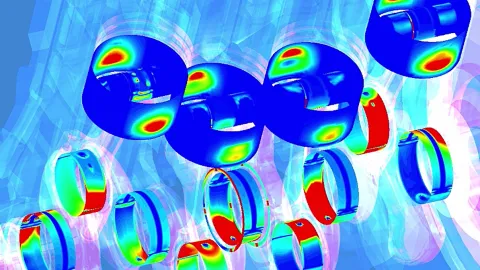

Efficiently and accurately calculating, analyzing and optimizing the behavior of slider bearingsSlider Bearings – Design, Optimization and Failure Analysis. Ongoing trends in combustion engine development like downsizing and downspeeding combined with increased power and torque, use of start-stop systems and hybridization lead to higher mechanical and thermal loads of all slider bearings in the engines. Together with the continuing demand for increasing fuel efficiency this has created the urgency to reduce frictional losses in the bearings to a minimum. In this webinar you will learn more about the capabilities of the AVL EXCITE™ elasto-hydrodynamic slider bearing model, suitable for a wide range of applications from highly loaded cranktrain bearings in the IC engine, high speed turbocharger bearings to slider bearings in transmissions.

Watch now

Gudrun Kreuzwirth

Christoph Schweiger