CO₂ Reduction

Emissions are composed of a variety of gases and particulates that must all be considered in the quest for clean mobility. Greenhouse gases, such as CO₂, CH4 and N2O are known to have a significant influence on climate change and therefore OEMs face tough legislation for its reduction.

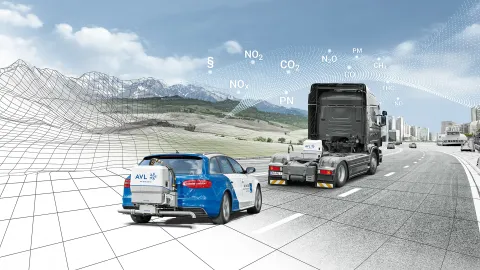

In order to meet these requirements, innovative technologies for reducing (ideally avoiding) and measuring CO₂ are required. This also includes devices for measuring the electrical energy flow of electrified powertrains. In heavy commercial vehicles as used in the transport industry, the CO₂ emissions of diesel engines are verified worldwide under simulated conditions, in real vehicles and on the road. This means that tests, measurements and simulations must take into account the entire vehicle, as well as the entire powertrain.

Dedicated hybrid engines for instance represent a valuable contribution to CO2 reduction. The utilization of the synergies in an electrified powertrain enable to maximize the ICE efficiency up to 45% (BTE, Gasoline Engine, Passenger Car Segment) in stoichiometric operation.

Pollutant Emission

Pollutant emission are a threat to human health, especially in large cities. The threat is made worse by the density of pollutant sources and their proximity to people, making it a local issue that must be solved globally.

In order to meet this challenge , the development effort for effective combustion and aftertreatment systems is constantly increasing. This is largely due to the demands for better performance imposed by emission legislation. New ways must therefore be found to increase system performance while reducing the complexity of development tasks as well as costs and time spans.

Our Approach

Tailoring solutions to perfectly fit the specific needs of each customer requires a holistic approach that considers as many variables as possible. That's where we can help. Our comprehensive product portfolio delivers solutions for every requirement in the development process of a modern engine, vehicle, or powertrain to support creating the optimal solution.

Nations around the world have made it their goal to reduce pollutants and greenhouse gas emissions. As a result, the automotive industry is facing increasingly stringent regulations. However, because requirements differ from market to market, OEMs must find solutions that ensure robustness, reliability, cost efficiency and compliance around the world.

We at AVL have all the simulation, engineering, and testing solutions to meet emission legislations worldwide. We offer the right answer for every market and help OEMs achieve CO₂ targets.

Conventional ICE-based Powertrains

The internal combustion engine will continue to play an important role in future propulsion systems for many years to come. With the right balance of technologies, it is part of the solution for greenhouse gas emission reduction in combination with ultra low pollutants.

From combustion system to exhaust gas aftertreatment devices, we are able to make ICE-based powertrains cleaner than ever before. Our portfolio of tools and processes examines every component and system – right up to the entire vehicle – to make sure every part is optimized to deliver efficiency and performance and has a minimum impact on the environment.

Comprehensive Combustion and Emission Simulation

Our simulation solutions cover the entire engine development process, from start to finish – expanding even to integration into the vehicle and drive cycle performance, efficiency and emission prediction. We are experienced in developing tools to help you manage complexity and continuous component and system optimization while reducing cost and time-to-market.

Powerful Turnkey Products for Emission Measurement

Increasingly stringent emission legislation requires enhanced emission testing systems. Our powerful and accurate testing solutions are available whenever and wherever you need them. They are designed to be used in the lab and on the road.

Hybrid Powertrains

Hybrid powertrains have the potential to reduce greenhouse gas emission substantially. Their added complexity of course increases the development and testing effort and time-to-market significantly.

At AVL, we are experts at integrating systems. The best hybrid solutions do not merely combine an ICE with an e-machine. Instead, they are comprised of systems that complement each other to deliver the optimal combination of characteristics in order to achieve desired targets.

Virtual Development of Electrified Powertrains

Our component simulation tools not only allow to develop and optimize fuel provision, gas exchange, combustion and emissions of IC-Engines, but also handle electromagnetism, electrochemistry and electrothermal behavior of e-machines and batteries. System simulation tools support control function development and calibration of control units for both combustion engine and electric motor.

Modular Testbeds for High Flexibility

We always keep your needs in mind whenever we design our products and services. All our modular testbed solutions are flexible enough to be tailored to any hybrid architecture. This enables the combustion engine and the electric drive to be tested at the same time.

Alternative Fuels for CO₂-free or CO₂-neutral ICE operation

To meet the challenges of improving air quality, the industry must continue to improve the performance of conventional powertrains while driving powertrain electrification. Complementary to this, alternative fuels have great potential as energy sources in new, cleaner powertrains.

Renewable fuels are a reasonable contributor towards global CO2 reduction. The increasing variety of fuels make the development, calibration, testing and validation of future powertrains even more complex. We have the tools, processes and methodologies to help OEMs build engines and systems that make the most of this new generation of alternative fuels.

The Power of E-Fuels for CO₂-neutral ICEs

E-fuels are gaseous or liquid fuels for internal combustion engines that are created by transforming renewable electricity into chemically bound energy carriers. Using e-fuels can help to convert today’s combustion engines into CO₂ neutral powertrains.

Mastering Alternative Fuels with AVL

To make your future powertrain ready for alternative fuels, we offer a range of certified emission measuring equipment, software and calibration tools. We guarantee highest level of professionality by adding simulation to all tasks. This enables highly accurate analyses and optimization of the combustion system.

Hydrogen for CO₂-neutral ICEs

Using hydrogen as a fuel requires finding answers to a number of questions. These include, how to arrange the hydrogen/air mixing in the combustion chamber, shall the engine be operated on richer or leaner air/fuel ratio, what charging concept is needed to achieve performance and emissions targets, and others.

Our engineers have engaged in research and eventually developed the AVL Hydrogen engine, a powertrain for CO2-neutral goods transportation, capable of ensuring high system efficiencies for heavy duty operation, high tolerance to low purity fuel and gas engine like reliability. Simulation supported design decisions from the very beginning. Dedicated hydrogen engine test systems have been developed in parallel.

Our global infrastructure and our network of experts in all markets around the world not only give us an understanding of the current requirements of legislation. It also allows us to understand trends, form opinions and get an idea of the direction in which they will develop in the future. This is happening both regionally and globally.