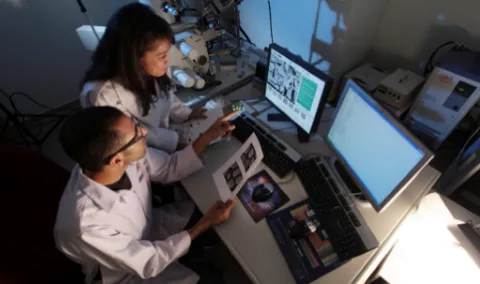

High Precision Mechanical Design

We offer a deep understanding of the complexities involved in design and assembly of high-precision systems where mechanical performance, thermal stability, and manufacturability must be perfectly aligned. Our expertise lies in solving challenges necessary for achieving highly precise and repeatable positioning of components, ensuring stress- and deformation-free fastening of subcomponents and additionally minimizing thermal deformation during the operation of highly sensitive systems to prevent drift and distortion.

Services:

- Mechanical Concept Design

- System Integration

- Cleanroom- and Vacuum-Specific Engineering

- Bearing System Design and Optimization

Simulation / Numerical Analysis

Our computational engineering team provides comprehensive simulation in fluid and solid domains, addressing thermal, mechanical, and acoustic phenomena. We are specialized in predicting and mitigating pressure pulsations, flow-induced vibrations, thermal drift, and structural deformation down to the nanometer scale — ensuring reliable and efficient system performance from early concept to field validation. Benefit from our methodology that combines fast-running 0D/1D system-level simulations with detailed 3D analyses — enabling early detection of vibration, noise, and thermal/mechanical performance issues.

Services

- System-Level Fluid & Acoustic Simulation

- CFD-Based Flow & Multiphase Simulation (incl. Flow-Induced Vibration)

- Thermal & Thermomechanical Simulation

- Structural & Material Behavior Simulation (Simulation of hyper-/ visco- elastic Materials (e.g. rubber components))

Acoustics and Vibration

At the micron scale, even the smallest vibration can blur features, cause pattern errors, and reduce yield. To guarantee reproducibility and consistent quality, disturbances must be minimized to the absolute limit. The AVL Precision Engineering Team provides end-to-end solutions for vibration suppression and waterline acoustic optimization — ensuring your most sensitive systems perform with accuracy and stability. Our highly specialized 0D/1D duct acoustics team helps you predict and mitigate pressure, flow, and force oscillations in fluid-filled piping systems. Through advanced modeling and system-level analysis, we detect potential vibration, noise, and performance issues early in the development process.

Services

Fluid and Solid Vibration Evaluation/Mitigation

- Modal Analysis & Experimental Vibration Testing

- Active Vibration Control/Silencer Development

- Micro-Vibration Analysis (Flow-Induced Vibration)

- 0D/1D Acoustic Analysis of Flow, Pressure & Force Fluctuations

- Flow-Induced Vibrations (FIV) & Filling Assessment

Industrialization

We empower our customers to transform prototypes into scalable, cost-efficient series products. Our industrialization expertise ensures a seamless journey from design for manufacturing and cleanroom-compliant processes to a smooth ramp-up from pilot builds to stable volume production. Leveraging deep expertise in production and quality engineering, along with tailor-made tooling and test equipment, we deliver robust manufacturing at the highest level of precision. Sustainability and lifecycle engineering are embedded in every step, enabling resource-efficient and future-proof production solutions.

Services:

- Design for Manufacturing & Assembly

- Comprehensive Planning & Risk Management

- Production & Quality Engineering

- Production Process Development / Series Transition

- Supplier Management & Qualification

Software, AI and Data Intelligence

AVL delivers end-to-end hardware and software development from the initial concept to serial production. Our expertise spans embedded systems, intelligent controls, connectivity, data intelligence, AI, and predictive maintenance. With advanced simulation, testing & validation, as well as safety and EMC engineering, we ensure the highest level of reliability. Together with professional supplier management and FMEA, we create efficient, robust, and future-proof systems that enable breakthrough technologies for a variety of electrical components.

Services

- Electronic Hardware Development

- Development of Firmware & Application Software

- Software Testing & Validation

- Supplier Management

- EMC Simulation

- Data Intelligence & AI

- Safety & Security

- Development Methodology and Failure Mode & Effects Analysis (FMEA)

Material Technology / Reliability

Challenging boundary conditions such as absolute form stability, vacuum or high-energy radiation require advanced materials. We support material selection by balancing thermal conductivity, corrosion resistance, and dynamic load requirements. Through tailored test scenarios, we assess suitability, identify risks, and define safeguarding measures. Combining in-house testing, strong partner collaboration, and deep expertise in result interpretation, we deliver reliable design insights, approvals, and a release process seamlessly aligned with your product development.

Services

- Material Requirements Specification

- Material Selection

- Advanced Material Testing and Predictive Modeling

- Material Failure Analysis & Reliability

Developing high end solutions requires a unique combination of disciplines — that is not always fully available in-house. This is where AVL make the difference. Partnering with AVL means gaining more than an engineering service — it means securing a strategic ally who accelerates innovation, reduces risk, and protects your competitive advantage.

You need expertise you don’t have in-house for a special challenge?

We give you direct access to specialized know-how across mechanics, electronics, software, and system integration, enabling solutions tailored to your exact needs.

We bridge your capacity gaps with precision expertise.

We offer cost efficiency through flexible resource balancing, allowing you to scale capabilities without the expense of building them in-house. Our proven processes, experienced teams, and advanced tools shorten development cycles, helping you bring products to market faster.

We provide the tools, you provide the task.

Our interdisciplinary approach combines several disciplines in-house. We bring software licenses, compute clusters and high specialized simulation engineers.

Dr.-Ing. Valerius Boxberger

Project Manager Specialized

AVL List GmbH, founded in 1948 in Graz, Austria, is a global leader in the development, simulation, and testing of mobility technologies, employing 12,000 people and operating more than 50 tech and engineering centers worldwide.

The Precision Engineering department was established eight years ago in AVL’s Großmehring site near Ingolstadt, Germany. Today, a team of 50+ experts develops highly sensitive precision systems. Customers appreciate AVL’s reliability, security, and seamless access to cutting-edge expertise and facilities — all delivered by a single, trusted partner.

8+ Years of expierence

50+ Experts for Precision Engineering

50+ Executed Projects

500+ Engineers from various technical department, ready to support

"In today’s precision engineering industry, where technologies grow ever more complex and tolerances ever tighter, partnering with an experienced development service provider ensures faster innovation cycles, reduced risk, and reliable access to cutting-edge expertise across the entire value chain."

Valerius Boxberger, Project Manager Specialized