cover story

8 A U G U S T 2 0 1 8

‹F.›: At present, the hydrogen for fuel cell drive systems is still mainly

obtained from fossil energy sources such as natural gas. This is not

really ‘green’ yet, is it?

‹Mohrdieck›: Agreed, but this is only a first step to show that local emissionfree

driving with fuel cell technology could be a real alternative. Even with

hydrogen obtained from natural gas, CO2 emissions in the entire chain can

be reduced by a good 25 percent. The important thing is that it can be produced

on a ‘green’ basis. Plenty of approaches have already been developed

to achieve this. Hydrogen is the ideal energy storage medium for wind and

solar power, both of which are not generated continuously. With a steadily

growing share of renewable energy sources, hydrogen will certainly play

an increasingly important part in the overall energy system, and this will

make it more and more attractive for the mobility sector.

‹F.›: And is this where your involvement in stationary fuel cell systems

comes into play?

‹Mohrdieck›: Exactly. The potential of hydrogen beyond the automobile –

e.

g. utility, industrial and domestic solutions – is manifold and requires the

development of new strategies. Economies of scale and modularization are

important factors in this respect. Together with our ‘Lab1886’ innovations

lab and computing experts, we are currently working on the development

of prototype systems for the (emergency) power supply of computer centers

and other stationary applications. For this purpose, we are using the

fuel cell systems of the GLC F-CELL pre-series vehicles.

‹F.›: Where is the fuel cell heading?

When can we expect a breakthrough?

‹Mohrdieck›: We are only at the beginning.

I think that by the middle

of the next decade – but certainly

after 2025 – the relevance of the fuel

cell will increase generally and for

the transport sector significantly.

By this I don’t mean a sudden explosion,

as it will probably only account

for a single-figure percentage

of the global market. But even moderate

volumes will help to create

standards that are especially essential

for cost reduction. We must

not forget that for a technology

to achieve a breakthrough, it must

be attractive for both sides – the

customers and the manufacturer.

‹F.›: What still needs to be done?

What are the next steps?

‹Mohrdieck›: We need industrial

standards to progress to very large

vehicle production volumes. Further

development work is particularly

necessary to reduce material

costs: factors of relevance include

the further reduction of sizes and

components, and also of the proportion

of expensive materials. If we

compare our present system with

that of the B-Class F-CELL, we

have already achieved a great deal –

just by reducing the platinum content

by 90 percent. But we need to

go further. Process optimizations in

production will also help to lower

the costs – but that is more a matter

of economies of scale. Cooperation

in cross-manufacturer projects such

as ‘Autostack Industrie’ and the expected

worldwide investment in the

technology will certainly contribute

to this.

‹F.›: Will the fuel cell also be used

in other vehicle segments as a next

step?

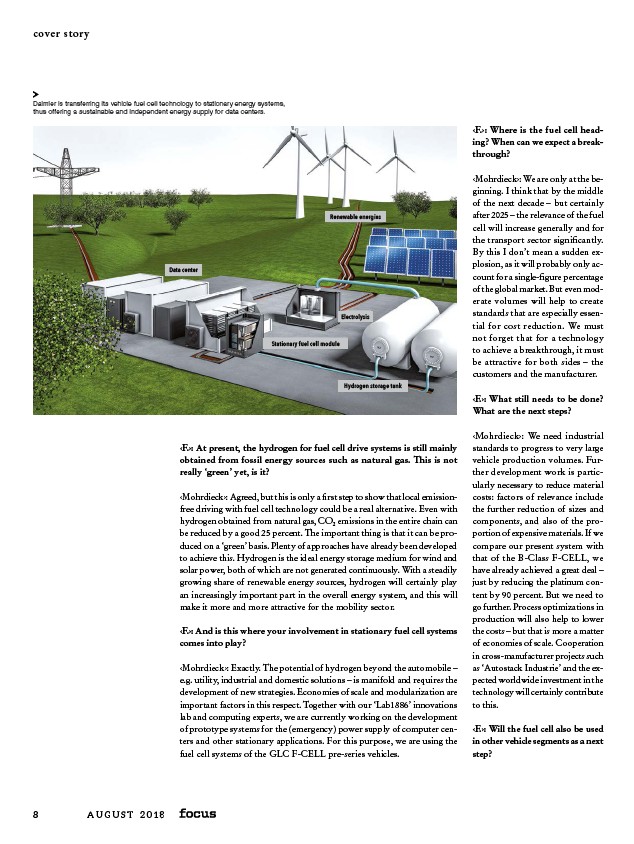

Daimler is transferring its vehicle fuel cell technology to stationary energy systems,

thus offering a sustainable and independent energy supply for data centers.

Renewable energies

Data center

Electrolysis

Hydrogen storage tank

Stationary fuel cell module