SOFC is a new and growing technology which has tremendous potential in the energy and power generation sector and industrial testing solutions are not widely available yet. As the market for SOFC based-products rises, there will be a need for industrial quality test beds and measurement devices which not only allow extensive testing but also provide tools for data and performance analysis. Robust testing enables the development of better products which will accelerate the uptake of high efficiency energy generators based on SOFC technology.

Performance testing

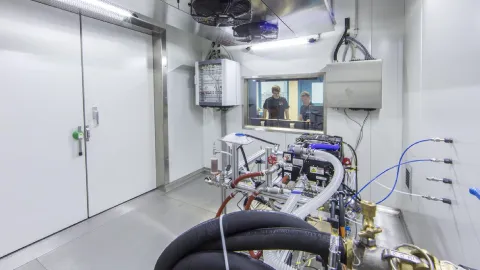

The system test bed allows complete performance analysis of the system under all operating conditions – from mild to severe.

Environmental testing

Extensive environmental testing with the system test bed will allow the product to be deployed worldwide, increasing market penetrability.

Testing with gas mixtures or gas blends

The system test bed is equipped to operate with hydrogen, methane and mixtures of hydrogen and methane. The test bed can also supply a range of other gaseous and liquid fuels.

Emulation of different operating scenarios

The system test bed also allows emulation of different operating scenarios and environments that the SOFC system/product might face.

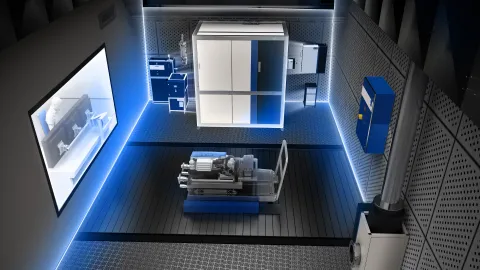

The SOFC system test bed is specifically meant for testing units/systems between 5 and 400 kWe net power and can be configured for both DC and AC output applications. Depending on the size of the unit under test, the system test bed is classified as ULD (Ultra Light Duty) for 5-50 kWe, LD (Light Duty) for 50-160 kWe and HD (Heavy Duty) for 160-400 kWe.

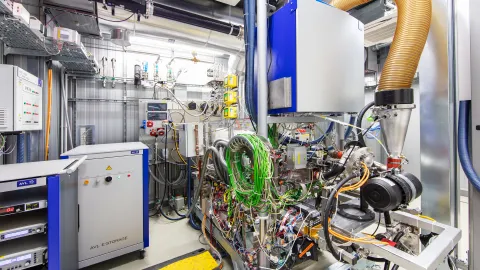

- Fuel supply measurement & control – Currently solutions are available for hydrogen, natural gas (or methane) and methanol. The modules used are AVL Hytron™, AVL Gastron™ and AVL 735S™. They provide accurate flow and pressure control along with measurement.

- Exhaust conditioning – The exhaust module is an active exhaust module with capability for water knock-off and is ATEX certified. This ensures that exhaust from the unit under test is safely vented out.

- Test bed automation – A powerful and versatile test bed automation called PUMA 2™ Fuel Cell will help in setting up all kinds of test regimes and helps in protecting both the unit under test and test bed hardware from damages in unlikely events.

- Bi-directional DC load – This comes in a range of sizes, with different current and voltage ratings. The same hardware can also be used for both fuel cell and electrolysis testing.

- AVL climatic chamber – This allows the emulating different environmental conditions for the unit under test. Climatic chambers can be offered in a wide variety of sizes

- AVL thermal integrator – To accurately measure and quantify residual heat coming from the exhaust.

- AVL emission species analyser – When it comes to multi-fuel testing, emission species analysis is key and the test bed comes with this optional feature.

- Test bed safety – The entire test bed is equipped with safety features to protect the unit under test, the test bed equipment and the test bed facility, giving you the customer absolute peace of mind.

| Property | Unit |

|

Flow measurements for hydrogen, natural gas, methanol |

H2 – up to 50 kg/h Natural gas – up to 280 kg/h Methanol – up to 125 kg/h |

| Flow pressure control to unit under test for hydrogen, natural gas | H2 & CNG – up to 55 bar |

| Bi-directional DC load | Up to 500 kW with different voltage & current options |

| Emission species analyser | For a range of species such as CO, CO2, SO2, H2, NO2 |

| Exhaust heat quantification | Via calorimetric measurement |

| Test Bed Safety | State of the art Gen 3 test bed safety system |

The SOFC system test bed is one of its kind industrial test bed that allows you to bring innovative systems to the market faster thanks to enhanced system testing.

SOFC specific test bed

Designed with the experience of SOFC developers and test engineers. With every testbed you additionally benefit from AVL’s development know-how and testing methodology expertise.

Maximise R&D capability

Increase and maximise your R&D potential with a sophisticated and high-class system test bed.

Wide range of power levels

The LD system test bed, for example, offers capability to test systems from 50 kWe to 160 kWe, thus giving you the freedom and choice to use one test bed for a wide variety of power generators.

Expand test cases

Empowered with a powerful test bed automation, AVL PUMA 2™ Fuel Cell, different customized and pre-defined test cases can be incorporated into SOFC system testing, thereby allowing you to expand your test procedures.

Modularity

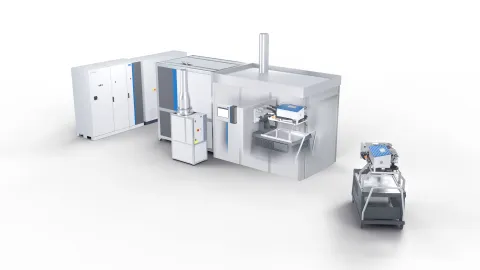

The system test bed is completely modular meaning every piece of test bed hardware can be moved/relocated/arranged as per your individual requirements. Modularity also allows adding more modules in the future if the need arises, thereby making the test bed even more sophisticated and future-proof.

Performance and environmental testing

The basic set of features allows for performance testing of the system on the test bed. With the addition of advanced features, the test bed is also capable of offering environmental testing possibilities. This gives you total control and flexibility on the kinds of test that you wish to perform.

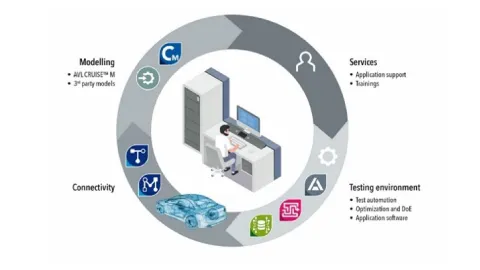

Access to AVL SOFC toolchain

Not only does the test bed come with a set of hardware and software but also with access to the complete AVL SOFC toolchain. The toolchain is key to help you accelerate your R&D efforts with maximum efficiency and productivity.

Global support and service

With presence in 26 countries and 45 affiliates worldwide, you can be assured to receive global service and support when you purchase a test bed from AVL. Moreover, you will benefit from AVL's pioneering activities in the field of fuel cells which will help you soar ahead of the competition.

At AVL, we’re working on this technology for the last 20 years and as the market for this technology matures and ramps up, we are in a very good position to offer highly functional and competitive testing solutions and products to our customers who can in turn bring out innovative systems to meet market needs

– Dr. Vikrant Venkataraman, Development Engineer Hydraulics, AVL