Innovative Approach to ADAS/AD Vehicle Validation

- News

Simulation tools have become increasingly popular by OEMs and Tier 1 suppliers to accelerate the ADAS/AD systems development process while minimizing the cost associated with test vehicles. Not only do simulation tools cut overall development and validation cost, but they also mitigate risks that could occur while performing tests with real vehicles and personnel.

AVL extended this approach by going beyond the boundaries of pure simulation. It has created a more efficient vehicle and ADAS system validation method, which combines the real-world and virtual testing. AVL developed the AVL DRIVINGCUBE™ to integrate all vehicle development processes into one turnkey solution, combining simulation models, test environments, devices, data, and automation solutions.

In collaboration with Clemson University, AVL commissioned its first and only DRIVECUBE in the United States at the institution’s International Center for Automotive Research (CU-ICAR) in Greenville, South Carolina. Clemson researchers will leverage the system to demonstrate comprehensive vehicle-in-the-loop (ViL) research, development, and testing across dozens of projects.

Let’s explore what exactly the AVL DRIVINGCUBE is, how this system is set up, and how thought-leaders, like Clemson, are using the solution to advance ADAS/AD research and development for on-road and off-road vehicle autonomy.

What is AVL DRIVINGCUBE?

With a comprehensive suite of sensor stimulation and full-range steering ability, the AVL DRIVINGCUBETM brings the proving ground to a testbed environment by combining simulation and a ready-to-drive vehicle on a chassis dynamometer or powertrain test cell. The overall system consists of tools including a camera, radar, and GNSS stimulators, that integrates the physical unit under test (UUT) and the testbed to a virtual environment.

An over-the-air stimulation or injection method can be used to test the perception algorithms. An over-the-air stimulation provides external sensor stimulation to allow the sensor to sense and identify the object. For example, if a third-party is aiming to validate their ADAS functions for consumer feedback, normally they would not have access to the ADAS controller/ECU. In this case, the external sensor stimulation would be utilized to independently validate the functionality.

On the other hand, the injection method pushes either raw data or an object list into the ADAS controller. Since there is no technology that allows for external stimulation of LiDAR sensors, the injection method can be utilized to test higher level ADAS/AD vehicles that rely on LiDAR to obtain the object list and relevant information. In this case, one can inject the full data to test and validate the overall perception quality or simply inject an object list and information to test the various ADAS/AD features.

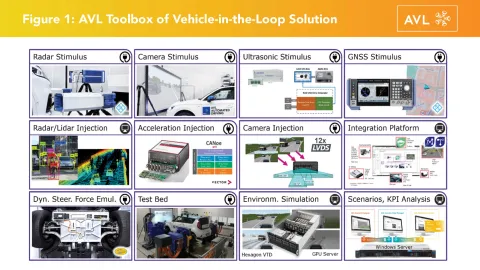

Vehicle-in-the-loop testing solutions aim to enhance and accelerate the validation and approval process of ADAS/AD systems by using fully automated, scenario-based testing, thus increasing test coverage, and reducing testing effort. Figure 1 in the media gallery illustrates the AVL toolbox of vehicle-in-the-loop solutions.

System Integration

CU-ICAR is a noteworthy example of how a standard chassis dyno can be outfitted with the AVL DRIVINGCUBE™ package to interface with the testbed, the UUT, and the simulation environment.

The center’s existing 4x4 chassis dyno connects to the AVL co-simulation platform via CAN communication to transfer the wheel speed and torque information to the virtual environment. A steering force emulator and camera stimulation equipment were physically tied into the virtual environment via CAN communication and an HDMI cable, respectively.

CU-ICAR’s test cell includes AVL’s Dynamic Steering Force module, which emulates lateral steering force while performing tests on functions such as Automated Lane Keeping System (ALKS). Maneuvers to switch lanes, actively stay in lane, and driving around curves can be mimicked on a testbed environment seamlessly, safely, and efficiently.

Additionally, camera stimulation equipment mimics exterior scenarios via a display to test the vehicle’s on-board camera via virtualization software.

All software is in the control room whereas the steering force module is mounted on the vehicle’s steering mechanism, along with the camera projection onto the screen. Figure 2 illustrates the overall block-diagram of the ViL setup at CU-ICAR.

Co-Simulation Platform

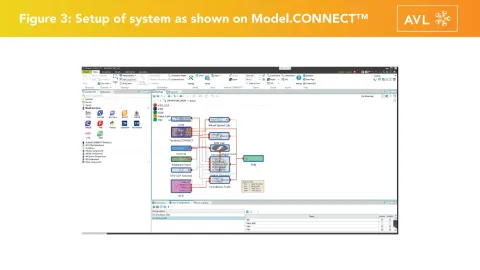

Seamless integration of a virtual environment with a physical unit under test is key to successful co-simulation. In order to combine various sensor stimulation equipment, the ADAS controller, and the virtual environment, AVL utilizes Model.CONNECT™and Testbed.CONNECT™.

Model.CONNECTTM is the core tool that connects to and integrates the DRIVINGCUBETM into the virtual environment. This may include Hexagon VTD for environment simulation (rendering and traffic) and AVL VSM or can be modularly replaced with any other software for vehicle dynamics.

Testbed.CONNECTTM is used to link Model.CONNECTTM with the testbed controller (which, for CU-ICAR, is the RENK chassis automation system). Note that Model.CONNECTTM is flexible and can also deploy and execute fully in a virtual environment without the need for the DRIVINGCUBETM and/or all its sensor/stimulation components. To view the system setup, please refer to Figure 3.

Clemson University

One of the most productive public research universities in the nation, Clemson University enrolls 27,341 students across the State of South Carolina and has an endowment of over $1 billion. Classified as an R1 — Very High Research University by the Carnegie Foundation for the Advancement of Teaching — Clemson is dedicated to teaching, research, and service.

Early Clemson University projects using the AVL DRIVECUBE include vehicle-in-the-loop testing related to the University's Virtual Prototyping of autonomy-enabled Grounds Systems (VIPR-GS) Center and Clemson’s Open Connected and Automated Vehicle (OpenCAV) lab.

Run from Clemson's dedicated automotive research center CU-ICAR in South Carolina, VIPR-GS and OpenCAV leverage the University's deep research expertise and interdisciplinary culture to deliver dual-purpose breakthrough innovation.

Figure 4 features the current setup with OpenCAV Autonomous Pacifica at CU-ICAR Chassis Dynamometer Lab.

Summary

By integrating the AVL DRIVINGCUBETM into Clemson’s existing infrastructure, research teams now have expanded test cell capabilities. Clemson researchers can validate the autonomous functions they develop on a testbed environment, which allows for safe and systematic testing, minimizing the need for track time which can be expensive.

The key benefits of using a real vehicle in a virtual environment are that no control model is needed, tests are highly reproducible, and AVL’s tools are open to third-party models and hardware offering flexibility. This particularly innovative method in testing ADAS/AD features on vehicle have proven to optimize reliability, which can be witnessed at the CU-ICAR facility.

To stay up to date on the latest news between Clemson and AVL, please visit: https://bit.ly/3OuWBIR.