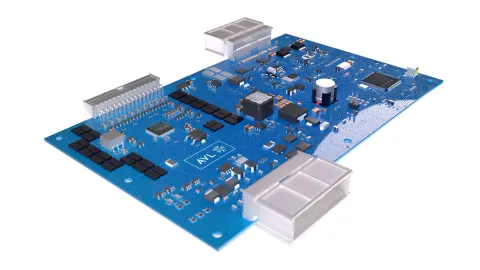

Since 2007, we have concentrated on developing safe, cost-efficient, environmentally friendly battery systems with high energy density. Throughout the years, our focus has been on producing top-quality products with a strong emphasis on functional design and innovative production processes. We devise strategies for individual assembly steps and flexible small-batch production of modules and battery systems. The projects listed below represent just a few examples of our extensive work:

- AVL Lighthouse

Our internal project to advance electrification by focusing on battery, EDU, and thermal system development and integration. AVL also leads the integration of E/E systems, control systems, vehicle aerodynamics, and chassis enhancements.

- McLaren Speedtail

Battery pack development project from initial concept to start of production (SOP), incorporating modules into the battery pack for hybrid electric vehicle. The project was executed at the AVL Battery Innovation Center, where small series of battery packs were manufactured.

- LG

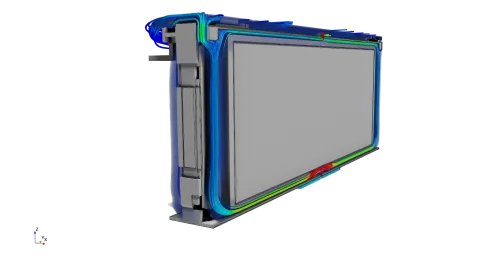

Pouch module with a coated aluminum monoframe. Now produced in very large batches and installed in the Audi e-tron and Porsche Taycan, for example.

Development methodology

At AVL, we have the expertise, methods, and tools for the entire development process. These include simulation tools and service, virtual testing and validation, creation of prototypes, and integration into the complete vehicle.

Innovative capability

We have been actively involved in automobile production for more than 75 years, and have optimized our processes for the swift transition from innovation to series-ready products. For batteries in particular, we focus on parallelization of functional and production process development.

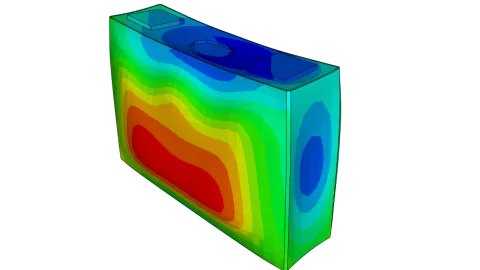

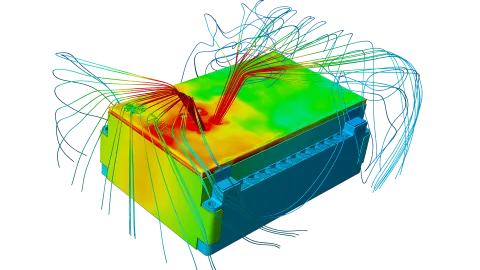

Our innovative battery concepts allow us to reduce CO2 emissions and increase the 24/7 safety of battery-electric vehicles. The key phrase is: no propagation. If a thermal runaway looks likely at cell level, flames must not spread to neighboring cells. Battery design of this type requires a detailed, careful development and verification process. We have developed a unique simulation methodology to realize this swiftly and in a cost-efficient manner. This combines physical tests at cell level with simulations at module and pack level - including the corresponding vehicle interfaces.

AVL develops next-generation battery systems through a holistic, simulation- and data-driven methodology. We enable our customers to achieve high energy density, functional safety, and performance targets—while reducing complexity, cost, and time-to-market.

Our expertise spans the full development lifecycle, from concept and system design to industrialization, always with a focus on sustainability, safety, and future-proof architectures.

- Paul Schiffbänker, Director Product and Business Development Battery

As an independent service provider, AVL has been a leading battery technology company for nearly two decades.

From the electrode to the pack, we provide complete vehicle integration. We are pioneers, especially with regards to safety, we are already able to realize the no propagation objectives for the next generation of battery electric vehicles.

Our Battery Innovation Center (BIC) in Graz, opened in 2021, added another key future platform to our portfolio, enabling us to provide the best possible support for the automotive industry and its suppliers during the conversion to electromobility. The facility, which covers an area of 1600 square meters, supports all of AVL’s expertise in innovative battery concepts around the world, both in terms of functionality and production process development.

Whitepaper: China Regulation GB38031

DownloadOur global network of engineers and scientists provides the best possible connections for all vehicle disciplines. Wherever you are located – we are able to provide local support.

20+

years of experience in battery development

650+

engineers in this segment around the world

900+

executed battery projects

25 %

year-on-year growth in battery development

45

global tech and engineering centers

10+

sucessful series developments

News

Moving steadily into the future: Find out what’s brand new in the field of battery development.