Historically, calibrating a powertrain meant using multiple systems in parallel, each storing their results in separate files and requiring their own expert to parametrize the powertrain.

The interface between the systems was limited both in functionality and in performance. The result was twice the parametrization effort, slow data exchange between the systems, and multiple result files that had to be merged and time-synchronized afterwards.

MultiSync Technology has been developed to create a perfect development environment for dynamic calibration tasks. The solution enables all relevant transient recorder data to be contained in one result, time synced automatically. The powerful performance in terms of data acquisition frequency and number of channels ensures the results are complete and usable for both the specific task and for other users within the company.

Efficiency

Optimization of the inverter dataset for the best system efficiency of the inverter + e-motor.

Optimization

Optimize NVH and EMV while minimizing the impact on e-drive efficiency.

Traceability

Full traceability of all testbed and unit under test-related parametrization during the test.

One Result File

All relevant data in one result file, ready to use when the test is finished.

Easy Setup

One person to parametrize and execute the test without the need for multiple experts for the setup.

Central Parametrization

One centralized testbed parametrization standard combined with the flexibility needed for the individual development tasks.

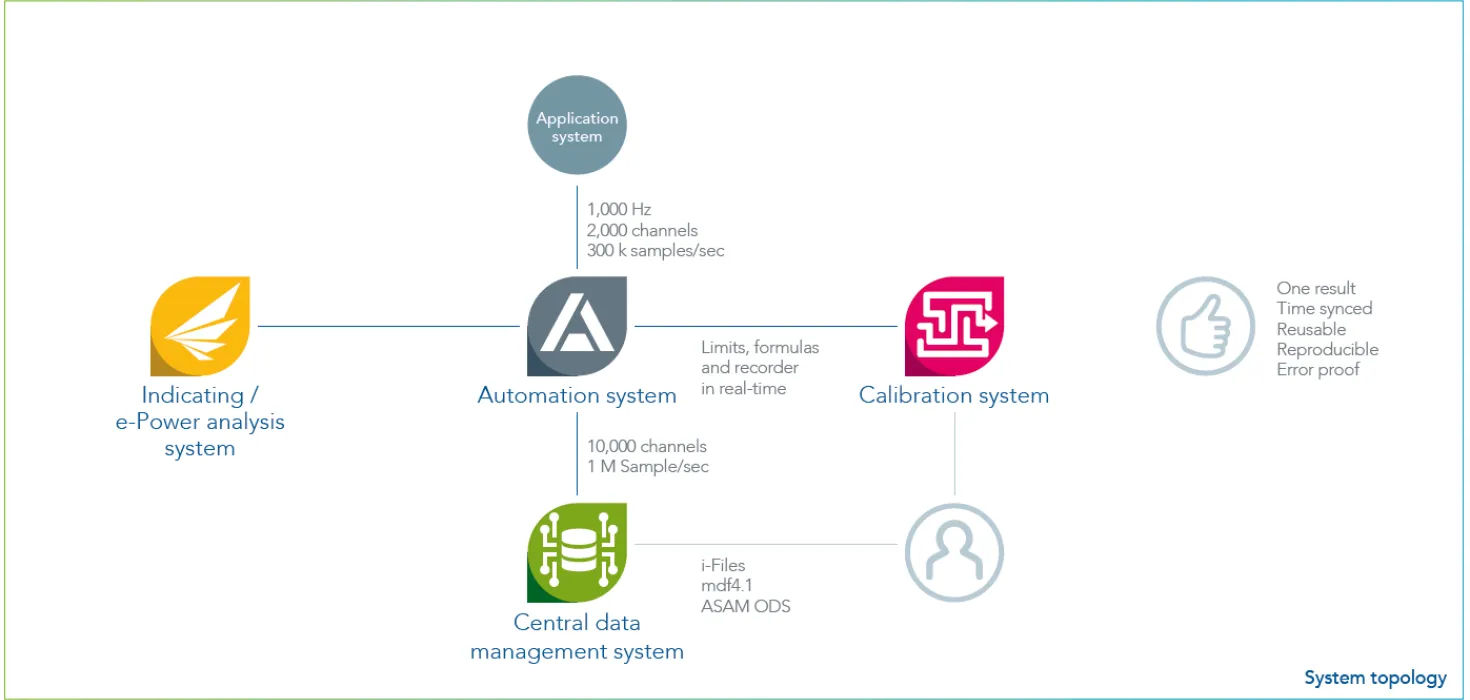

The main relevant systems interact in an optimized topology and the interfaces are raised to a new performance level. The network is centered on the automation system, which acts as a central data logger, collecting data in real-time from the measurement and calibration systems, and making it available centrally.

Synchronized, Complete Results

The automation system acts as a central data logger, collecting data in real-time from the measurement and calibration systems.

Change Propagation

Automatic adjustment of the automation system by the calibration, power analyzer, or application system during a running test (or the other way around).

Test Case Encapsulation

Complete encapsulation of a testing task can be transferred to another testbed to guarantee an identical setup.

Testing and optimization of electrified vehicles always involves multiple systems that interact with each other. Having the data from all of them ready-to-use, merged and time-synchronized, when the data is recorded is a must for solving development tasks efficiently.

– Mats Ivarson, Chief Engineer Testfield Innovation and Operation, AVL List