Im Stadtgut Zone E 4

4407 Steyr

Austria

At AVL, we are at the forefront of sustainable mobility, leveraging the latest technology and forward-thinking innovation. Our brand-new Tech Center in Steyr, Austria, embodies this vision. Designed to drive progress in powertrain and vehicle development, this state-of-the-art facility is fully equipped to support the next generation of on- and off-road commercial vehicles.

Our Location

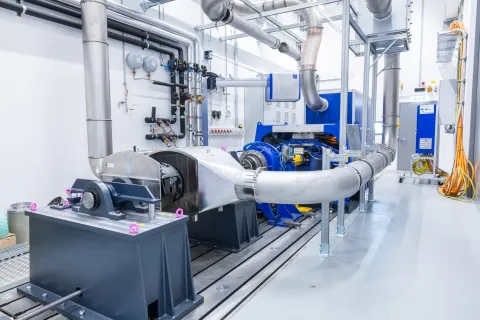

Our highly adaptable and flexible facility is designed to push the boundaries of commercial vehicle development.

Key highlights include: customizable testbed setups, high-performance testbeds, extensive real-world testing environment, electric vehicle focus and sustainability infrastructure.

Whether testing hydrogen technologies, optimizing high-torque systems, or refining vehicle integration, the AVL Tech Center Steyr is built to tackle the industry's most demanding challenges.

Sustainability is at the core of our Tech Center, with features that minimize environmental impact: waste heat recovery system and solar PV cells.

Flexible Spaces for Engineering and Testing

Electric Vehicle Focus

High-Performance Testbeds

Extensive Real-World Testing Environment

Sustainability Infrastructure

Waste Heat Recovery System

Solar PV Cells

Flexible Spaces for Engineering and Testing

Electric Vehicle Focus

High-Performance Testbeds

Extensive Real-World Testing Environment

Sustainability Infrastructure

Waste Heat Recovery System

Solar PV Cells

Testbed 1: Powertrain and Vehicle

This powerful and flexible 4-dyno testbed is designed for heavy-duty components (transmissions, axles and e-axles) and complete vehicles. Conventional, hybrid, electric, fuel-cell powertrains and vehicles can be tested, enabling simulation of real-world operating conditions. Additional reduction transmissions allows max. load/torque application. DC supply is available up to 800 kW for electrified components. Testcell 1 and Testcell 2 can be connected by a double leaf door to accommodate large vehicles. This ensures that even oversized vehicles up to a length of 14 m can be tested.

Testbed 2: Transmission and E-Axle

This testbed is designed for functional testing of transmissions and e-axles. DC supply is available up to 800 kW for electrified components. Additionally, the testbed is already being used for brake emission testing in accordance with the upcoming Euro 7 legislation for heavy-duty trucks and buses. The necessary components and procedures for these brake emission measurements have been developed to provide both testbeds and measurement services to our customers.

Testbed 3: Transmission and E-Axle

This powerful 2-dyno testbed is designed for testing of heavy-duty transmissions and e-axles regarding performance, efficiency, and durability. DC supply is available up to 800 kW for electrified components. Additional reduction transmissions allows max. load/torque application.

Testbed 4: Transmission, Axle, and E-Axle

This 3-dyno testbed is a high-performance system designed for testing transmissions, axles, and e-axles. DC supply is available up to 800 kW for electrified components. Additional reduction transmissions allows max. load/torque application up to 125 kNm per wheel/wheel-hub.

Testbed 5: Transmission and E-Axle

This powerful 2-dyno testbed is designed for testing of transmissions and e-axles regarding performance, efficiency, and durability. DC supply is available up to 800 kW for electrified components. Additional reduction transmissions allows speed and torque application in a wide range (10,000 rpm / 25,000 Nm).

Testbed 6: Vehicle Build, Commissioning, and Hot Cell

This testbed is designed for prototype vehicle build and commissioning, especially for battery electric and fuel cell vehicles with hydrogen technology. It is equipped with hydrogen and DC supply to handle battery electric, and hydrogen-powered systems but as well with an exhaust gas system for conventional vehicles. Additionally, the test cell can be used as a "hot cell" for ambient temperatures up to 45 °C.

With the new AVL Tech Center in Steyr, we are setting new standards for innovative and sustainable vehicle and drivetrain solutions. State-of-the-art infrastructure, flexible testing and real-world conditions make it a key milestone on the path to climate-neutral mobility.

- Stefan Heindl, Manager Tech Center Steyr

News

Our locations

4407 Steyr

Austria