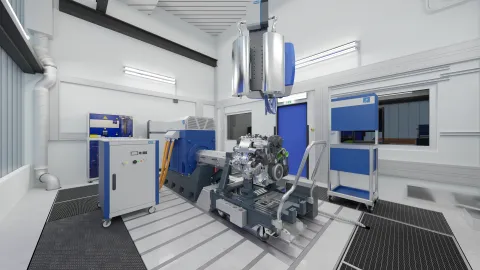

Engine testing has been at the heart of AVL for more than 70 years, creating a legacy of unparalleled expertise in the field. Over the decades, this in-depth knowledge has been demonstrated in the installation and operation of thousands of engine testbeds around the world. From traditional ICE to advanced hybrid systems, AVL has consistently pushed the boundaries of engine testing technology.

Our dedicated powertrain engineering team plays a key role for our success. This global network of experts continuously refines and enhances our test systems to meet the evolving needs of the mobility industry.

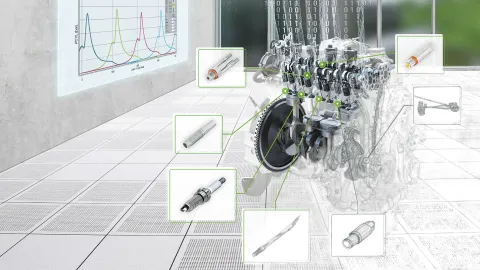

We offer a comprehensive portfolio of engine test systems that address a broad spectrum of research and development challenges in the automotive and mobility sectors. Our solutions are tailored to support the development of both internal combustion engines (ICE) and hybrid propulsion systems, ensuring high precision and reliability across all stages of the development lifecycle. Our test systems are equipped to handle a wide range of complex tasks, including:

-

Hardware Verification

-

System Integration, including Hybrid Components

-

ECU / HCU Calibration

-

Hybrid Operating Strategy Implementation

-

Fuel Consumption Optimization

-

Electric Charge Determinations.

-

Steady-State and Dynamic Duty Tests

-

Engine Response Optimization

-

Exhaust Emissions Development and Homologation

Our advanced engine test systems offer unmatched accuracy and flexibility to solve even the most complex development challenges. With our technology, engineers can accelerate innovation while ensuring optimal performance and regulatory compliance.

At AVL, we are committed to driving innovation in engine and hybrid testing. Our cutting-edge technology empowers our customers to overcome today’s development challenges while preparing them for the future of mobility."

– Michael Messner, Global Business Unit Manager, AVL List GmbH

At AVL, we ensure the efficient use of the testbeds through continuous improvement, driven by our in-house engineering expertise. Our dedicated powertrain engineering and test system development teams work closely together to ensure seamless integration at all stages of development.

Our holistic product portfolio, featuring hybrid and engine test systems, provides a fully integrated solution supporting development from concept to production. By linking development steps with advanced methodology tools, we ensure effective progress throughout the lifecycle.

In addition, our Test Application Support team is available around the world, providing customers with first-hand expertise to solve complex development challenges. Our engineers guide customers through every stage of the development process, providing in-depth knowledge and practical insight.

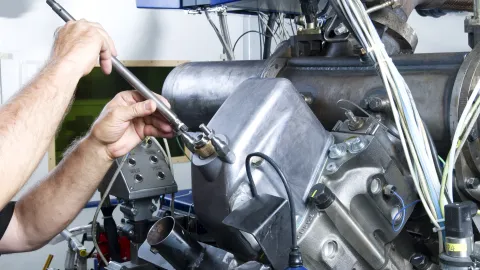

To ensure a right-first-time approach, we utilise our system integration test environments, where complex test system configurations can be thoroughly verified prior to delivery. This approach ensures the highest levels of accuracy and reliability. By combining realistic test conditions with AVL simulation models, we provide accurate, real-world test results to drive successful product development.

AVL Test System Automation – Brochure

Tailored Software Solutions for Future-Proof Test Environments.

The AVL Fuel Mass Flow Meter and AVL Fuel Temperature Control combine high accuracy and excellent temperature stability with short measurement times.

Ensuring the efficient and professional calibration of AVL fuel consumption measurement devices according to ISO 17025.

AVL FuelExact™ takes advantage of the well-established and highly precise measurement principles (PLU or Mass Flow) combined with the world’s best fuel temperature control.

Fuel flow meter for close-to-engine applications and the testing of components, engine, and vehicles.

Fuel consumption measuring system for the heavy-duty and non-road mobile machinery industry.

Visualize the combustion process with our optical measurement equipment integrated into the AVL X-ion data acquisition platform.

The market-leading testbed monitoring and control system for a variety of propulsion systems

High quality sensors offering supreme measurement accuracy. Our portfolio for combustion analysis consists of a large number of pressure sensors for various measurement tasks.

AVL’s comprehensive worldwide network of experts allows best customer vicinity, ensuring consistent and connecting testing fields globally. Wherever your R&D challenges take you, we are always close at hand, ready to provide the service you need.

> 4,000

engine testbed installation projects successfully completed

> 100

hybrid & engine testbeds operated in AVL Tech Centers around the world

> 70

years of test system development experience

> 1,000

test system experts active globally