.

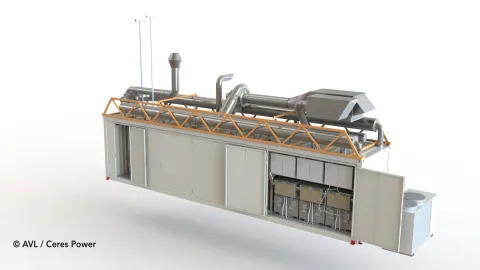

Finally, we design the systems in such a way that they can be integrated into containers reliably later on.

We offer you solutions for parts of a system as well as for complete systems.

The systems drawn up and tested by us to produce climate-neutral hydrogen are designed such that they comply with the various legal requirements and can be brought to the market.

To guarantee you operational reliability in European and non-European markets, we subject our systems to application-specific tests and validation procedures. You can always operate our solutions independently and reliably, and thus establish your desired production capacities for hydrogen on site.

When it comes to electrolysis systems, we guide and support you through all process phases – from consulting to concept development, testing, and implementation.

- For economical production and storage of renewable fuels, our systems with the highest levels of efficiency provide a decisive advantage for you.

- As an independent systems developer, we select the optimal components for you, notably the electrolysis stack. Thereby, we are completely independent of suppliers.

- We consider the downstream processes for the production of synthetic fuels already during the development of the electrolysis systems and integrate these processes into an optimal overall concept.

- Are you an established power generation company – or more of a technology start-up? Whatever the case, our well-founded expertise and state-of-the-art test infrastructure make us your ideal point of contact.

News

Moving steadily into the future: Find out what’s brand new in the field of electrolysis systems engineering.