In comparison to reciprocating piston engines, rotary piston engines offer a higher power to weight ratio, are easier to install in small spaces and operate with almost no vibration. This makes them the preferred solution for applications that benefit from precisely these advantages.

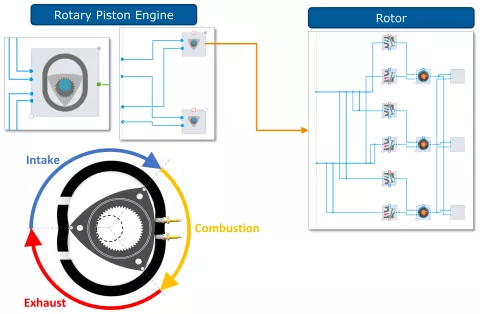

This version of AVL CRUISE™ M offers a dedicated rotary piston engine component. You can pull it from the component library into the workspace. Different injection types (direct or external) are offered. CRUISE M automatically creates a macro element that holds rotor components which themselves are built from basic blocks for combustion chambers, intake and exhaust ports, leakage flows and injectors.

The full set of combustion and pollutant formation models known from the reciprocating piston engine can also be applied to the rotary piston engine.

An installation example is provided to help you get started with your rotary piston engine project.

The Engineering Enhanced Cylinder components and Wizards for gasoline and diesel engines have been enhanced with several functionalities:

- Diesel Wizard: The wizard now takes into account the fuel density as specified in the fuel properties file. This refinement is added to existing considerations of fuel properties like lower heating value, stoichiometric air to fuel ratio and fuel composition from H, C and O atoms. Furthermore, the wizard has been improved to more accurately incorporate the conditions upstream of the combustion chamber when Exhaust Gas Recirculation (EGR) is present. The composition of species and excess air ratio, given as a mixture of fresh air and recirculated exhaust gas, are now calculated in the exact same way as they occur when a full air path is modeled. The performance of the wizard has been improved by allowing more iterations during its optimization procedure.

- Gasoline Cylinder: The cylinder model has been enhanced with additional parameters to offset the individual combustion submodels. This ensures further flexibility during the parametrization process of SI combustion. The combined threshold to distinguish between the low and high load parts of the wall heat and the high-pressure IMEP models are now split into two separate parameters. This allows the threshold to be specified individually for each of the models, facilitating a more straightforward parametrization of the combustion. Furthermore, adaptations of the combustion models have been implemented, to represent state-of-the-art engines even more accurately.

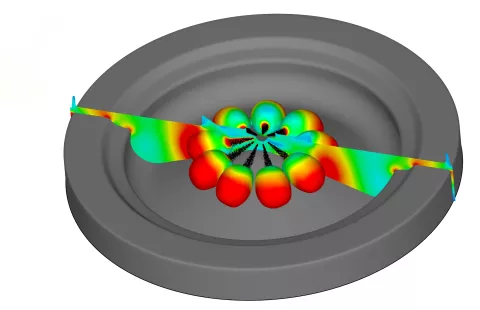

To support efforts to reduce greenhouse gas emissions, the use of hydrocarbon-free fuels is being discussed. The first engines powered by hydrogen or ammonia are already being used in trucks and ships. Depending on the fuel type and engine/vehicle application, spark plugs or diesel injection are used to ignite the fuel.

After spark-ignited hydrogen (and ammonia) engines can already be simulated with the status of the ECFM-3Z model in 2023 R1, the model has been expanded again to be able now to simulate diesel-ignited variants with 2023 R2.

Using the new ECFM-3Z model allows to perform these simulations more efficiently compared to solving the typically large hydrocarbon reaction schemes by deploying the GGPR module.

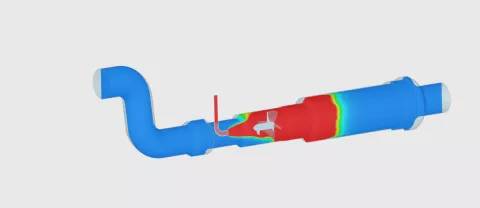

Heterogeneous surface reaction modelling capabilities are needed to compute the conversion of species in exhaust gas aftertreatment components of ICE-based powertrains. In addition to that, these capabilities are nowadays also required for fuel cell and fuel reformer simulations. With 2023 R2, the heterogeneous surface reaction module is available in AVL FIRE™ M, ready for use in the above mentioned applications. In addition to making the module available, it has been extended compared to the status known from AVL FIRE™ Classic, for compatibility with the User Coding Interface (UCI) of CRUISE M. UCI allows to conveniently define and use arbitrary user-tailored reaction schemes and transfer model.

With this new release of FIRE M, the General Gas Phase Reaction (GGPR) model along with activated Species Transport can be used with the Eulerian Multiphase models, both the Multi-fluid and the Volume-of-fluid model. This allows, for example, to model the decomposition of urea through the thermolysis-hydrolysis process using the "Urea Thermolysis" mass exchange model in the multiphase framework.