AVL CELL TESTER™ Performance

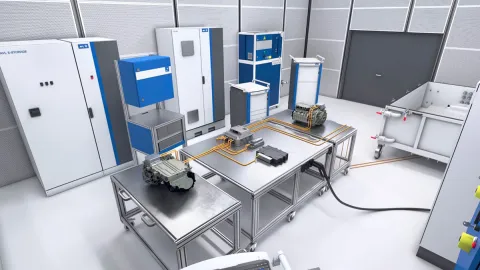

The Performance Line cell cyclers are tailored for high-performance testing scenarios, such as investigations into fast charge profiles and early-stage high-quality testing for large capacity battery cells. It is ideal for applications requiring test profiles with integrated EIS measurements, enabling high-precision coulometry (HPC) cycles. With its super-compact power electronics and advanced features, the Performance Line provides customers with greater flexibility in their testing use cases.

| Current Options | 300 A, 600 A |

| Voltage Range | –0.1 to 6 V |

| Current Measurement Method | measured value based accuracy |

| Current Accuracy | ±0.01 % (measured value) ±2.5 mA (full scale offset) |

| Voltage Accuracy | <± 0.9 mV (0.01% FS) |

| Rise Time | up to 0.5 ms |

| Cooling | water cooled |

| Efficiency | up to 88 % |

| Integrated EIS | yes |

AVL CELL TESTER™ ECO

The ECO Line cell cyclers are designed for testing scenarios where ultra-high performance is not necessary. These cyclers offer reliable and efficient performance, making them ideal for applications such as life cycling and other routine tests. The ECO Line provides a practical solution for standard testing needs, ensuring dependable results without the need for advanced features. Together, these two product lines ensure that we can meet a wide range of testing requirements.

| Current Options | 12 A to 600 A |

| Voltage Range | 0.5 to 5 V |

| Current Measurement Method | full scale on range |

| Current Accuracy | ± 0.02 % |

| Voltage Accuracy | <± 1 mV (0.02% FS) |

| Rise Time | up to 5ms |

| Cooling | air cooled |

| Efficiency | up to 75 % |

| Integrated EIS | no |

At AVL, we believe that a mix of both our Performance Line and Eco Line cell cyclers will help you reduce costs while still covering a wide variety of testing scenarios. Both product lines are backed by comprehensive sales, service, software, and application support. This ensures that regardless of the product line you choose, you benefit from consistent, high-quality support, allowing you to focus on your core business of testing with ease and confidence.

Highest Regenerative Efficiency

With high regenerative efficiency, both internally and externally, and the power grid, it guarantees your operating costs remain low.

Requires Minimum Space

With its ultra-small footprint, it is easy to accommodate our Cell Tester in an increasingly crowded lab.

Fastest Results

Thanks to its optimized functionalities, you are able to control a high number of channels and a large number of devices, all in real time.

Advanced Energy Management

Thanks to the latest SiC technology, the Cell Tester has 95 % bi-directional efficiency.

At AVL, we understand the diverse needs of battery cell testing across various applications. With our products, we offer tailored solutions that ensure high-quality results.

– Stefan Fingerlos, Group Product Manager

AVL Cell Testing Solutions – Brochure

Master the heartbeat of the battery. From single channel to automized lab testing.

AVL E-Mobility Testing Solutions – Brochure

From battery to full vehicle, from products, to test systems to whole test facilites – learn how we can support your testing needs.

AVL CELL TESTER™ Performance – Solution Sheet

Up to 12 high-performance cell testing channels.

AVL CELL TESTER™ Performance – Data Sheet

For demanding cell testing applications.

AVL CELL TESTER™ ECO – Solution Sheet

Indispensable in high-channel battery cell testing.

AVL CELL TESTER™ ECO – Data Sheet

Air-cooled, multi-channel battery cell test system.