powertrain engineering

A U G U S T 2 0 1 8 1 3

LOW SYSTEM COSTS WITH COMPONENT

KNOW-HOW

Profound knowledge at component and system level as well as in terms

of development and production is indispensable. It will be vital to meet

the increased demand for BEVs (battery electric vehicles) in the future,

and to offer electric vehicles with greater range, performance and faster

charging processes.

“In the last five years, the world view of electrification has completely

changed. Back then everybody thought that components from passenger

cars could simply be shared with the commercial vehicle sector and combined

into one drive to keep costs low,” explains Walter. “After the first attempts,

however, people quickly realized that this approach was not feasible.

To guarantee the best vehicle performance at the best product costs, we need

components that are developed, or at least adapted, for use in the commercial

vehicle sector.” With battery-powered commercial vehicles in particular,

development and product costs are a decisive issue due to the low number

of units manufactured. Therefore, AVL develops specific battery systems

for trucks and buses with the focus on keeping system costs low without

sacrificing appropriate vehicle performance. The module-based

solutions

create advantages in terms of cost, weight and installation space and make

a significant contribution to responding flexibly to market requirements.

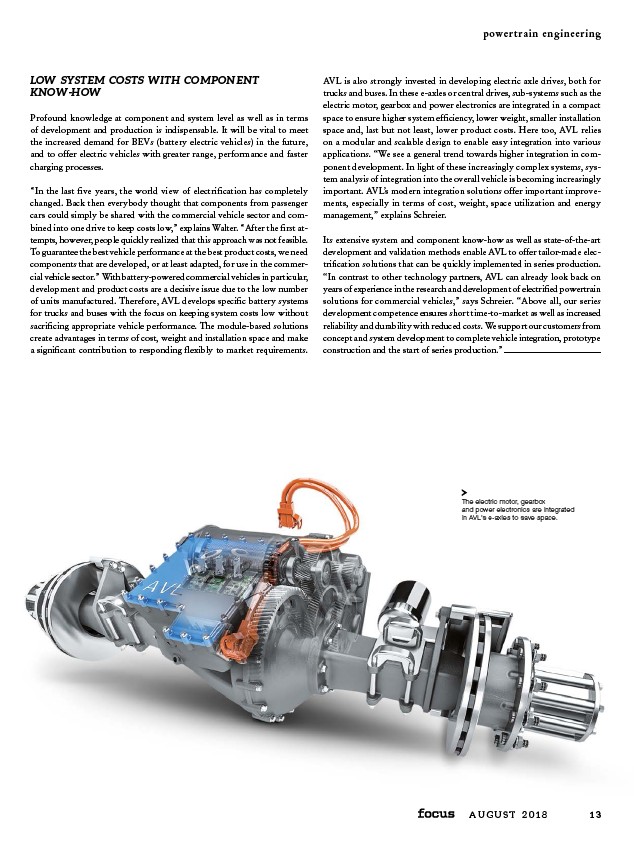

AVL is also strongly invested in developing electric axle drives, both for

trucks and buses. In these e-axles or central drives, sub-systems such as the

electric motor, gearbox and power electronics are integrated in a compact

space to ensure higher system efficiency, lower weight, smaller installation

space and, last but not least, lower product costs. Here too, AVL relies

on a modular and scalable design to enable easy integration into various

applications. “We see a general trend towards higher integration in component

development. In light of these increasingly complex systems, system

analysis of integration into the overall vehicle is becoming increasingly

important. AVL’s modern integration solutions offer important improvements,

especially in terms of cost, weight, space utilization and energy

management,” explains Schreier.

Its extensive system and component know-how as well as state-of-the-art

development and validation methods enable AVL to offer tailor-made electrification

solutions that can be quickly implemented in series production.

“In contrast to other technology partners, AVL can already look back on

years of experience in the research and development of electrified powertrain

solutions for commercial vehicles,” says Schreier. “Above all, our series

development competence ensures short time-to-market as well as increased

reliability and durability with reduced costs. We support our customers from

concept and system development to complete vehicle integration, prototype

construction and the start of series production.”

The electric motor, gearbox

and power electronics are integrated

in AVL's e-axles to save space.