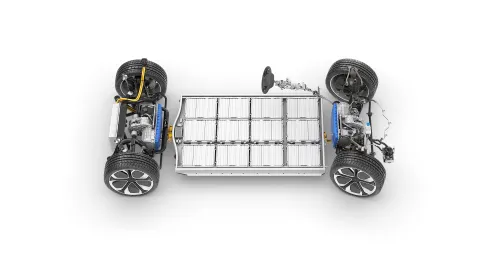

Overall System Understanding

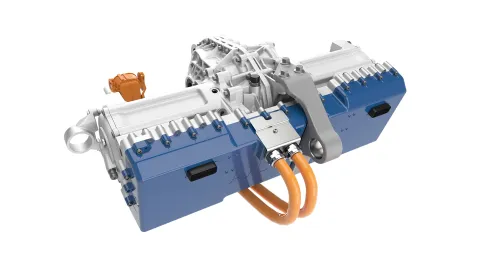

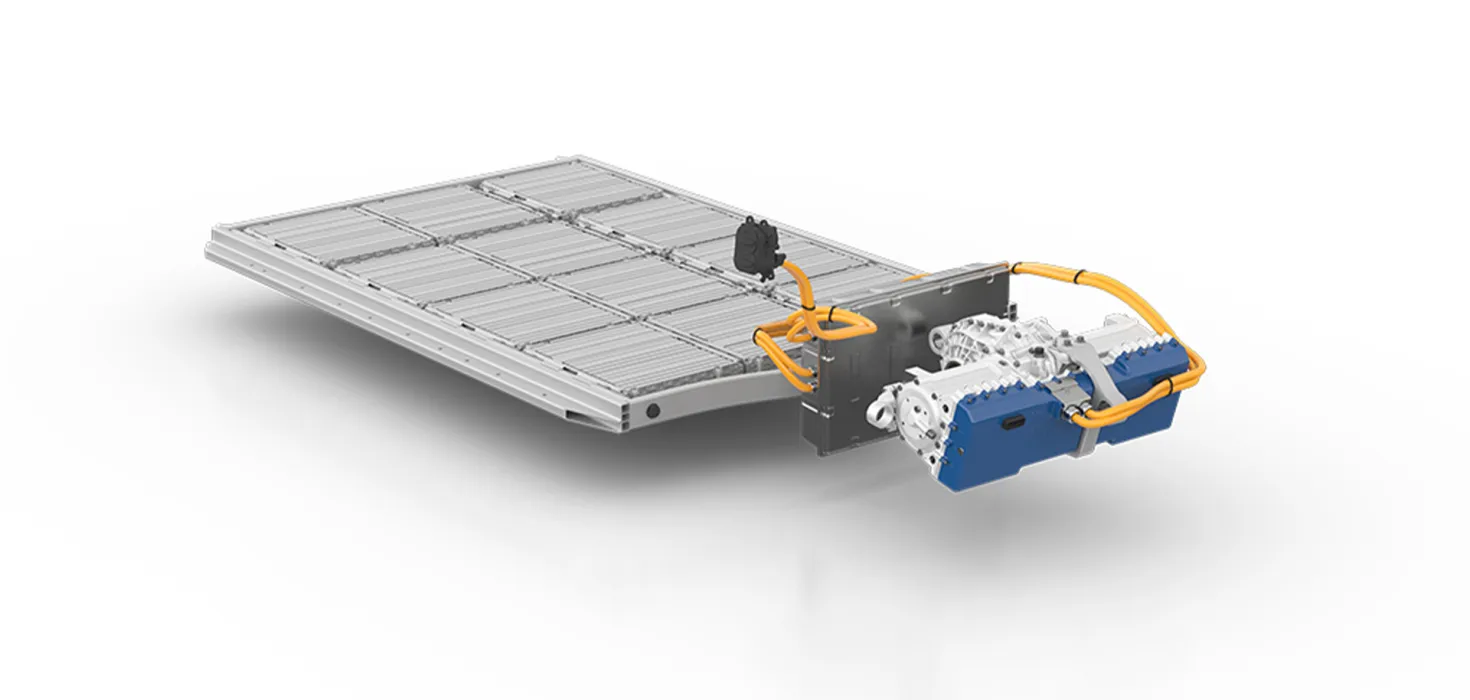

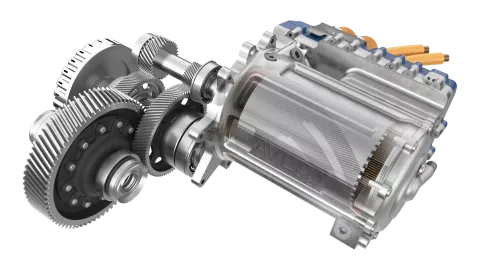

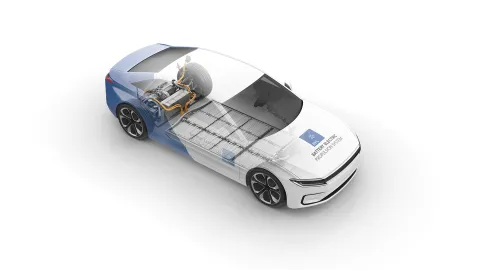

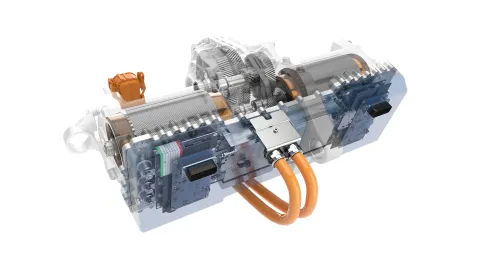

We view electric propulsion as an overall system. And develop it in the direction of an optimal overall solution that is perfectly integrated into the vehicle – in terms of both hardware and software.

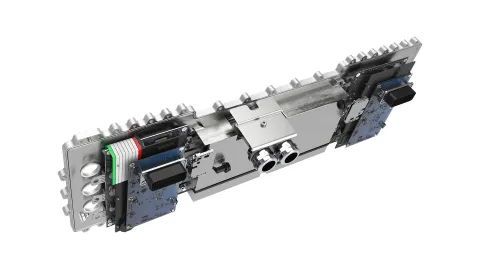

We provide support across all areas of the development cycle. From a blank piece of paper, to requirements engineering, simulation, design and development of individual components. As well as the whole electric driveline system or electric drive unit including the setting up of test systems as well as testing and validation. Further, we also cover series release of hardware and software.

With us you get manufacturer-independent product portfolio advice, benchmarking, support with requirements management, and the layout of system integration. Additional services relate to industrialization, the construction of demo vehicles and prototypes, as well as root cause analysis in the event of any problems with regard to customer developments.- From the individual component to the entire propulsion system.

We are ideally positioned for this with our three areas of competence for propulsion system development, test systems, and simulation.

Research and Experience

As a clear strategic focus, we invest around 10 % of our revenue in research and development. The focus is on making e-mobility even more attractive and sustainable. That means: reducing costs, increasing efficiency, more performance and power density, and less use of rare or critical materials.

In order to help shape the future, we also make use of proximity to universities and colleges. We are also involved in numerous public funding projects. This is how we familiarize ourselves with the latest technology trends, help shape them, and on this basis are able to offer our customers optimal solutions.

Through our collaboration with all major manufacturers, we are aware of the requirements of the automotive industry. We know the goals being striven towards and are a competent partner for your journey.

At AVL we ensure that the integration of the electric driveline components into a powertrain system is optimized in terms of the interaction of all its components and the resulting energy flows. Thus, we ensure minimum energy consumption which is crucial to reduce the burden on primary energy supply in our ongoing transformation towards climate neutrality.

- Gerhard Meister, Manager Business Field Electrification, AVL List GmbH