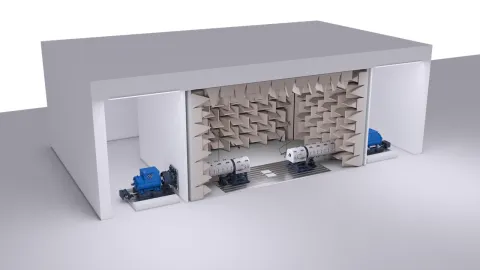

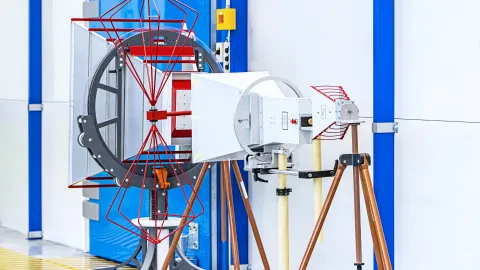

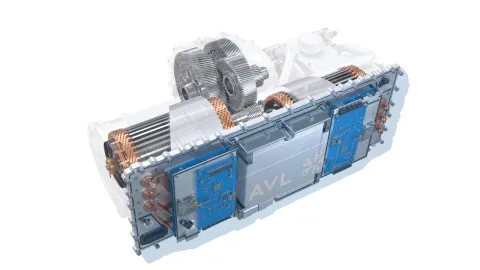

最新のe-アクスルシステムは非常にコンパクトでありながら、最高水準の出力密度で設計されています。また、効率、性能、操縦性の面で最適化されています。e-アクスル試験システムは、耐用期間および性能に関する要件を満たす必要があります。運転時の利便性を確保し、車両安全性を確保するための厳格なEMC規制範囲内にとどまるためには、NVHに関する困難な要件にはさらに対処する必要があります。

社内のエンジニアリング部門では、お客様に最善のアドバイスとサポートを提供するために、市場とイノベーションを綿密に評価し、積極的に形成しています。こうした用途のノウハウに基づいて、お客様が持続的かつ効率的に開発目標を達成できるようなe-アクスル試験システムソリューションを開発しています。」

- AVL Deutschland GmbH システムラインマネージャー Klaus Pfeiffer

TCOの最小化

稼働寿命、NVH、EMC用途向け設計済みソリューション 。設置面積を抑え、稼働時電力を最小化

効率性の向上

あらゆるツールを自動化システムにシームレスに統合し、試験の完全自動化を実現することで、生産性を高めます。

高度な持続可能性

システムは最小限の電力を使用するように構築されています。

AVL E-Mobility Testing Solutions – Brochure

From battery to full vehicle, from products, to test systems to whole test facilites – learn how we can support your testing needs.

AVL E-Axle Testing Solutions – Brochure

Validating Integrated E-Drive Units with Advanced E-Axle Test Systems.

Automation & Control for E-Axle Testing – Solution Sheet

Highly efficient automation and control for e-axle testbeds.

AVL offers comprehensive software solutions to optimize your e-axle testing performance. Our holistic approach combines lab efficiency through automation and test optimization via virtualization for faster results.

The advanced data analytics solution using AI extracts valuable insights from various sources. Additionally, our solutions are designed to seamlessly integrate with your existing systems, ensuring a smooth transition.

This will help you get your products to market faster while ensuring high-quality performance. Learn more about AVL’s approach and explore our software solutions to optimize your e-axle testing process now.

長年の研究・開発、ならびに生産の経験に基づいて、AVL E-Axle TS™ Productionを開発しました。乗用車から高性能車までの電気駆動アプリケーション、および産業アプリケーションのEOL(エンドオブライン)およびCOP(生産適合性)試験を提供しています。

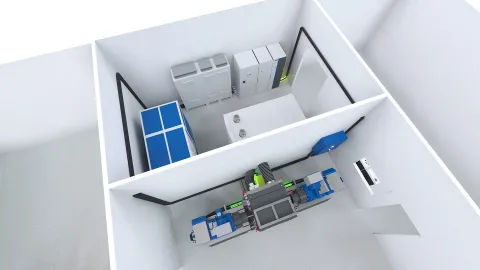

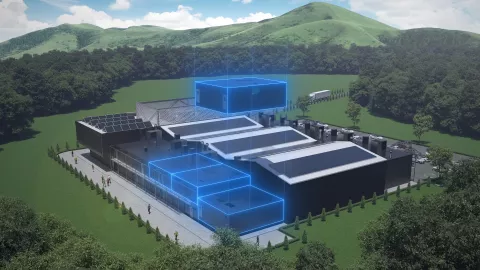

お客様の要件から、高度な製品開発計画に対応するため、追加のテスト容量が必要であることが示されています。AVLテックセンターモジュールは、このプロセスを大幅に短縮します。柔軟で、場所に依存せず、容易に再配置可能なモジュール式テストシステムは、特に有効です。

e-モーター試験向けクラス最高の自動化システムです。

AVLカスタマーサービス部門は、世界中に700人以上のサービスおよびアプリケーションエンジニアを擁し、50以上の拠点から運営されています。私たちのグローバルなネットワークが、あなたの地域での利便性を提供します。

AVLの先進的な自動化システムに最適なハードウェア

インテリジェントな自動化を、迅速かつ簡単に

AVL CAMEO 5™は、自動車ソフトウェア試験におけるキャリブレーションと検証をさらに成熟させています。

AVLの総合グローバル専門家ネットワークにより、お客様にとって最良の周辺環境を提供し、一貫性のある試験フィールドへのアクセスを世界中で提供します。常にお客様に寄り添って、研究開発における課題に対して必要なサービスを提供しています。

> 30

事業経験年数

> 4000

パワートレインのエキスパート

> 500

実施されたパワートレインおよびe-アクスルプロジェクト

> 45

グローバルテクニカルセンターおよびエンジニアリングセンター