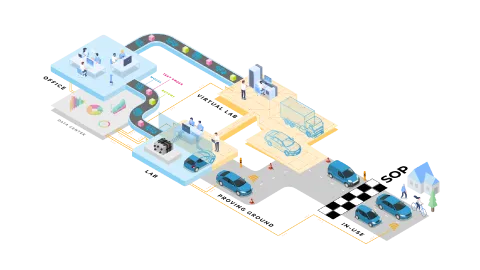

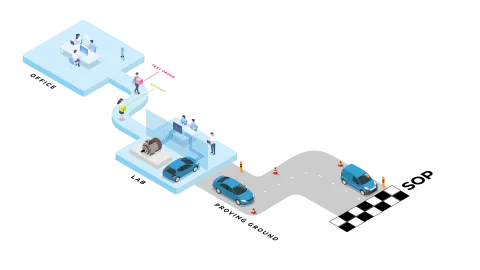

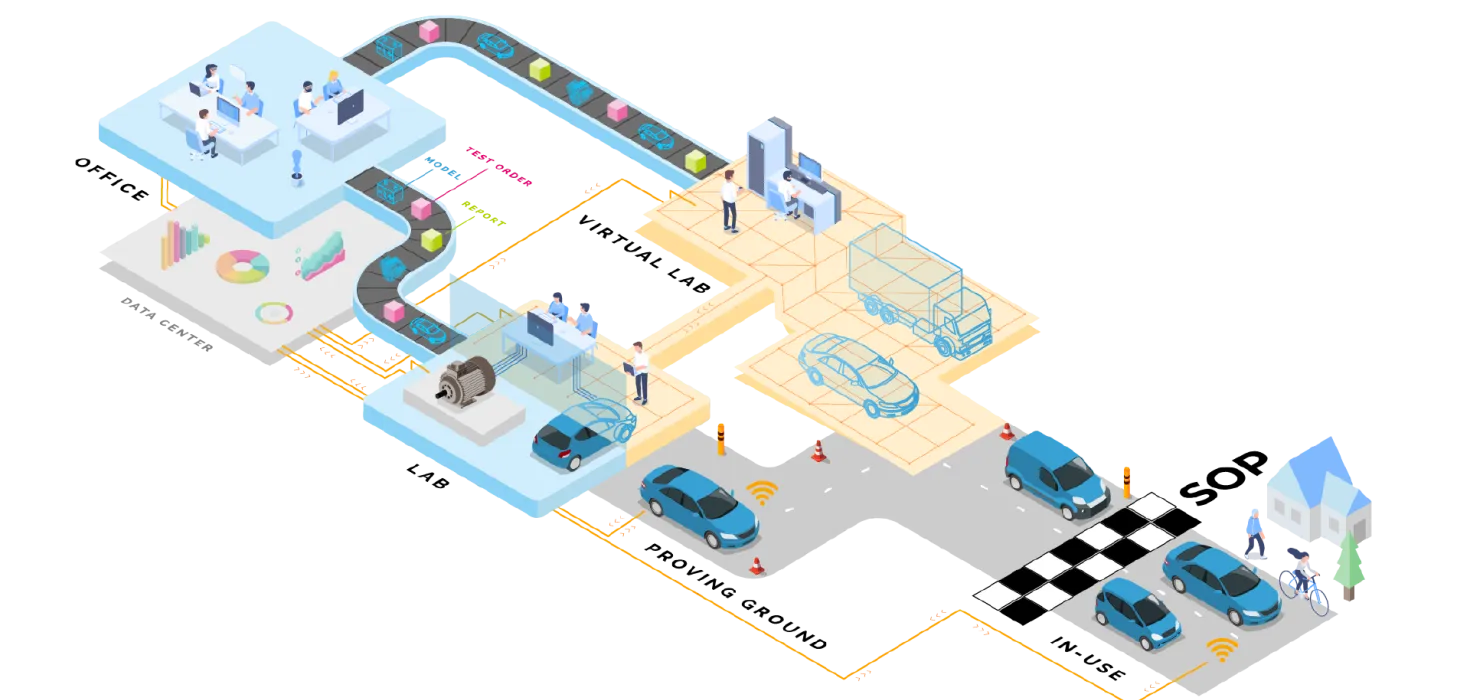

The automotive industry is no stranger to the complexities and demands of rigorous testing and validation. However, conventional testing methods often present significant hurdles in terms of time, cost, and scalability. Physical prototyping, while indispensable, entails lengthy cycles of design iteration, manufacturing, and testing, imposing constraints on innovation and agility. Moreover, the reliance on physical prototypes inherently limits the scope and depth of analysis, often failing to capture the full spectrum of real-world scenarios and operating conditions.

