In the fast-paced automotive industry, rapid technology evolution demands efficient development and quick time-to-market, particularly with electrification. Extensive validation of new features is costly and time-consuming. Harnessing data analytics and AI streamlines this process, reducing costs.

Additionally, AI-driven solutions enhance battery production stability, ensuring consistent quality and reliability. By detecting issues early and optimizing processes, manufacturers improve product quality, reduce warranty claims, and boost customer satisfaction.

Time to Market and Development Efficiency

In the automotive industry, time to market and development efficiency are critical factors due to rapidly evolving technology especially in the field of electrification. The complexity of integrating new features often require extensive validation.

Considering the short time-to-market and the high cost of testing and prototypes, the use of data analytics and AI offers great potential to solve this challenge.

Production Scrap

Challenges surrounding battery production stability and scrap management are considerable. Production stability issues often arise due to variations in raw materials, supply chain and manufacturing processes, leading to inconsistent performance and reliability of batteries. This can result in increased warranty claims, customer dissatisfaction, and potentially costly recalls.

By integrating advanced data analytics and artificial intelligence (AI) algorithms, manufacturers can detect potential issues early, optimize production processes, and improve overall battery reliability.

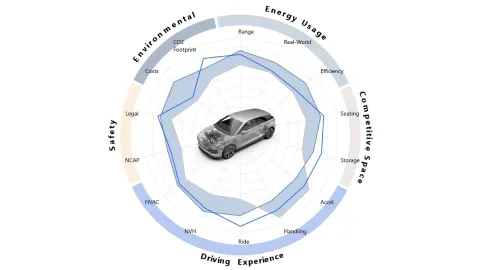

Product Quality

Issues such as driving range, aging, safety, and reliability directly impact end customers and can erode brand trust and lead to huge warranty costs, if not addressed effectively.

Employing AI failure prediction and preventive maintenance actions such as OTA software updates can mitigate these challenges and significantly improve total cost of ownership (TCO) and vehicle uptime.

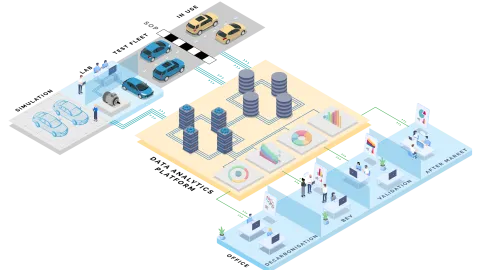

We develop AI solutions based on our extensive domain know-how. These AI methods are delivered during a Proof of Concept and then transferred into the AVL Data Analytics Platform for productive application.

Development Efficiency

Simulation results, lab measurements and vehicle tests are analyzed, classified and predicted on the basis of AI models. These advanced methods are deployed at the customer utilizing AVL’s Data Analytics Platform. Data import, model execution and reporting are automated.

This approach can reduce the test time by 20 %.

Warranty costs

AI models are trained on the basis of the telemetry data, which are then deployed at the customer's premises and integrated into their cloud environment. Each vehicle is given a risk score, which can be used to avoid breakdowns with predictive maintenance.

Quantitative results: up to 93% of recalls can be avoided.

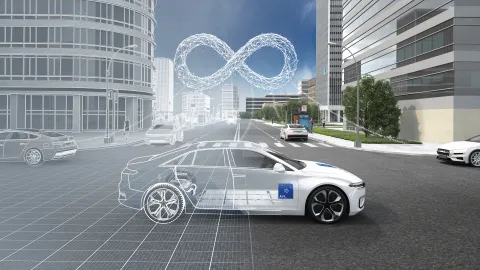

Digitalization and Data Intelligence are boosting efficiency throughout the complete development process. Automated data processing, analysis and reporting enable fast, data-driven decision-making in the engineering process.

Development Efficiency

When working with AVL, together we can achieve a reduction of time-to-market of up to 3 months already in the concept phase. This is a proven result from a customer project using the AVL Vehicle Composer.

In requirements engineering we can achieve a 20% reduction in manpower (testing time) thanks to the use of AVL’s generative AI.

Furthermore, In the validation phase during development, we can reduce the number of prototypes by 10%.

Best of Both Worlds

Thanks to the combination of our long-term experience with vehicle engineering, profound know-how in vehicle integration, SW platform and AI models we achieve significantly beter modelling results and shorter development times.

AVL Data Analytics™

The enabler for productive AI solutions

Data Analytics provides you with a practical framework for all engineering challenges in terms of targeted and professional data analytics in the automotive field. From raw data to data jewels in just a few seconds.

The event-based analytics approach enables interactive exploration and result comparison of time series data no matter if it is produced by simulation, on testbeds or in vehicle fleets. Domain-specific toolboxes support your engineering tasks.

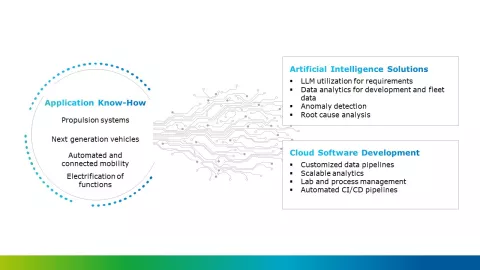

Applied Data Science and AI Solutions

Based on 70 years of AVL engineering know how AVL developed advanced data science solutions for various domain-specific applications. We deliver customized AI methods for:

- Data-driven root cause analysis for a broad range of engineering issues

- Battery health estimation and prognostics

- Early failure detection and failure prediction for large vehicle fleets

- AI-powered digital twin solutions

Digital Services

AVL supports the digitalization of vehicle engineering with automated DevOps pipelines and creates customized cloud software solutions for scalable processing of connected vehicle data. Our experts integrate and deploy these solutions into your infrastructure enabling digital services for end customers.

- Customized and scalable data analytics

- Big Data on AWS, Azure and GCP

- Custom web and mobile applications

- DevOps / MLOps

- Automated SW testing

Solution Sheet: Testing as a Service (TaaS)

DownloadSolution Sheet: Data Management Consulting

DownloadUse Case: Vehicle Fleet Health Monitoring and Prognostics

DownloadUse Case: Electric Vehicle Range Prediction

DownloadUse Case: AI-based Adaptive Controls

DownloadUse Case: Optimal Routing Tool for ADAS Validation

DownloadUse Case: Customized Navigation and Route Optimization

DownloadUse Case: Battery Analytics for Vehicle Fleets

DownloadUse Case: Intelligent Automation Using Machine Learning

DownloadUse Case: End-Of-Line Product Classification

DownloadUse Case: Next Service Forecasting for Connected Vehicles

DownloadUse Case: Robustness Analysis of Diagnostic Functions

DownloadRelated Topics

We are constantly working on new solutions. The following might be interesting for you: