Gaining Insights Into Battery Degradation With the Virtual Twin

Published on August 19, 2024 · 9 min read

Ageing processes in the cell result in reduced capacity, which leads to a shorter range for the vehicle. Battery ageing also increases the internal resistance. This internal resistance leads to increased losses, which generate additional heat in the battery.

There are two primary types of battery ageing: calendar ageing and cyclical ageing. Calendar ageing describes the gradual reduction in performance and capacity over time. This process is influenced by various storage conditions, in particular the temperature and state of charge of the battery. An external temperature that is too high or too low, for example, accelerates the calendar ageing process.

Cyclical ageing, on the other hand, results from the way in which the battery is operated, in particular by carrying out charging and discharging cycles. The operating conditions during the charging process can have a significant impact on the life cycle of the battery.

Another important factor that affects the ageing of the battery is the choice of material. Different materials come with their own properties in terms of their cycle stability and energy density. For example, the currently popular LFP battery (lithium phosphate) has a higher cycle stability than the classic NMC battery (nickel-manganese-cobalt), but with a lower energy density.

The Primary Battery Degradation Mechanisms

Lithium plating is a phenomenon that can develop during charging at low temperatures. Dendrites of metallic lithium form on the anode, preventing further ion transport. These dendrites can also spread towards the other electrode and perforate the separator, leading to an internal short circuit. The loss of the active material is another effect of ageing, in which the material is no longer available for charge transport and thus becomes so-called "dead material" in the battery, which further impairs its performance.

Relevant Operating Conditions for Battery Ageing

The operating conditions play a decisive role in battery degradation and have a significant influence on their performance and service life.

The operating temperature is a key factor that affects battery ageing, especially during the charging process. To ensure optimized battery charging, it is therefore very important that the battery is already in the ideal temperature range or is heated or cooled accordingly before the charging process.

Another aspect is the charging capacity. A high charging capacity means high currents, which in turn can age the battery at low temperatures. For this reason, it is advisable to start slowly at low temperatures and adjust the charging power until the battery has warmed up to avoid ageing too quickly.

The charge-discharge cycles are also of great importance for the service life of the lithium-ion battery. It is often stated how many cycles are guaranteed until the end of the battery's life. To reduce cyclical aging, it is advisable to charge only in the optimum range and to shift the charging window to a range between 20 and 80 percent. A lower depth of discharge leads to an exponential increase in cycle stability. As a result, the battery is less stressed and no aging reactions are triggered, which can manifest themselves through non-reversible chemical processes such as gas formation and electrolyte loss.

Taking these operating conditions into account is crucial for the development of batteries with improved performance and service life. To this end, simulation models can be used to predict the effects of different operating conditions on battery ageing and support the development of efficient operating strategies.

Predicting battery degradation is essential to the development of efficient and long-lasting battery systems. Simulation models play a central role in predicting the effects of different operating conditions on the aging processes and developing corresponding optimization strategies.

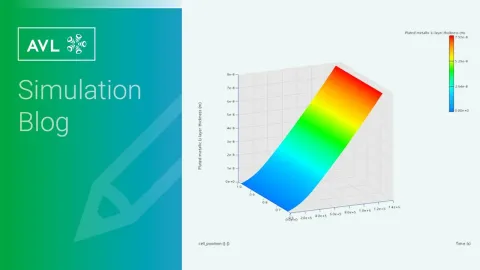

AVL offers advanced solutions with electrochemical models that make it possible to carry out long-term simulations with minimal effort. These simulation models are able to estimate and calculate the internal states of the battery, which is not possible with conventional physical tests on the testbed.

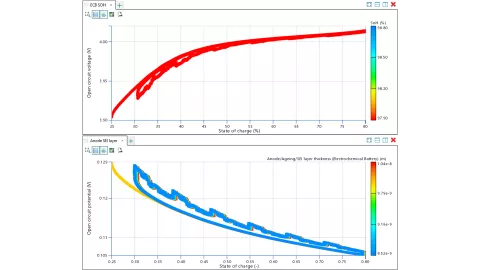

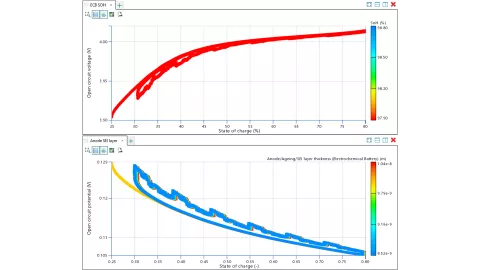

The anode potential, which cannot be measured on the testbed but can be calculated in simulations, is an important indicator of battery aging. Simulating battery degradation makes it possible to optimize charging curves and avoid ageing processes such as lithium plating by keeping the power close to the limit, for example during fast charging, without exceeding it.

By simulating charging and discharging strategies and adapting charging profiles to a validated aging model, questions about cycle stability can be answered over a long period of time. This allows users to simulate operating periods of several years and to make well-founded statements about the service life of the battery.

The parameterization of the ageing model is based on the data of an aged cell and is validated by comparison with the ageing curves of the real cell. As soon as only negligible deviations between the curves are detected, the testbed can be switched off and the simulation can continue to run independently. After decoupling the simulation model from the testbed, around six months of real time can be simulated in one month (depending on the hardware), resulting in considerable time and cost savings.

The growing importance of simulation in the battery development process goes hand in hand with the ongoing search for optimal materials for batteries. Materials such as LFP (lithium iron phosphate) are becoming increasingly popular due to their higher cycle stability, their safety and their longer service life compared to conventional cell chemistries. At the same time, simulation tools are constantly evolving and becoming better and better at mapping and parameterizing the effects of material selection and battery degradation processes.

While traditional testbed testing still plays an important role, the integration of simulation technologies offers the opportunity to save time and money and accelerate time-to-market. By combining the use of the testbed with software-in-the-loop systems, battery developers can make more informed decisions and optimize the performance of their battery systems. This results in faster time to market and supports the continued development of battery technologies for a more sustainable future.

Stay tuned

Don't miss the Simulation blog series. Sign up today and stay informed!

Learn More About This Topic

Stay tuned for the Simulation Blog

Subscribe and don‘t miss new posts.