Developing an efficient and durable electrolyzer stack involves overcoming four critical challenges:

Efficiency

Maximizing energy conversion efficiency from electricity to hydrogen is vital. Our stack designs integrate advanced materials and component designs to achieve an industry-leading electrical efficiency.

Durability

Ensuring the stack's longevity is a complex task, as customers expect lifespans of 40,000 to 80,000 hours - far exceeding traditional fuel cell requirements. We conduct Accelerated Stress Tests (AST) and develop degradation models to predict and enhance stack lifetime under various operating conditions.

Cost

Balancing advanced technology with cost-effectiveness remains a persistent challenge. By leveraging innovative designs and materials, we aim to deliver competitive solutions that meet both, technical and cost targets.

Hydrogen Pressure

Operating at 30+ bar differential pressure directly at the stack level reduces the need for mechanical compression, thus enhancing system efficiency and lowering costs.

With AVL, customers gain access to a full package of engineering and design services for PEM electrolyzer stacks, complemented by a global supplier base for stack materials and system integration. From initial concept to series-production readiness, we deliver tailored solutions that meet customer-specific requirements. Our offering includes:

- End-to-End Stack Development: From component materials to complete stack designs, from engineering to experimental validation, from concept to start-of-production.

- Proven PEM electrolyzer stack reference design: Utilizing AVL’s in-house stack design as starting point for commercial stack development projects

- Validation and Testing: Our global test centers are equipped with state-of-the-art test systems and proven testing methodologies (DVP) to validate and verify your PEM electrolyzer stack, and to guide you to a series-production release with confidence.

We are your independent engineering service provider with extensive experience in the development of PEM fuel cells and electrolyzers. With our expertise in stack design and system integration, we offer you the following advantages:

Streamlined Development Process

Our PEM stack reference design significantly reduces development time and costs, offering you a ready-to-build foundation for commercial stack development.

Technological Leadership

Partner with us to realize PEM stacks with industry-leading KPIs in efficiency, durability, and power density.

Access to Leading Supplier Technologies

We provide access to leading suppliers and supplier technologies in your region as well as globally

Enhance Your Value Creation

Insourcing the electrolyzer stack reduces your dependence on suppliers and increases your company’s value creation potential.

Reference Benchmarking Database

Benefit from our comprehensive reference benchmarking database to ensure competitive stack performance.

At the Heart of Innovation

Located in Vancouver, Canada – a global hub for PEM stack technology – our tech center keeps you connected to the forefront of innovation.

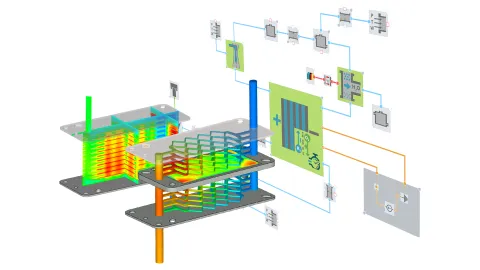

Stack Design and Optimization

Our experience in stack development includes completely custom-designed stacks as well as optimizing or troubleshooting existing stack designs. Cutting-edge models and simulation tools are an important element in achieving this.

Design Verification

We define Design Verification Plans (DVPs) based on our deep understanding of fuel cell and electrolyzer technology, and the failure modes and effects associated with these technologies. We execute testing service with our in-house electrolyzer testbeds.

System Optimization Support

In addition to designing complete systems, we excel in refining and enhancing existing systems. Whether it’s improving efficiency, extending lifespan, or addressing specific performance challenges, we deliver failure analysis, consulting, and engineering solutions.

Operating Strategy

Every stack design requires a well-balanced operating strategy to assure efficient operation, while making sure that the stack meets lifetime targets. Our stack/system interface team has the expertise and the experience to define the operating strategy your stack needs.

Material Characterization

We specialize in material characterization for electrolyzer stacks, providing critical insights for stack design and performance optimization. Our expertise spans beginning of life and degraded material analysis at macro and micro levels, supporting simulations, failure analysis, and benchmarking. Equipped with advanced tools and expert engineers, we drive durable, high-performance, cost-effective stack solutions.

Related Topics

We are constantly working on new solutions. The following might be interesting for you: