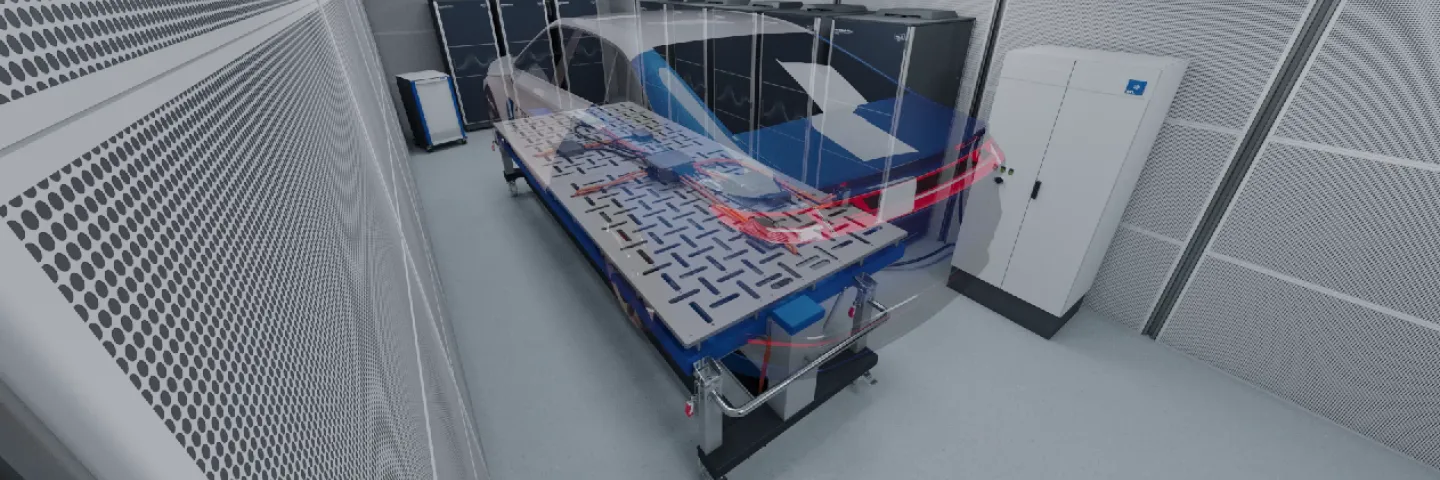

AVL Copper Car™ is a test system for electrical system integration and software regression testing. The benefits of the system are evident from product validation to end-of-life. The core element of the test system is the chassis replicator. The system-under-test (SUT) setup consists of vehicle electrical system components along with the original wiring harness.

This chassis replicator enables a setup that is comparable to that of the vehicle on the road. The system is complemented by electric motor and battery emulators that significantly accelerate test speed and increase test coverage.

Driving and Charging

The electric system is highly interconnected. OEMs must guarantee in development and during usage that all components are safe and react in the expected way. With our Copper Car™ test system, you can use one Copper Car™ Chassis Replicator per vehicle variant during the vehicles lifetime to run test cases like „car open“, „car start“, „car charging“ to test all involved components and software.

Software Updates

End users desire safe and reliable vehicles that simply work. Software updates are becoming more frequent and OEMs need to ensure that they are delivered in a timely and discrete manner to the user. With Copper Car, an OEM can use one Copper Car Chassis™ Replicator per vehicle variant throughout the life of the vehicle to test upcoming updates in real time.

The Chassis Replicator is engineered to optimize the vehicle-like system under test (SUT) setup, ensuring unparalleled accuracy and reliability. It facilitates the precise representation of the original wiring harness, mirroring the conditions of a vehicle on the road - with similar galvanic and electromagnetic properties like the real vehicle chassis.

The Chassis Replicator is designed to support a wide range of testing scenarios, providing a robust platform for evaluating the performance and integrity of electrical systems and software. Whether you're testing new components or validating existing ones, our Chassis Replicator ensures that your tests are conducted under realistic conditions, delivering trusted results.

- Accurate Representation: With similar galvanic and electromagnetic properties like the real vehicle chassis.

- Realistic Materials and Dimensions: Uses materials and dimensions based on actual vehicle chassis for authenticity.

- Optimized SUT Setup: Enhances the setup process for vehicle-like testing environments.

- Comprehensive Testing: Supports a wide range of electrical and software testing scenarios.

Experience the future of vehicle testing with our Chassis Replicator, where precision meets reliability.

AVL Emulators provide a cutting-edge solution for emulating electrical motors, batteries, and chargers enabling comprehensive testing of power electronics without the need for mechanical or electrochemical setups. This versatile tool supports all development phases, by using software models to replicate the behavior of e-motors and batteries.

- Accurate Dynamic Control: Ensures precise testing with correct dynamics.

- Efficient Full-Load Testing: Facilitates time-efficient full-load production testing programs.

- Comprehensive Testing Solution: One tool meets all testing requirements.

- Concurrent Engineering: Enables parallelization of tasks and independence from e-motor and battery constraints.

- Immediate Full Power Testing: Provides full voltage, current, and power from the first day of testing, eliminating the need for signal-level setups.

- Original Hardware and Software Compatibility: Tests with original hardware and software setups without requiring inverter modifications or modeling efforts.

- Real Power Drive Cycle Analysis: Investigates motor tolerances at real power drive cycles.

In the future, every OEM will have at least one Copper Car to replicate the electrical propulsion system for each vehicle variant throughout the vehicle's lifetime.

– Horst Hammerer, Director Electric System Testing, AVL List GmbH

Copper Car™ provides unparalleled precision in electrical replication, ensuring accurate and reliable results. Rivaling and often surpassing Signal HiL testing speeds, our fully automated system focuses on the electrical system level and software. Utilizing real units, software, cable harnesses and chassis replicators, we provide comprehensive testing solutions that meet the highest standards of quality and efficiency.

- Highest test coverage, test efficiency and testing speed.

- Reduced number of vehicle prototypes.

- Lifecycle coverage: From development to end-of-service.

The inverter is very complex, and its behavior and handling influence the driving experience significantly. It needs to be tested and developed without further influences of other components. Learn more about our test system (TS) for inverter.

Flexible test automation solutions for virtual and real-world environments

AVL RACETECH, the motorsport department of AVL, presents the prototype of an innovative H2 internal combustion engine. The power unit is a compact, hydrogen-powered 2-liter turbo engine, with intelligent water injection, which achieves a totally new performance level. The first racing engine that AVL RACETECH is developing and building in-house.