Release 2022 R2 of AVL CRUISE™ M makes the electrochemical simulation of batteries easier and more accurate. For this purpose, two major enhancements have been made.

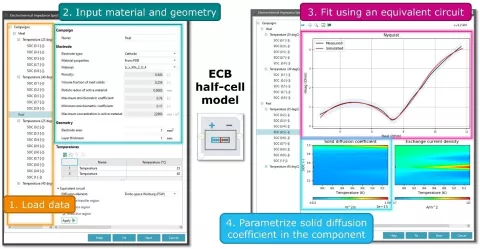

CRUISE M now provides you with a tailored EIS Parameterization Wizard that simplifies the process of finding the electrode diffusion coefficient based on measured data. The “find the equivalent circuit” option starts the automatic search for the best fitting approach.

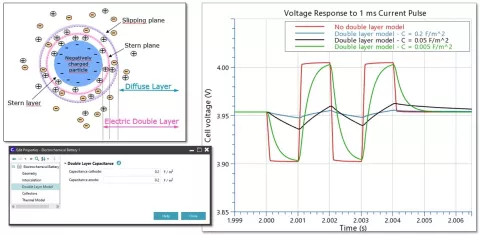

Double layer effects are now considered. The double layer induces an electrical field that is capable of storing and releasing charge in much less time than the intercalation process of lithium ions, like in a capacitor. Such high frequency responses are covered as part of the existing electrochemical battery at four different positions. First, at the electrode-electrolyte interface of the cathode and anode, and second, at the interfaces between the current collector plates and the adjacent electrodes.

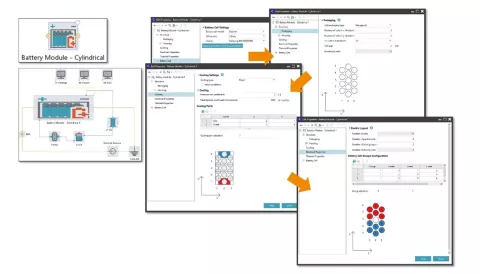

The module “component cylindrical cell” is the extension to the prismatic and pouch cells that are already available.

It allows you to define the cell arrangement, the housing configuration, the cooling type, the electrical connection pattern and all types of connection ports, as well at the measuring points for interaction with other components. The cells are modeled in 2D featuring different temperatures in radial direction and across their height. It supports both equivalent circuit models and Batemo cell models.

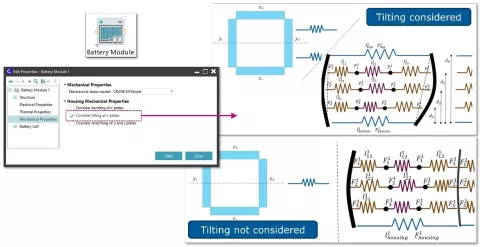

Pouch cells are usually connected to the bottom of the enclosure via a thermal paste. The fact that cells are fixed at the bottom and the other sides are more flexible to move also impacts the expansion/contraction of cells and the mechanical stresses that build up. This version of CRUISE M offers the possibility to model cell tilting.

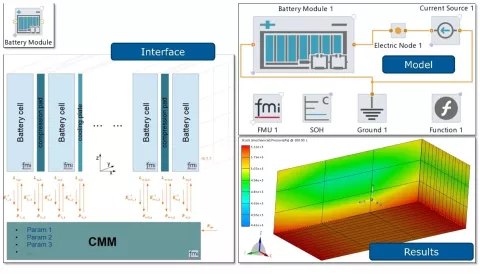

A new interface is available should you need to integrate custom model extension into existing CRUISE M models. The interface allows you to integrate your user-defined sub model without having to sacrifice the comfort of the overall solution.

The Battery-Module has been extended by a dedicated interface for mechanical models. This allows the custom models to describe all mechanical aspects of the module's housing that react to expanding and contracting battery cells.

The model needs to be given as FMU complying to a dedicated interface specification defined by CRUISE M.

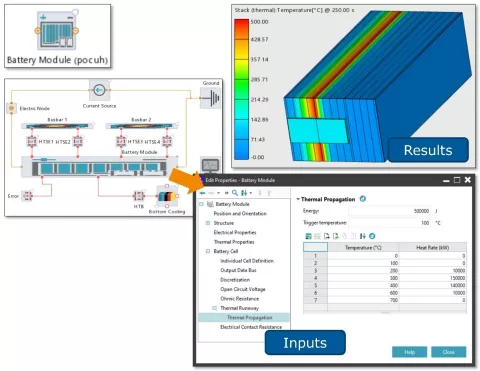

Easy simulation of battery thermal behavior in the event of thermal runaway.

Another new feature of the Battery Module component allows you to study the propagation of heat through a module assembled from cells, cooling plates, and pressure pads. The input is the heat released by the cell during thermal runaway. You can determine this information using abuse tests on a single cell and the Compose app. Together with the actual cell energy and a trigger temperature, this input is sufficient to model the thermal history of a single cell. You can view the local temperature rise in a cell and the spillover to neighboring cells, as well as the propagation across the entire module.

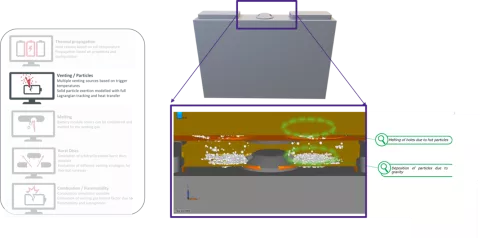

AVL FIRE™ M is now able to simulate the exertion of solid particles during battery cell venting. The particles are modelled using a Lagrangian description of particle motion. Coupling of energy, momentum and turbulence exchange with the surrounding gas phase is taken into account. Specific sub models are used for the drag law and evaporation.

Methodology development has shown that consideration of these particles can provide additional insights into the occurring risks posed by particles, as shown in Figure 7.