As a leading provider of testing equipment and high-tech engineering services, we specialize in single components, powertrains, and complete propulsion systems. Our innovative, user-oriented solutions are tailored to the specific needs of our customers' units under test (UUT).

We are committed to meeting the strict acoustic standards required in modern NVH testing, ensuring that all systems meet agreed-upon NVH targets. Each component is carefully tuned, and the entire system is validated through a comprehensive acceptance analysis, guaranteeing optimal performance.

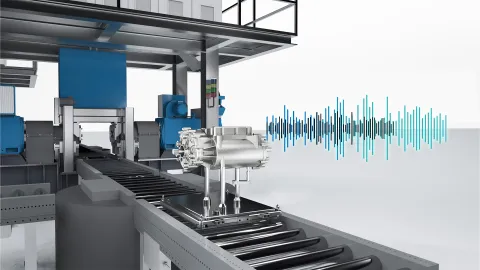

Our advanced NVH test systems are designed to support all UUT variants, enabling precise validation of e-motors. We provide highly efficient, fast, and sustainable solutions to tackle NVH challenges, ensuring optimal testing conditions for reliable results.

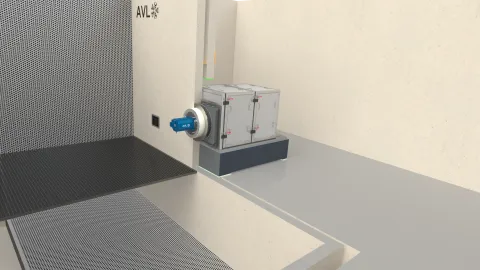

A key advantage is the specially engineered load unit and acoustic chamber, which allow for ultra-low noise measurements even at high speeds. This minimizes interference with the acoustic free-field conditions of the laboratory, ensuring highly accurate data. Additionally, our test facility offers seamless integration into existing infrastructures and is available as a flexible, mobile containerized solution.

Key Features:

- Ultra-Silent Design: Achieve minimal overall noise levels in the test cell, with noise as low as 50 dBA at 20,000 rpm, ensuring precise and quiet testing conditions.

- Containerized Solution: Our fully assembled, pre-commissioned testbed comes ready for immediate use, significantly reducing onsite setup activities and ensuring a faster, more efficient deployment process.

Highly Customizable

Standard and highly customizable testing solutions from single components to full vehicles.

Guaranteed Noise Limits

Guaranteed NVH behavior through optimal NVH design.

Minimal Footprint

Lowest acoustic impact due to minimal footprint.

Full Performance

Uncompromised power, torque, and speed performance combined with seamless integration into AVL‘s toolchain.

Our AVL E-Motor TS™ NVH system allows manufacturers to precisely assess and optimize noise, vibration, and harshness in electric motors. It ensures that electric drivetrains deliver superior comfort and performance, and supports the evolution of e-mobility with innovative testing technology.”

– Asmir Hrnic, Global Product Manager, AVL List GmbH

AVL E-Mobility Testing Solutions – Brochure

From battery to full vehicle, from products, to test systems to whole test facilites – learn how we can support your testing needs.

AVL NVH Test Systems – Brochure

Our commitment to silence.

Whitepaper – NVH Test Systems for E-Motors and E-Axles

Learn more about our NVH test systems for e-motors and e-axles.

AVL E-Motor TS™ NVH – Solution Sheet

Our commitment to silence.

Success Story – “NVH Testing for KTM”

Ready to race – meeting ultimate acoustic requirements.