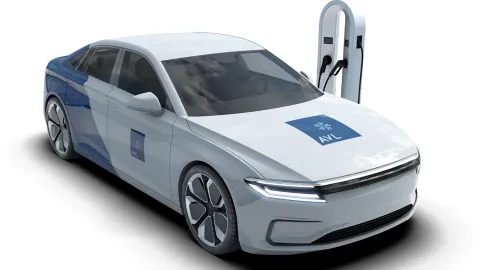

Conventional propulsion systems and the infrastructure are only loosely connected, while plug-in electrified vehicles are strongly connected to the infrastructure. New standards and norms regarding connections, communication, safety, etc. had to be established between OEMs and the industry in recent years. It is desirable to move charging test activities to a controlled test environment to reduce test costs, accelerate development, improve V&V, and enhance quality and customer experience.

Simulated charging enables testing of various communication protocols as well as misuse or failures/malfunctions of charging stations. For AC charging, different mains supplies can be tested depending on the region, e.g. JP, US and EU.

Complying With Current and Future Standards

DC: CCS1, CCS2, CHAdeMO, GB/T, NACS | AC: Type 1, Type 2, GB/T, NACS | In future: ChaoJi, MCS.

Performance Testing

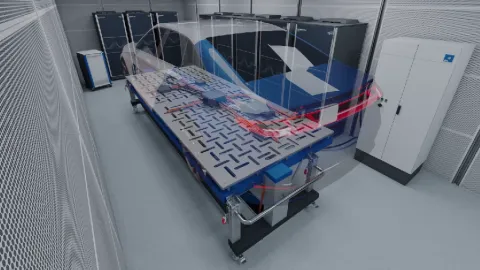

Validation on system level during high-power charging.

Communication Testing

Focus on communication manipulation and failure emulation with extended edge-testing.

Covering User Expectations

Targeting the need for conformity and interoperability.

Reducing Testing Operation Efforts

Bi-directional charging and emulated disconnect of charging plug with AVL‘s automation system integration.

To ensure robust, standards-compliant charging communication, reliable testing solutions have become essential for both vehicle and infrastructure manufacturers. The central component of the Test System is the AVL Universal Charger™. It plays a crucial role in evaluating charging communication performance and ensuring the accuracy and reliability of test results and designed to provide comprehensive interoperability and conformance testing for electric vehicle charging systems.

The system validates charging communication across all major global standards by simulating faults, injecting errors, and manipulating polarity to observe and assess system response under varied conditions. This enables all kind of electric vehicles to meet the highest levels of reliability and performance.

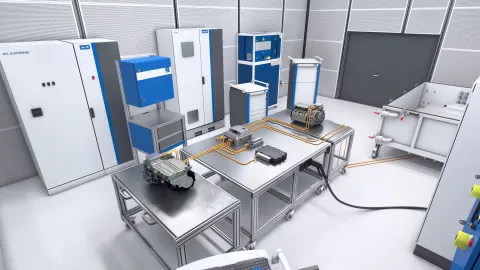

To support these testing capabilities, the Vehicle Charging TS™ integrates the AVL Universal Charger™ with an AVL DC Source, an optional AC Grid Emulator, and the AVL Test Automation System. Together, these components deliver precise, repeatable, and high-performance testing environments that help accelerate development, verify compliance, and ensure dependable operation in real-world charging scenarios.

| DC Charging | |||

| CCS Type 1 | 500 A | 1,000 VDC | 800 kW |

| CCS Type 2 | 500 A | 1,000 VDC | 800 kW |

| NACS | 800 A | 1,000 VDC | 800 kW |

| CHAdeMO | 200 A | 1,000 VDC | 200 kW |

| GB/T | 250 A | 1,000 VDC | 250 kW |

| AC Charging | |||

| Type 1 | 32 A | 7.4 kW | |

| Type 2 | 32 A | 22 kW | |

| GB/T | 32 A | 22 kW | |

| NACS | 80 A | 19.2 kW | |

Easy to Integrate

Seamless integration into existing AVL testbeds to upgrade to e-mobility testing environment.

Ensure Vehicle Mobility

Priorizing quality and charging process realize a safe, reliable, successful charging process.

High-Power Charging and Testing

Meet the global trend of shortening charging times.

Optimized Operations

Increase automized functional testing to reduce after-sales costs.

Communication Test

The communication between charging station and vehicle can be analyzed and tested. If necessary, the communication can be influenced or the reaction can be checked if a problem occurs during the charging process.

High Power and Bi-Directional Charging

Our powerful AVL E-STORAGE not only enables supply over the entire range (voltage, current, power) of charging applications, but is also prepared for the increasingly important bidirectional testing.

AC Emulation

The optional use of a power supply emulator makes it possible to test different power supplies by region, e.g. JP, US and EU. With this tool it is also possible to emulate phase failures and frequency fluctuations.

Highly Automatable

Specific load test packages can be executed automatically with the test system. It is also possible to simulate the plugging process of the charging connector.

Accelerate your EV charging development cycles with smart, automated testing — combining speed, precision, and flexibility to meet today’s demands and tomorrow’s standards with confidence.”

– Harald Mahringer, Global Product Manager, AVL List GmbH

AVL E-Mobility Testing Solutions – Brochure

From battery to full vehicle, from products, to test systems to whole test facilites – learn how we can support your testing needs.

AVL Vehicle Charging TS™ – Solution Sheet

Fast development and validation of electric drives.

AVL Universal Charger™ - Solution Sheet

Find out more on the capabilities of the Universal Charger - from component validation to communication testing and beyond.