When developing transmissions, it is necessary to factor in efficiency, drivability, weight, comfort, and costs at all times. For example, overcoming the conflict between efficiency and excellent NVH behavior in the best possible way requires comprehensive understanding of the mutual influence of the determining parameters. Expanding the parameter space to include the related systems, e-motor, and pulse-controlled inverter quickly makes it impossible for developers to have an overview of the range of parameters and to fine-tune the system optimally. All of these systems have a significant NVH influence on the overall system. In our R&D program at AVL, we acquire the necessary in-depth knowledge of components and systems, as well as of the methodology for developing the ideal solution. We are constantly refining approaches through application in customer projects.

Expanding Expertise

Staying one step ahead of the competition at all times means acquiring the relevant expertise. At AVL, we meet this challenge through:

- our excellent team of innovative developers

- constant exchange

- the continuously changing requirements of our customers

- the strategic support of our research and development activities

Integrating New Methods

New transmission systems, and the further optimization of existing systems, require development methods that can be continuously adapted to the multitude of changing requirements. Methods for optimizing design, testing, software development, and application, as well as for NVH, efficiency, costs, and manufacturing tolerances need to be integrated into existing processes as quickly as possible.

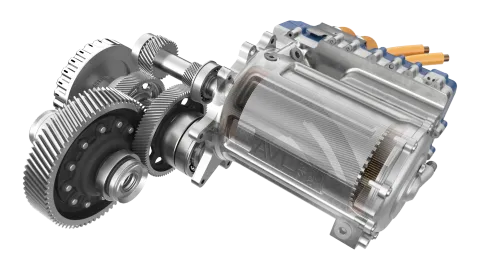

As an independent development service provider, we offer cutting-edge technology for all types of transmissions. We support OEMs and suppliers in building knowledge, adapting to new methods, and developing individual components such as e-motors and inverters. We support newcomers with complete solutions when entering the market.

Throughout development, you benefit from the latest methods and processes: from defining target values and creating the concept, through designing the individual components, simulation, design approval, and validation, to complete series programs. Our strengths include certification-compliant software development and the application of end use.

Thanks to many years of experience, engineering expertise, and efficient test and simulation tools, we are able to provide our customers with optimal support in the development process. The central philosophy of our modular solutions is scalability in terms of performance.

Comprehensive Portfolio

We have in-depth knowledge in all key areas under one roof. AVL offers development services for passenger cars, trucks, off-road vehicles, and stationary applications. We have all the necessary expertise to successfully develop a product for series production, or to provide support in subareas. Areas covered include:

- Concept and basic layout

- Design

- Simulation

- Testing

- Software development

- Application

Global Network

More than 800 employees in 15 subsidiaries worldwide are on hand to provide you with the best possible local support. Our competence centers are located in Graz and Regensburg. A very strong transmission engineering team is also on site in Sweden, Italy, France, Spain, Great Britain, India, China, and Japan. Our subsidiary in Budapest focuses on areas such as design, simulation, and testing on the testbed or in the vehicle at our test track in Zalaegerszeg.

Optimal Methods

You benefit from the latest development methods, which we are continuously developing and optimizing in line with current and future market and customer requirements.

Maximum Test Scope

We provide component and system test environments that meet current and future market requirements. Alternatively, we can also develop customized versions of these test systems – depending on your specific needs. We cover both component and development tests, as well as endurance tests.

Own Research and Development

We consciously invest a portion of our turnover in our extensive in-house R&D, which allows us to continue to develop our technological competence. You can rely on solid system expertise and advanced methods at all times.

Training

We are happy to hold training courses for your employees to share our accumulated knowledge.

Target Fulfillment

After defining the application requirements, we break them down into components and design. After extensive testing and verification of the goals, we bring everything together in the overall system, or in the implementation of software functions. Consistent requirements management is a key element in being able to develop a product in a targeted manner.

Short Time to Market

Our own simulation and development methodology allows us to visualize the product in our simulation environments very early on in the development process. In doing so, we increase the level of maturity at an early stage. This enables you to achieve your goals faster, while also saving costs.

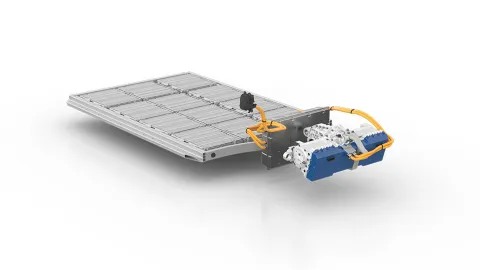

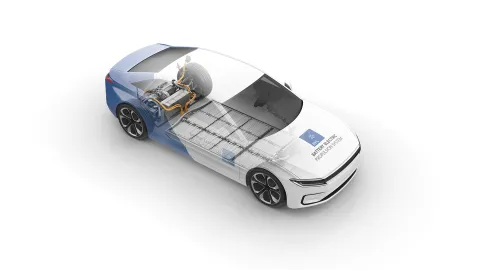

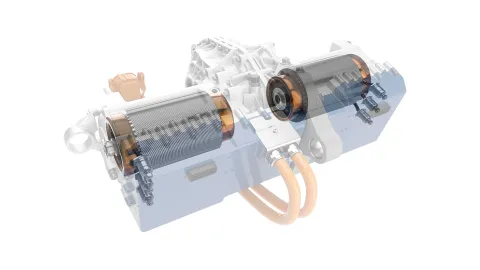

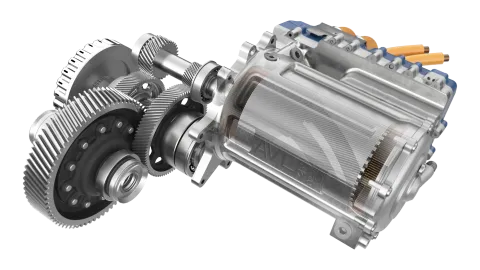

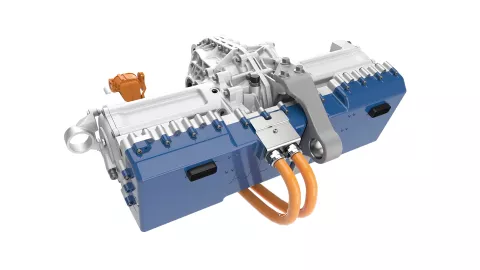

Modular Solutions

We create a modular system for you that you can use in a variety of ways and scale in terms of performance. You can also visualize different types, e.g. 1-E motor or 2-E motor drive solutions for the e-axle, taking into account maximizing the use of identical parts. We provide you with the complete software from a single source.

Cost Optimization

We offer a product that is designed to be robust against production fluctuations. Our simulation methods allow tolerance requirements to be expanded. This lowers the costs of the individual components and the overall system

We want to advance the automotive industry with our electric driveline and transmission solutions. In doing so, we utilize all technological options to ensure sustainable mobility.

– Wilhelm Vallant, Product Manager for Electric Driveline Systems & Transmissions, AVL

Related Topics

We are constantly working on new solutions. The following might be interesting for you: