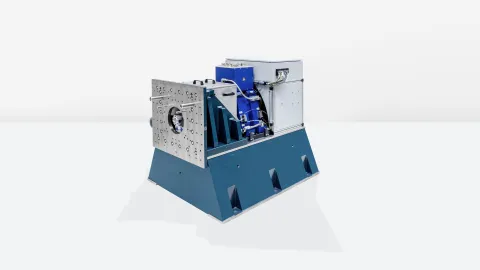

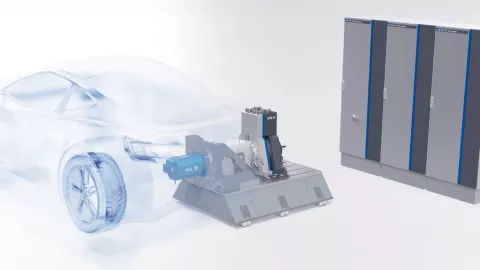

The power, torque and rotating speeds of modern traction e-motors are steadily rising, which also increases the levels of performance expected from capable testing solutions. In addition, e-motor test cases are often more demanding than their ICE counterparts. Some of them require the load system to provide high dynamics and short response times. The ever-increasing levels of e-motor performance favor future-proof and upgradable solutions in order to be ready for today’s and tomorrow’s testing demands. Furthermore, the shift from ICE-powered towards electrified vehicles is creating demand for the transformation of existing ICE test cells into e-motor test cells. This requires compact and size-optimized load systems.

Silicon carbide (SiC) technology power electronics provides high switching frequencies without current derating and makes additional motor chokes obsolete. An integrated control unit that uses Field Programmable Gate Array (FPGA) technology carries out all control tasks with a control frequency of up to 192 kHz. The AVL SPECTRA E-Motor Dynos are equipped with oil-lubricated bearings and hybrid cooling technology. High precision bearings reduce vibrations to extremely low levels. The combination of AVL SPECTRA converter and dyno form a highly capable load system covering test requirements with the highest rotational speeds as well as delivering high torque and power.

Property |

Unit |

|

Max. Speed |

up to 30,000 rpm |

| Nom. Torque | up to 650 Nm |

| Nom. Power | up to 550 kW |

| Inertia | 0.06 – 0.13 kgm² |

| Bearing Lifetime | > 20,000 h over full speed range |

| Vibration Level | < 1 mm/s over full speed range |

Highest Efficiency

Minimized switching losses result in increased efficiency, reduced carbon footprint and a decreased total cost of ownership (TCO).

Outstanding Control Performance

Control cycle times up to 1 MHz are required for highly dynamic test cases such as pothole driving.

Maximum Availability

Oil-lubricated, high precision bearings ensure lowest vibration levels and maximized bearing lifetime, no matter the operating range.

Space and Cost Saving

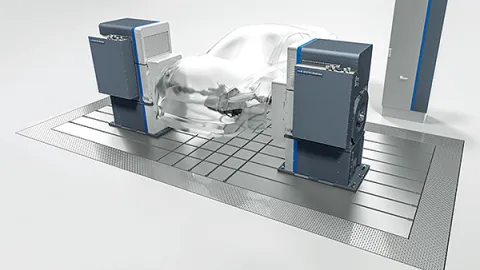

Up to 60 % smaller converter cabinet footprint enables the upgrade of existing engine test cells or reduces space requirements in new buildings.

Modular and Upgradeable

The modular design ensures upgradeability and is also highly beneficial when it comes to serviceability.

Superior Control

The ultra-fast 1MHz control cycle reduces dead times and enables the execution of highly dynamic test cases. In addition, the minimized current ripple reduces the occurrence of dyno torque ripple.

High Switching Frequency Without Derating

SiC power electronics are capable of high switching frequencies without the drawback of current derating and make additional motor chokes obsolete.

High-precision Bearing Technology

Highly precise and oil-greased bearings keep vibration levels to a minimum and ensure maximized bearing lifetime over the whole operating range.

AVL SIGNATURE Line – Brochure

Superior Technology – with AVL SPECTRA™ Inside.

AVL E-Mobility Testing Solutions – Brochure

From battery to full vehicle, from products, to test systems to whole test facilites – learn how we can support your testing needs.

AVL Spectra E-Motor Dyno PMM

DownloadAVL SPECTRA™ E-Motor Dyno Converter – Solution Sheet

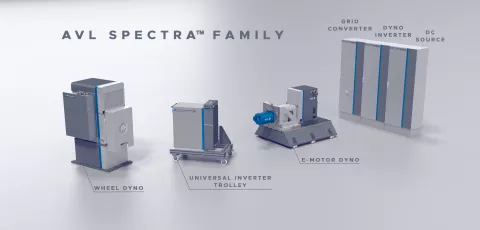

AVL SPECTRA™ Wheel Dyno – Solution Sheet

AVL SPECTRA™ Universal Inverter – Solution Sheet

Versatile testing device for future-proof e-motor and inverter development.