Many global regulations are forcing ships and vessels to continually reduce emissions. This shift is driven by the need to combat climate change and protect oceans. Our goal is to manage the transition to a sustainable future with proven technologies and help to achieve best efficiency with testing solutions. By leveraging advanced battery, inverter, and alternative fuel ICE technologies, harmful emissions can be significantly reduced. Our comprehensive test solutions ensure propulsion systems are effective, reliable, and safe for long-term use.

Using existing know-how and technologies of the automotive industry, and applying them in maritime applications is the way to go forward. Our solutions are cut out for your challenges.”

– Sascha Heinecke, Director Sales, Industry Solutions

We address various customer groups to provide a holistic approach: Vessel owners, charterers, builders, naval architects, constructors and integrators. Engine and parts manufacturers, tier 01 and tier 02. Universities, R&D institutes and shipyards as well. Our solutions can be applied to vessel classes such as: Pleasure craft, speed boat, ferry, tug-boat, yachts and cargo ships to some extent.

Our comprehensive battery testing offering includes test systems for both high-voltage battery cells and battery packs. These solutions come with cell or pack cyclers, precision measurement equipment, thermal chambers, integrated safety systems, and fully automated software with robust data management capabilities. Thanks to our deep expertise in battery technology, our systems provide an ideal platform for thorough battery testing and validation.

In modern energy applications, on ship and on shore, optimizing energy efficiency and system performance is crucial. Our integrated systems leverage advanced SiC technologies to transform energy from various sources into reliable power – to enhance and streamline the operation of electrical power and energy systems. We enable our customers with the ability to optimize power performance along the energy flow from the power source to efficient energy applications.

Developing e-motors with high power density and efficiency is crucial for modern propulsion systems. It is equally important to achieve maximum passenger comfort and operational economics. Our e-motor test systems are designed to unlock the full potential of e-propulsion systems. Moreover, issues in terms of noise, vibration, and harshness (NVH) need to be addressed with dedicated test solutions. These systems are built to achieve fast and reliable test results while also keeping own noise patterns at a minimum.

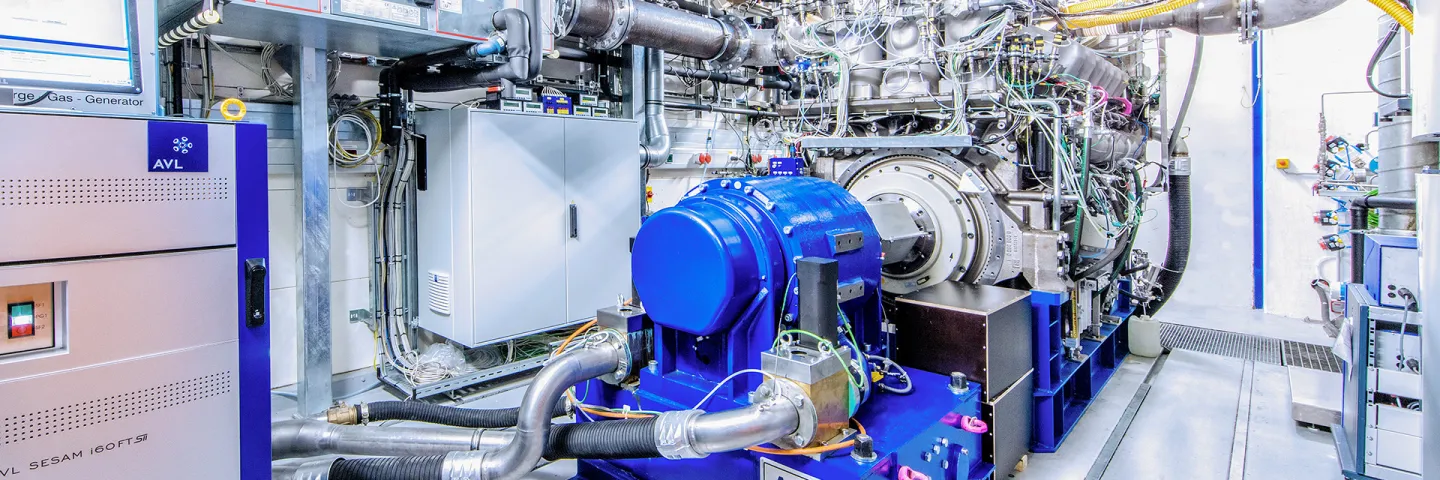

Our hybrid and engine test systems are highly flexible development environments. These test systems provide precise test and measurement systems with high reproducibility for testing internal combustion engines and their hybrid components. For hybrid engine development, the systems use battery emulators to act as electric power sources or sinks, ensuring highly realistic battery behavior emulation on the testbed. Dedicated fuel supply installations, including conditioning and consumption measurement, support multi-fuel testbed operation.

We are at the forefront of innovative mobility solutions, specializing in hydrogen engines, hybrid powertrains, battery-electric systems, and fuel cell technologies. With deep expertise in propulsion functions, subsystems, and components, we are uniquely positioned to support seamless system integration for the marine industry. In addition to our engineering capabilities, we offer strategic technology consulting to help you stay ahead.

AVL E-Mobility Testing Solutions – Brochure

From battery to full vehicle, from products, to test systems to whole test facilites – learn how we can support your testing needs.

Brochure – Marine Propulsion Testing

Navigating the future. Test solutions for ships and vessels.

Solution Sheet – Battery Testing for Ships and Vessels

Dedicated test solutions for high-voltage battery systems.

AVL’s comprehensive worldwide network of experts allows best customer vicinity, ensuring consistent and connecting testing fields globally. Wherever your R&D challenges take you, we are always close at hand, ready to provide the service you need.

> 70

years of experience.

> 5,000

employees worldwide for testing solutions.

> 30

countries covered by the global network.

> 7,000

testbeds installed worldwide.

> 80

turnkey projects realized.