AVL CANLOAD is versatile and supports a wide range of test procedures and applications:

- Canister conditioning for international type approval of vehicles

- BWC (Butane Weight Capacity) & GWC (Gasoline Weight Capacity) testing

- Canister aging tests with real fuel as a mandatory precondition for EU certification

- Rapid loading cycles of canisters for the simulation of a refueling operation (ORVR)

- Canister pressure surge simulation (‘puff-loss’ testing) for the use in pressure tanks

- Dynamic purging / ‚real life‘ simulation using stored Ṽ/t curve profile

- Dynamic loading / ‚real life‘ simulation using stored ṁ/t curve profile

- Development tests to improve scavenging efficiency, especially for hybrid vehicles

- Influence analysis of the ambient conditions on the purging behavior of the canister

- Influence analysis of the AKF installation position on the loading or purging behavior of the AKF

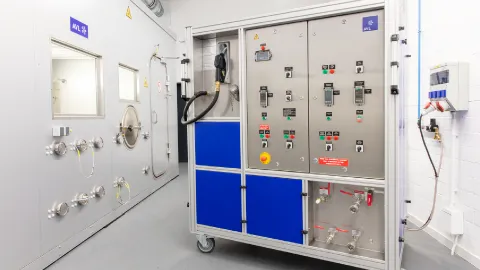

CANLOAD 1L-B

Single-line System for BWC (Butane Weight Capacity) tests as required for vehicle certification.

CANLOAD xL-B

Multi-line conditioning system for standard BWC testing, canister conditioning, as well as research and development (R&D) applications.

CANLOAD xL-BF

Multi-line fuel vapor/butane canister conditioning system for vehicle certification, diurnal tests and R&D applications.

- TCP/IP based AK interface

- Continuously adjustable loading rates between 5 -300 g/h

- Continuously adjustable loading rates for fast loading - 3000 g/min

- Large purging range (2 l/min up to 100 l/min)

- Continuously adjustable, MFC based loading rate

- Continuously adjustable, MFC based butane/nitrogen mixing ratio

| Property | Unit |

|

Dimensions (W × H × D) |

972 mm × 2127 mm × 1046 mm |

| Loading rate | max. 300 g/h (Standard) max. 3000 g/h (Option fast load) |

| Range MFC | 0.04 – 2 L/min (Standard) 0.4 – 20 L/min (Option fast load) |

| Loading / Purging | Max. load rate butane/fuel 220 g/h Min. load rate 15 g/h Max. load rate ORVR butane/fuel 2500 g/h Purge volume flow ambient air UUT 0 – 150 l/min |

High Degree of Automation

The modern automation software offers a structured user interface and can be flexibly configured and expanded.

Legislation Compliance

AVL CANLOAD offers integrated templates for test procedures required by the current legislation in Asia, America and Europe.

Modularity of the System

The system is designed in a modular way. Numerous options are available and it can be expanded to up to four test lines.

Robust and Safe

AVL CANLOAD offers a high level of safety with an automatic LeakCheck procedure and the integrated explosion safety.

Unmanned Operation

The system is designed to operate unattended 24/7 with its fully automated data acquisition system and safety modules.

Options for Every Application

Whether the system is used for vehicle certification or in pre-development, the various options allow loading with butane/nitrogen (CANLOAD xL-B) or additionally with fuel vapor/nitrogen (CANLOAD xL-BF) to enable a wide variety of test procedures.

Modular Design

The system can be expanded to up to four self-sufficient conditioning units. The modular design of the system also allows additional units to be retrofitted to meet new requirements.

Safety in Test Operation

Equipped with integrated plausibility and monitoring functions, the system offers a high degree of measurement and work safety.

Solution Sheet Evaporative Emission Testing

Learn more about portfolio of products for evaporative emission testing.