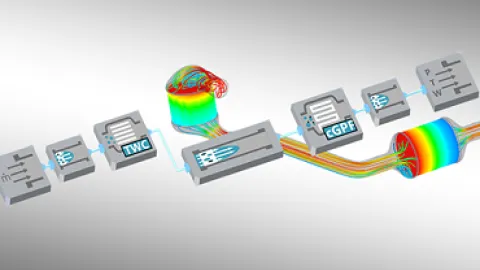

For many years, the automotive industry has been under constant pressure to reduce emissions from internal combustion engines. To meet current and upcoming legislation goals, exhaust gas aftertreatment systems must be highly efficient right from engine start. For engineers it is essential to have the optimal tools supporting them in every phase of the development process. This means all the way from concept selection, to component optimization, calibration and testing. AVL’s simulation solution provides the most comprehensive set of functionalies on the market embedded in a modern, intuitive framework. It can model all kinds of exhaust gas aftertreatment systems efficiently to find the optimum for every use case. A model library offers the most common aftertreatment components with pre-defined settings, including reaction kinetics. Simulation models are executed in transient mode in 1D or 1D+1D, depending on the washcoat layering. Aftertreatment models can be set up and operated stand-alone with given input traces of engine raw emissions or any measurement data. But it is also common practice to invoke them into the thermodynamic network of an engine or even a vehicle model. In such cases, dedicated co-simulation techniques are applied to match the computational requirements of the different system models. To support a cost-efficient and at the same time effective RDE compliant calibration of aftertreatment systems, AVL CRUISE™ M offers real-time proven plant models. Executing these models in HiL environments significantly reduces test bed occupation and on-road testing.In this webinar, AVL’s experts will provide an overview about the tool’s newly released EAS system simulation capabilities, including model setup and execution, simulation monitoring and result anlysis. The presented show case is a EURO 6 Gasoline aftertreatment system being part of a thermodynamic cycle simulation model.