Cheap Vehicles in All Vehicle Classes

At present, battery electric vehicles are predominantly found in the premium segment. The task at hand is to launch large quantities of appropriate solutions in other vehicle classes – with high sensitivity to costs. E-mobility should be affordable for everyone.

Our Research & Development department is working intensively on new concepts that will allow us to bring such vehicles to production maturity with limited use of raw materials and capital.

Continuing to Reduce Energy Consumption

End customers purchasing e-cars have three primary considerations: What is the car’s range? How quickly can the car be charged? What does the car cost? These three aspects are key differentiators.

By way of example, at AVL we think of the charging speed in terms of kilometers of range per minute, rather than kW charging capacity. This consumer-oriented perspective will also help us meet future requirements.

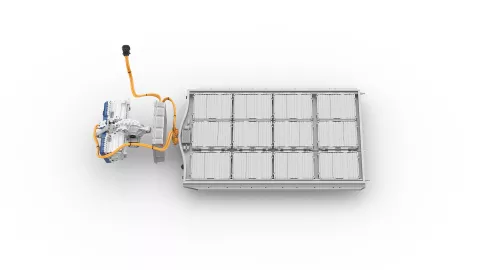

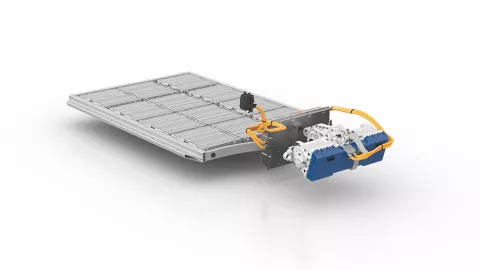

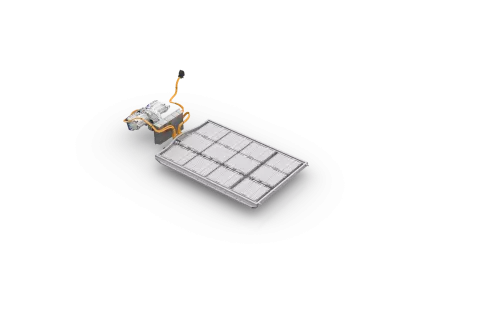

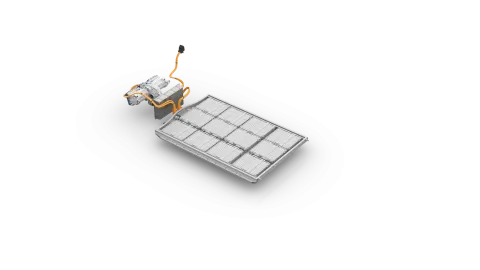

To reduce energy consumption, we are working on vehicle concepts that are lighter and more efficient – with smaller batteries that can be charged rapidly. Furthermore, our development activities have a strong focus on the overall energy management in the e-car, as well as on linking the various energy systems in the vehicle to minimize energy consumption. Systems thinking with systems engineering approaches, methods, and simulation tools is a fundamental key to success here: This is the only way to find the system optimum among the sophisticated individual components of the e-car – for minimum energy consumption and maximum system performance.

Our modular solutions include development support, testing and validation, simulation tools, and system integration. And they are tailor-made for your individual vehicle concept: from mild and plug-in hybrids – to battery electric and fuel cell electric vehicles that are based on dedicated platforms.

CO2 regulations, high energy and raw material costs drive the need to optimize the energy consumption of electric vehicles. With our system approach we relentlessly optimize the vehicle’s total energy efficiency to enable sustainable and affordable mobility.

Gerhard Meister, Business Field Leader, Electrification