Vehicle testing is becoming significantly more complex. Electrified, hybrid and hydrogen powertrains introduce new validation requirements, while global emission standards continue to tighten. At the same time, development cycles are shortening – putting increasing pressure on test facilities to deliver accurate and compliant results faster than ever before.

To remain competitive, testbeds must ensure maximum utilization, reproducible data quality and the flexibility to support evolving propulsion concepts. A powerful and scalable automation and control system is therefore essential to meet today’s demands and future regulatory requirements.

Extended Testing Cycles

Due to the extended test cycles for electrified vehicles (discharging energy storage), efficient use of the testbed becomes even more important

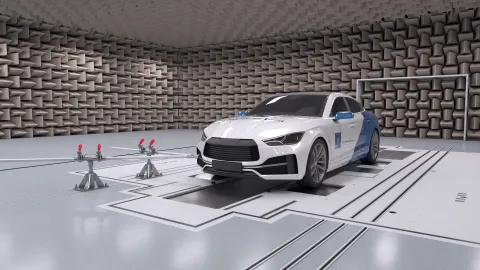

EMC Testing

Growing system complexity and high-voltage architectures increase the importance of reliable, repeatable EMC validation.

NVH Testing

Noise emissions are becoming increasingly important in all vehicle classes and appropriate sound design is still essential

Automation of Endurance Testing

Shorter development timelines demand continuous, automated endurance testing to reduce manual effort and ensure traceability.

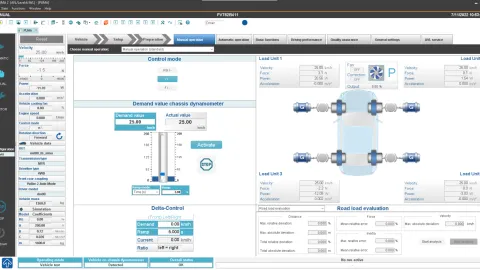

AVL Vehicle Testbed Automation and Control integrates measurement devices, simulation models, and control systems into a consistent automation environment. In combination with AVL ROADSIM chassis dynamometers, it enables precise axle synchronization and realistic vehicle behavior across all propulsion concepts, including conventional and fully electrified systems for motorcycles and heavy-duty trucks.

The system supports a wide range of applications, including emissions and energy consumption certification, performance and endurance testing, electromagnetic compatibility (EMC), noise, vibration, and harshness (NVH), and climatic validation. Automated workflows ensure efficient execution, reproducible results, and optimized testbed utilization.

When combined with AVL iGEM 2™, the solution expands to include a comprehensive certification environment. Long-term software maintenance contracts ensure continuous performance, stability, and lifecycle support.

Global Certification Confidence

The system supports worldwide certification standards and is proven in use by leading authorities such as CARB (US), KBA (GER) and TÜV. This ensures regulatory security and reliable approval processes.

Advanced

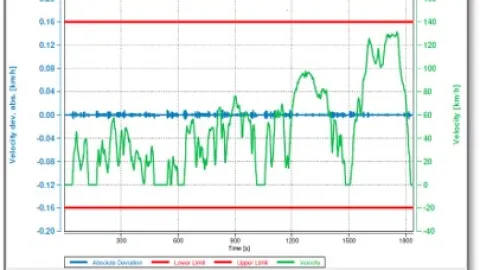

Quality Assurance

Automated quality assurance procedures verify test stand functionality according to defined specifications. This increases reproducibility, reduces errors and safeguards process quality.

Maximum

Testbed Utilization

Intuitive workflows, precise load control and extensive automation enable fast task execution and optimized resource usage. This increases productivity and shortens overall development timelines.

Workflow-Oriented User Interface

An intuitive interface designed for vehicle testbed operation. It guides operators through setup and execution, reducing rigging time and minimizing errors.

High Performance Control

Advanced control enables realistic road simulation. Precise distance behavior and axle synchronization ensure reproducible and reliable test results.

EMC Testing Capabilities

Integrated turntable control and velocity ramps support efficient EMC investigations. Synchronized data acquisition enables fast identification of load-related effects.

NVH Testing Precision

Accurate roller positioning and phase control ensure precise alignment and stable, repeatable NVH measurements.

Our systems fulfill all legally required quality procedures for chassis dynamometer certification and are approved by leading authorities worldwide, including CARB, KBA, TÜV and EPA. Built on AVL’s proven automation platform, which has been delivered more than 7,000 times, they ensure long-term security, the highest level of accuracy, and outstanding performance.

– Arnold Berger, Managing Director, AVL Zöllner GmbH

AVL Vehicle Testbed Automation and Control Solution Sheet

Vehicle Testbed Automation and Control