Faster Processes Despite High Complexity

Develop, verify, validate – these days you can complete these tasks much faster and better virtually than using components or systems that actually exist. Furthermore, narrow tolerance ranges can be illustrated much more precisely and efficiently as a simulation than in physical reality.

The Advanced Simulation Technologies (AST) division – one of the three pillars of AVL – provides you with everything you need for this. Virtual Twins give you detailed insights into the behavior and interaction of components, systems, and entire vehicles – long before they exist physically.

The simulation solutions are based on extensive knowledge and cover all aspects of vehicle development – irrespective of the vehicle type, propulsion type, or level of automation.

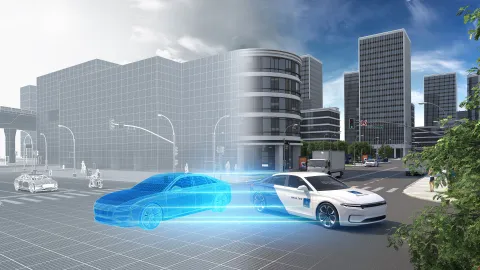

Your Development Advantage: The Virtual Twin

Simulations enable you to accelerate all areas of your processes: whether electrification, Advanced Driver Assistance Systems (ADAS) and autonomous driving (AD), emissions, vehicle technology, or data intelligence.

Your key here is the Virtual Twin – a virtual image of the vehicle or individual components that contains all relevant data, including associated control functions. The Virtual Twin covers the complete product, the mechanics, the electrics, its software, and the physical behavior. This allows you to identify problems and potential errors early on at every stage of development.

You can choose from:

-

Vehicle Simulation

-

E-Mobility Simulation

-

Automated and Connected Mobility Simulation

-

ICE Simulation

-

Software Offering

-

Simulation as a Service

Whatever your individual development needs are – no matter whether you are an automobile manufacturer, a supplier, or a new market player – you will always receive a tangible package that you can implement immediately.

Vehicle Simulation

In virtual chassis and body development, you can scrutinize general handling, as well as aerodynamics, water management in the rain and wading, and soiling from mud or snow.

Discover how simulation allows you to compare vehicle attributes with automated vehicle modeling, dynamic simulations, and correlation virtually.

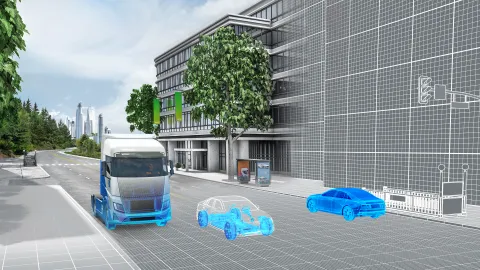

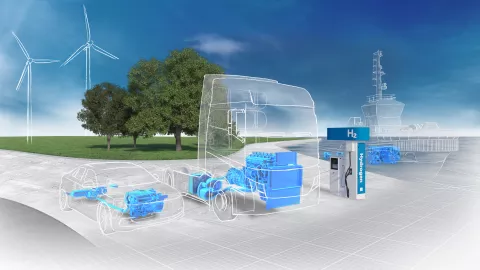

E-Mobility Simulation

You receive a comprehensive solution for simulating electric drives.

The combination of 1D and 3D models facilitates a detailed analysis of electromagnetics, e-motor dynamics, and transmission dynamics. NVH, efficiency, thermal, and durability analyses are also possible under realistic conditions.

You can access a depth of simulation down to oil splashing and lubrication analyses, enabling predictive efficiency and thermal analyses.

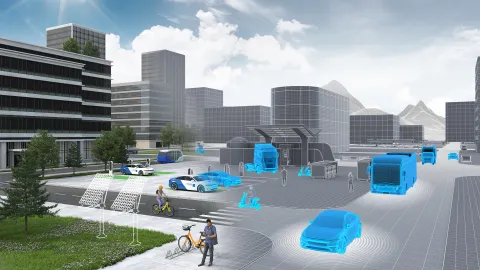

Automated and Connected Mobility Simulation

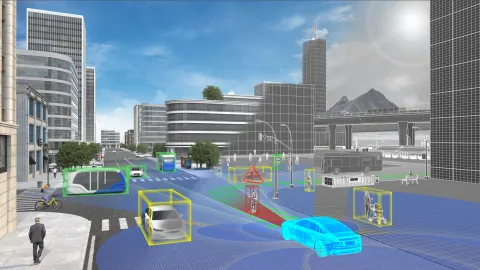

Here, you learn all about the model-based development of control systems, as well as the virtual calibration and validation of ADAS/AD and other vehicle control systems.

The integration platform connects your control functions with environment, vehicle, and sensor models, and supports all leading industry standards: FMI, SSP, XCP, OSI, OpenSCENARIO, OpenDRIVE, and more.

Automated test preparation and execution enables you to perform virtual, scenario-based tests, optimizations, and validations – locally on a PC, in the laboratory, or in the cloud.

ICE Simulation

With internal combustion engines (ICE) – regardless of whether they are hybridized – simulations give you greater efficiency and durability. This contributes to reducing loss of friction and optimizing overall vibration and noise levels.

You can also read how to achieve the main objective: the continuous development of combustion engine drive systems towards zero emissions and carbon neutrality.

Software Offering

You receive the simulation tools either as individual products or bundled as software packages.

For simulating electrification, for example, AVL eSUITE™ is your comprehensive license bundle that allows you to map all aspects of e-mobility virtually.

Simulation as a Service

You have access to a seamless simulation environment. Simulation web services enable easy integration into all IT environments. In addition, the sharing of model parameters and results facilitates collaboration transparently and controllably. The web applications give you a high degree of intuitive ease of use. They are available as cloud-based solutions 24/7 – without hardware or license restrictions.

We are your global partner in realizing the mobility of the future. A mobility characterized by its minimal impact on the environment. We offer you simulation solutions ranging from component to system analysis. As we are deeply integrated in the development process, our software solutions - tools and projects - enable you to master the challenges of virtualization.

75+

years of experience

in 26

countries worldwide

12,200

employees worldwide

68%

engineers and scientist

The mobility revolution is in full swing. This is not just about developing new, more sustainable propulsion systems. Rather, the entire development process is in upheaval - with simulation taking the lead.

Right now, it's important to understand the challenge that each of us - OEMs and suppliers alike - face when it comes to pushing the boundaries of both our design process and our engineers. As the number of different systems grows, departments and team structures are changing. We understand that. At AVL, we go through these processes as well, because we are not just software developers. We are also engineers and therefore users. We implement our knowledge in intuitive workflows, generators, wizards, and evaluations in our software and projects.