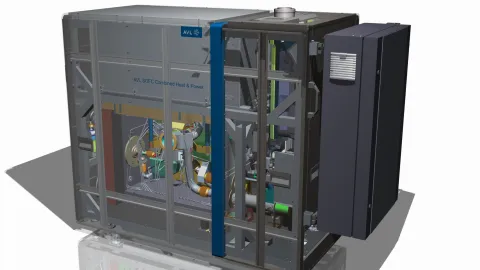

Over the past 20 years, we have gained a great deal of experience in SOFC development and have completed around 100 development projects. The requirements for practical verification, but also the available options for realisation, have constantly evolved and now help our customers to achieve their development goals.

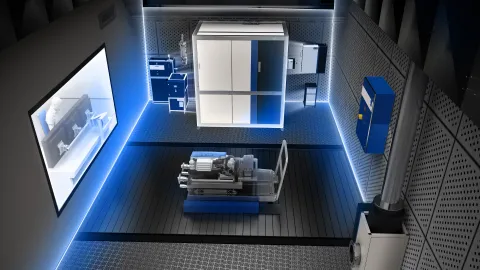

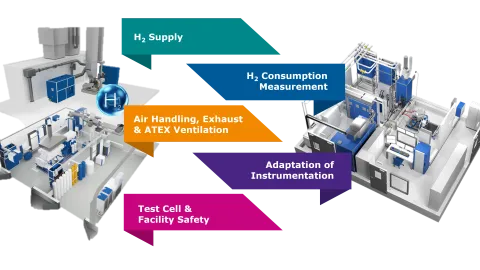

Hardware and software solutions for SOFC test beds

SOFC technology is currently still at the development stage, both in terms of design and the corresponding operating strategy.The main focus of test benches in the development environment is on design validation and proof of performance of the test specimen under specified conditions; in addition, operating strategies for start-up, operation and shutdown are developed, taking into account efficiency and minimising the potential for damage.Our hardware and software solutions in conjunction with established automation provide them with all the necessary framework conditions and the corresponding flexibility.

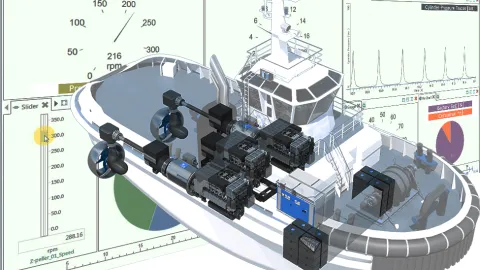

Simulation and emulation

One of the biggest challenges when starting an SOFC development program from scratch is co-simulation and emulation. We overcome these challenges because of our intensive SOFC research.

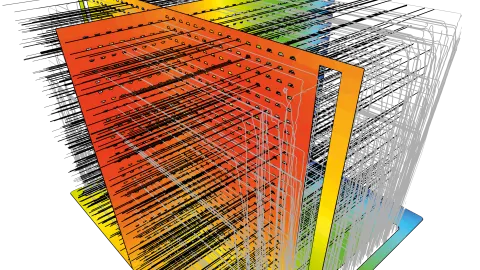

With this background knowledge and our sophisticated simulation toolchain, we first use virtual models and later replace them with actual hardware components. We link these simulation capabilities to our various test benches.

We believe in SOFC technology because it will enable a major leap in efficiency through the intelligent use of resources. This great potential for cost and energy efficiency makes SOFC a technology that has a great future ahead of it.

- Michael Standke, System Line Manager Stationary Fuel Cells, AVL

We support you in the design and development of your own SOFC laboratory. We offer a full range of services, from consulting, engineering, management and procurement of equipment to the construction and successful acceptance of the laboratory.

Our engineering teams work for leading manufacturers and research institutes around the world on the development and testing of fuel cells. We have helped to shape the development methodology for a wide range of performance classes and application areas and have developed a corresponding product and solution portfolio to support them with their individual challenges.