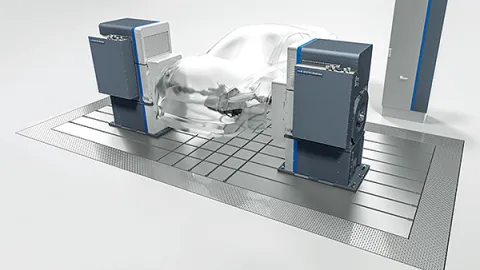

Our testbeds have been at the forefront of electromobility and the automotive industry for over seven decades. Our state-of-the-art dynamometers set industry standards with power ranges from 10 kW to 140,000 kW. This extensive range has revolutionised the development of propulsion systems, serving applications from small off-road engines to large two-stroke marine engines.

Today, we continue to lead the field in e-mobility, pushing the boundaries of technology and actively shaping the future of sustainable transport. Our dynamometers are integral to the testing and optimisation of electrified powertrains and their key components. They are a vital link between our proven expertise and a sustainable electrified future.

Designed for research, development, calibration and certification, our dynamometers demonstrate our commitment to driving innovation in electromobility while embracing a wide range of powertrain technologies across all mobility sectors.

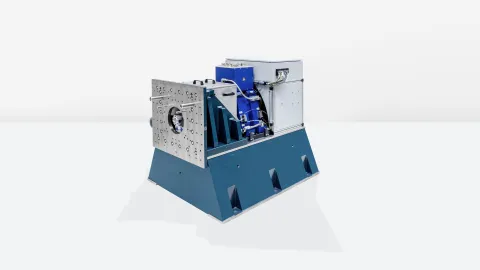

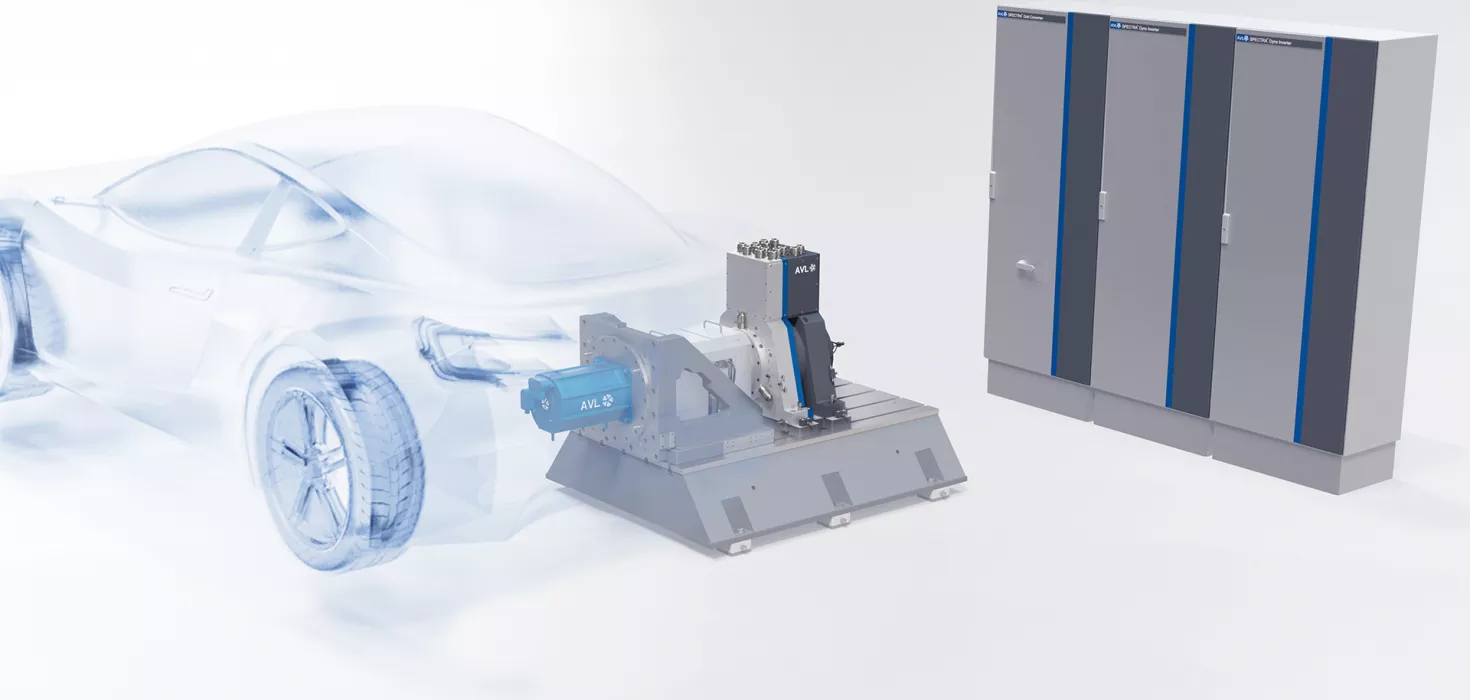

The quintessence of more than 75 years of design and test experience in a single product line. With AVL SPECTRA™, we offer you a product line that covers every conceivable application in automotive testing and is always at the cutting edge of technology. The heart of our Signature Line, the AVL SPECTRA™ SmartStack, is a technological masterpiece. With full SiC MosFET technology for fast switching up to 100 kHz and six parallel half bridges for flexible applications, it is the foundation for future-proof solutions. The brain of our systems, the AVL SPECTRA™ Control Unit, is a state-of-the-art FPGA-based control unit with a cycle time of 1 MHz. It offers real-time EtherCAT interfaces and a variety of integrated monitoring inputs for maximum precision and control.

