The performance of electrified powertrains is strongly shaped by real-world influences such as gradients, lateral inclinations, and climatic extremes. These factors directly affect thermal behavior, lubrication, energy consumption, and durability. Without the ability to reproduce them, test results remain incomplete and critical risks may only emerge in costly later stages.

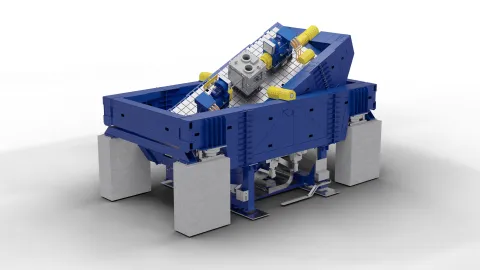

AVL Tilting Powertrain TS™ addresses this by enabling realistic gradient and load simulation in the lab. Its dynamic two-axis platform replicates uphill, downhill, and lateral inclinations with high precision, while optional climate control adds another layer of realism. This innovation broadens the scope of powertrain testing, enabling earlier validation, deeper insights, and the development of efficient, robust, and future-proof e-mobility solutions.

The AVL Tilting Powertrain TS™ is engineered for front-loading the development and validation of hybrid and electric powertrains as standalone units without requiring a full vehicle. By extending conventional powertrain testing with realistic road gradient and optional climate simulation, it closes the gap between lab validation and real-world operation.

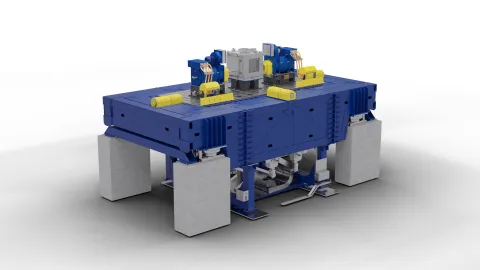

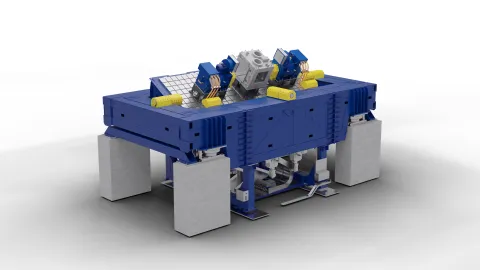

At its core is a dynamic two-axis tilting platform that can reproduce both longitudinal (uphill/downhill) and transverse (lateral inclination) gradients. Typical ranges are ±30° to ±45°, with tilting speeds of 5°/s to 15°/s, which mirror dynamic manoeuvres. Modern electric servo drives replace hydraulics to provide greater precision and energy efficiency, as well as making maintenance easier. The weight- and stiffness-optimised platform accelerates large masses, while AVL PUMA 2™ provides real-time setpoints based on the road profile and test cycle.

In order to impose realistic loads that do not physically exist on a testbed, our tilting test system incorporates wheel load dynamometers to simulate rolling, air, gradient and acceleration resistances. Typical configurations use up to three dynamometers, with high-voltage (HV) components supplied via a battery emulator/simulator. In hybrid testing, one dynamometer can emulate the internal combustion engine (ICE). Each wheel load unit delivers up to 7,000 Nm/440 kW for light-duty applications and up to 40,000 Nm/625 kW for heavy-duty applications. Target load torques are generated by real-time models in AVL PUMA 2™ that consider vehicle and route parameters.

An integrated climate enclosure for the powertrain under test can reproduce ambient temperatures ranging from -40 °C to +80 °C. This enables evaluations that consider climatic conditions in addition to gradients and loads, which is critical for accessing thermal behavior of powertrains in terms of efficiency and durability.

Tilting testing significantly enhances the capabilities of conventional powertrain validation. It enables the precise verification of thermal management under combined gradient, load, and temperature conditions as well as the assessment of lubrication and fluid supply under sustained inclinations – an essential factor for heavy-duty and off-road applications. Additionally, it facilitates the development of control algorithms that remain stable in dynamic, real-world driving scenarios. The result is earlier and more comprehensive validation with high reproducibility, fewer vehicle prototypes and a shorter time to market.

The AVL Tilting Powertrain TS™ is the first solution to combine gradient, load, and climate simulation in one system. It gives OEMs and suppliers a unique advantage in mastering the complexity of electrified powertrain development."

– Christian Wooning, System Line Manager, AVL Deutschland GmbH

With AVL Tilting Powertrain TS™, OEMs and suppliers gain a powerful tool to accelerate electrified powertrain development. By combining gradient, load, and optional climate simulation in a controlled environment, the system delivers highly reproducible results that reduce reliance on costly vehicle prototypes. This enables earlier validation, minimizes risks, and shortens overall development cycles.

Beyond process efficiency, the system enhances result quality and test coverage. It provides detailed insights into thermal management and lubrication behavior to master energy efficiency and durability of e-powertrains, while also safeguarding performance under demanding conditions. Whether for passenger cars, heavy-duty trucks, or off-road applications, our tilting test system ensures electrified powertrains meet market, regulatory, and customer requirements.

Key Benefits at a Glance:

- Realistic simulation of uphill, downhill, and lateral driving conditions

- Holistic testing by combining gradient, driving resistance, and climate simulation

- Early validation of thermal management to enhance energy efficiency

- Verification of lubrication and fluid supply under sustained inclinations

- Reduction of costly prototypes and real-world test mileage

- High reproducibility and controllability of complex test scenarios

- Faster time-to-market with lower development costs