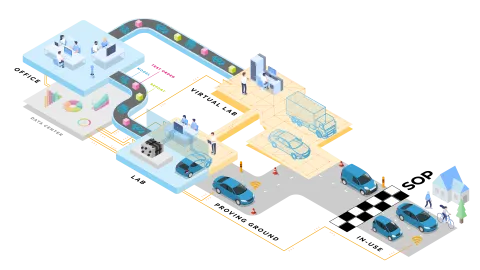

Virtual testing addresses these challenges head-on by offering a comprehensive and agile approach to development and validation. By harnessing the power of advanced simulation techniques and computational modeling, virtual testing enables engineers to explore a vast array of design configurations and performance scenarios within a digital environment. This capability not only accelerates development cycles but also significantly reduces costs by minimizing the need for physical prototypes and associated testing infrastructure

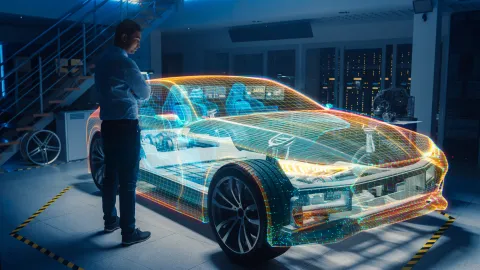

Furthermore, virtual testing empowers engineers to delve deeper into the intricacies of automotive systems, capturing nuances and interactions that would be challenging to replicate in traditional testing setups. From simulating complex thermal dynamics and structural behaviors to optimizing powertrain performance and vehicle dynamics, virtual testing offers unparalleled insights into the behavior of automotive systems under diverse operating conditions.

Seamlessly integrating advanced simulation tools and platforms into the development process. These solutions leverage state-of-the-art computational models and predictive algorithms to simulate a wide range of scenarios, spanning from component-level analysis to full vehicle dynamics simulation.

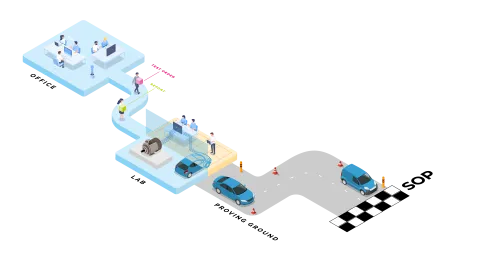

Key components of virtual testing solutions include:

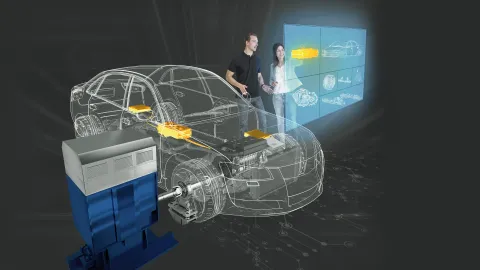

Predictive Modeling: Advanced computational models accurately simulate the behavior of automotive systems under various operating conditions, enabling engineers to predict performance outcomes and identify potential issues early in the design process.

Simulation Platforms: Robust simulation platforms provide engineers with intuitive interfaces and powerful tools for creating, executing, and analyzing virtual tests. These platforms support multidisciplinary analysis, allowing for seamless integration of mechanical, electrical, and thermal simulations.

Iterative Design Optimization: Virtual testing enables iterative design optimization, where engineers can rapidly iterate through design iterations, explore alternative concepts, and optimize performance parameters with unprecedented speed and efficiency.

Real-time Visualization: Interactive visualization tools allow engineers to visualize simulation results in real-time, facilitating deeper insights into system behavior and performance trends. This capability enables informed decision-making and rapid iteration cycles, ultimately accelerating the development process.

Virtualization has never been so important than now for accelerating the complex vehicle development. At AVL we employ it to help our customers shape the future of mobility.

- Gianluca Vitale, Global Business Segment Manager, Smart Calibration and Virtual Testing, AVL

Highlights

Moving steadily into the future: Find out what’s brand new in the field of virtualization.