The bones, our AVL SPECTRA™ modules, are equipped with advanced passive components and are ready for a wide range of applications. Their modular design ensures future-proofing and compactness. Reach new dimensions with the AVL Performance Line: Dynos up to 1800 kW, speeds up to 30,000 rpm and torques up to 32,000 Nm. From single machine test benches to all-wheel drive test benches including single drive machines, we offer solutions that cover a wide range of UUTs (Unit Under Test) and applications, including all drive types such as electric motors, combustion engines and more.

Our AVL dynamometers are built on seven decades of expertise from our global network of experts. Compact, rugged, and easy to service, we have delivered thousands of installations worldwide. Our simulation expertise supports a complete mechanical setup that fits into your existing architecture with minimal disruption. And our global support network ensures that we are there when you need us.

AVL SIGNATURE Line – Brochure

Superior Technology – with AVL SPECTRA™ Inside.

AVL E-Mobility Testing Solutions – Brochure

From battery to full vehicle, from products, to test systems to whole test facilites – learn how we can support your testing needs.

AVL SPECTRA™ Universal Inverter – Solution Sheet

Versatile testing device for future-proof e-motor and inverter development.

AVL SPECTRA™ E-Motor Dyno – Solution Sheet

Our load systems offer a range of benefits, which include:

- An energy recovery system that saves energy costs in the testing field.

- Rotor Flux Vector Control Technology to ensure a high dynamic and accurate operation.

- Interfaces according to common standards in the automotive industry.

- State of the art highly reliable safety functions.

- Common DC bus solutions.

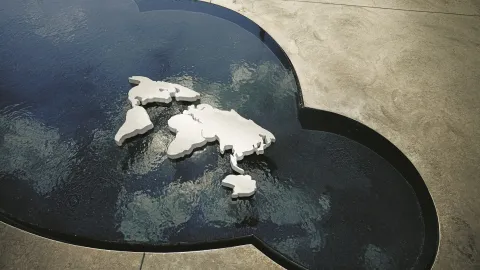

AVL’s comprehensive worldwide network of experts allows best customer vicinity, ensuring consistent and connecting testing fields globally. Wherever your R&D challenges take you, we are always close at hand, ready to provide the service you need.

> 70

years of experience.

> 5000

employees worldwide for testing solutions.

> 30

countries covered by the global network.

> 7000

testbeds installed wordwide.

> 80

turnkey projects realized.

Highlights