Water Spilling Cases in PreonLab: Protecting Electrical Components Inside the Cockpit

As smart cockpit electronics become increasingly common, the risk posed by liquids, such as spilled drinks or water leaking from sunroofs, has emerged as a significant reliability concern. Traditional testing with physical prototypes is not only time- and labor-intensive, but also limited in its ability to represent all possible scenarios.

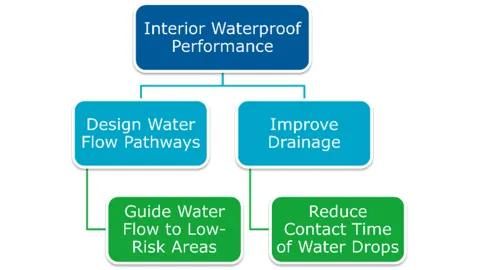

PreonLab addresses these challenges with a particle-based simulation method. It enables the accurate reproduction of complex liquid behavior inside the vehicle. Engineers aiming to improve interior waterproofing must focus on two aspects:

Optimizing water flow paths to direct liquid toward low-risk or designated drainage areas.

- Enhancing surface hydrophobicity by increasing the contact angle and minimizing the contact time of droplets on sensitive surfaces.

PreonLab provides a suite of simulation outputs to support interior waterproof design improvements:

- Current Wet Surface & Area Ratio

Identifies parts of the interior currently in contact with splash water and their area ratio, visualized in green.

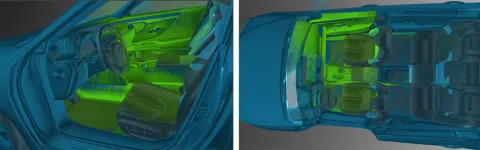

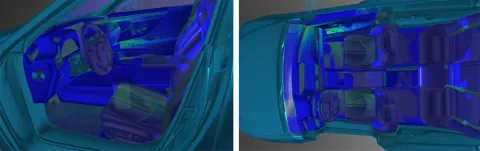

- Cumulative Wet Surface Information

Shows all interior surfaces exposed to water throughout the entire splash event. The areas highlighted in green in the figure below represent all interior surfaces in contact with water.

- Wet Time Output

Highlights how long water remains in contact with various interior surfaces, aiding durability assessments. The areas highlighted in green in the figure below represent interior surfaces with longer contact times with splash water.

PreonLab can simulate virtually any water spray condition. For example, the image below shows a simulation of a sprayer aimed at the inner surface of a side window. This allows engineers to analyze water flow paths, assess the risk of ingress, and refine the structural design accordingly.

In addition, PreonLab can simulation flow conditions on different hydrophobic surfaces, reflect different contact angles of liquid droplets on the surface, predict the contact time between the surface and the water flow, and better evaluate the hydrophobic performance of the interior.

The animated figure below shows three surfaces with the same length and slope. However, due to different contact angles of the liquid droplets on the solid surface, the time it takes for them to flow across each surface varies.

The mesh-free simulation software PreonLab delivers precise results for splash scenarios, offering essential data like wet surface area and contact time. This empowers engineers to optimize water flow paths and hydrophobic surfaces more efficiently, reducing dependence on costly physical testing. As a result, PreonLab is rapidly becoming a vital tool for innovation in smart cockpit liquid protection.

Stay tuned

Don't miss the Simulation blog series. Sign up today and stay informed!

Read More About This Topic

Stay tuned for the Simulation Blog

Don't miss the Simulation blog series. Sign up today and stay informed!

Technical Support Engineer at AVL List Technical Center (Shanghai)