The increasing complexity in combustion engines necessitates the implementation of consistent and intelligent test methodologies to ensure optimal performance and reliability. Additionally, test technology must take into account the intricate manufacturing and assembly processes associated with modern engine technologies.

A dependable supplier plays a crucial role in the design phase, offering valuable insights and support to address future challenges. Maintaining the highest level of system quality is essential to prevent costly recalls and protect the brand's reputation. Continuous collaboration between manufacturers and suppliers is key to adapting to evolving demands.

Consistent and Intelligent Test Methodologies

Increasing complexity in ICEs requires implementation of consistent and intelligent test methodologies to ensure optimal performance.

Consideration of Manufacturing and Assembly Processes

Test technology must account for the intricate manufacturing and assembly processes associated with modern engines.

Role of a Dependable Supplier

Choice of supplier is crucial, while providing valuable insights and support to address future challenges and maintain highest level of system quality to prevent costly recalls.

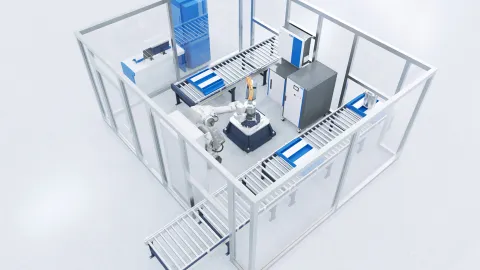

The holistic AVL quality assurance concept considers assembly and production boundary conditions, and delivers a complete system solution for ensuring best-in-class engine and process quality verification. This includes a complete set of testing technology platforms for process and test automation.

It includes in-process verification during engine assembly, functional test after assembly (EOL cold test) and performance tests after assembly (EOL hot test, quality audit / conformity of production test). The solution portfolio for gasoline, diesel, and compressed natural gas (CNG) engines is branded by AVL Engine TS™ EOL Hot and includes:

- EOL Hot: End-of-line loaded hot test systems

- QA/COP: Quality audit / conformity of production test systems

- Qualified Hot: Hot test systems for EOL HOT and QA/COP test

The test systems involve AVL and third-party products and services (e.g. in-house/in-cell integration, enclosures, or complete containerized solutions). Our on-time guaranteed testing capacity ensures strict adherence to standard operating procedures (SOP). With robust hardware and software, we maximize system availability, ensuring that our operations run smoothly and efficiently.

Our flexible and integratable test systems safeguard a 100% stable production process, providing reliability and consistency. Additionally, our accurate, best-in-class test data at the R&D level instills the highest confidence in our test results.

Concept

The AVL solutions ensure efficiency gain through optimized, customized concepts for advanced throughput and product quality.

Implementation

The fast and accurate implementation of AVL hot test systems guarantees an optimal Start of Production (SOP).

Operation

100 % testing throughput and reliable engine verification. Flexible adaptations to changes and preventive maintenance safeguard investment.

At AVL, we see our production testing solutions as an important factor for both an effective production process and high product quality – a major pillar our customers can rely on.”

– Robert Nemeth, Department Manager, AVL List GmbH