fuel cell

A U G U S T 2 0 1 8 2 5

Some of the biggest obstacles faced

by PEMFC and SOFC are being

tackled with this simulation-based

approach. For light-duty vehicle

applications of PEMFC, one such

challenge is to maximize performance

and the life expectancy of

the fuel cell. For SOFC applications,

challenges include optimized

efficiency and durability at minimal

life cycle cost. To face up to these

kinds of tasks AVL has developed

the AVL FIRE™ modelling tool.

AVL FIRE™ offers dedicated multiphysics

simulation capabilities that

consider the relevant physical and

electrochemical processes of PEMFC

and SOFC operation. From analyzing

PEMFC-related multiphase

flow, thermal and electromechanical

processes, including degradation

on both cell and stack level, to the

complex fluid-dynamic, thermal and

electrochemical processes in SOFC

cell and stack configurations, AVL

FIRE™ is a proven and versatile

tool. It delivers the ability to optimize

flow field design to avoid local

fuel starvation and liquid water accumulation,

which can be damaging

to the cell, and allows the modelling

of cell degradation to therefore maximise

the fuel cell’s lifespan.

In addition to AVL FIRE™ another

valuable tool that is helping

to realize the establishment of fuel

cell technology in the marketplace

is AVL CRUISE™ M. This simulation

tool offers dedicated multiphysics

modelling capabilities that

can aid the optimization of entire

fuel cell systems and their different

parts, such as BoP and coolant

circuit components. Transient

load pick-up response, system efficiency

under real operating conditions

and start-up and shut-down

behaviors can all be modelled in

AVL CRUISE™ M, to set and meet

development targets.

Having access to simulation tools

such as these enables testing to begin

early on in the development

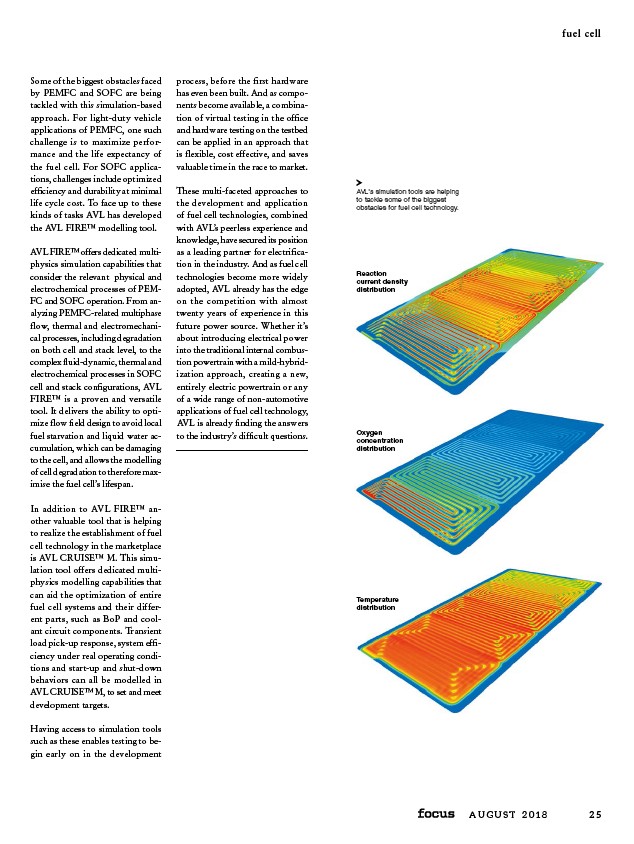

AVL's simulation tools are helping

to tackle some of the biggest

obstacles for fuel cell technology.

Reaction

current density

distribution

Oxygen

concentration

distribution

Temperature

distribution

process, before the first hardware

has even been built. And as components

become available, a combination

of virtual testing in the office

and hardware testing on the testbed

can be applied in an approach that

is flexible, cost effective, and saves

valuable time in the race to market.

These multi-faceted approaches to

the development and application

of fuel cell technologies, combined

with AVL’s peerless experience and

knowledge, have secured its position

as a leading partner for electrification

in the industry. And as fuel cell

technologies become more widely

adopted, AVL already has the edge

on the competition with almost

twenty years of experience in this

future power source. Whether it’s

about introducing electrical power

into the traditional internal combustion

powertrain with a mild-hybridization

approach, creating a new,

entirely electric powertrain or any

of a wide range of non-automotive

applications of fuel cell technology,

AVL is already finding the answers

to the industry’s difficult questions.