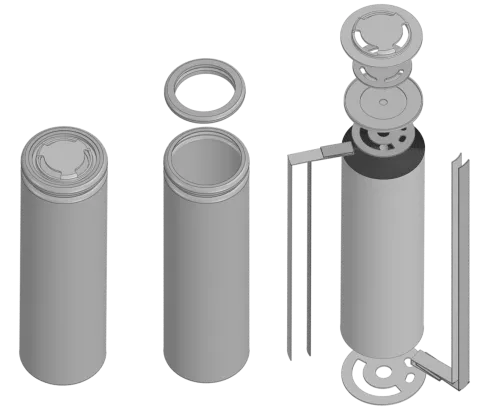

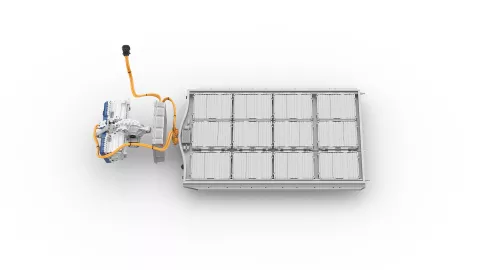

Compared with the rapid advances in the electrochemistry of battery cells, the formats and housing forms have barely changed over the past 20 years. However, this aspect is increasingly coming into focus with the latest new developments. It is crucial for functional integration capacity, and thereby one of the central challenges when it comes to designing innovative cell-to-pack or cell-to-chassis implementations.

Optimized Performance

Increasing energy density while maintaining low costs and high charging capacity.

Function and Lifetime

Improvements to functions and a longer lifetime of cells and electrode stacks through electric, thermal, and mechanic simulations.

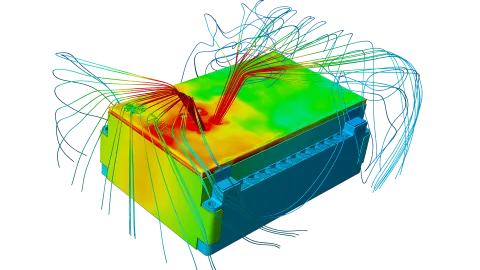

Thermal Safety

New designs that prevent cell runaway, ensure directed ventilation, and monitor break points.

Our development services and our detailed consultancy services are founded on our research and analyses in the area of battery cells:

- CAD modeling: Variety of designs from classic to “tabless”

- System integration: Mechanical and thermal

- Electrochemical and electrothermic analyses

- Degradation analyses: SEI formation, particle crack formation, etc.

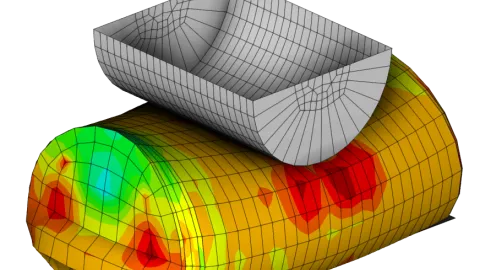

- Mechanical analyses: Swelling and breathing, crash and crush, etc.

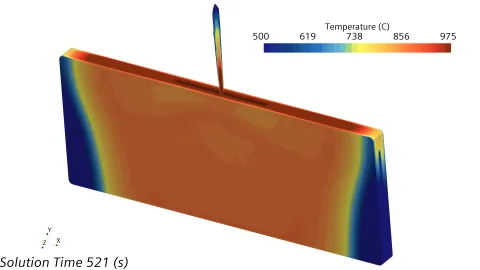

- Thermal runaway analyses: Propagation time, increase in pressure, heat transfer, etc.

Integration with Function

AVL is a leading organization in module development. This background enables us to design tailored cells and cell casings, and target increasing their integration capacity.

Ten Years of Experience with Cell Suppliers

We know the battery cell market and take on the technical management of suppliers. With our validation and quality processes, we support the highest demands in the automobile supply chain.

At the Forefront of Electrode Technology

Silicon anodes, solid state electrolytes, sodium ions – with our broad research expertise, we future-proof your battery project – no matter which electrochemical option you choose.

Parametric Cell Designs

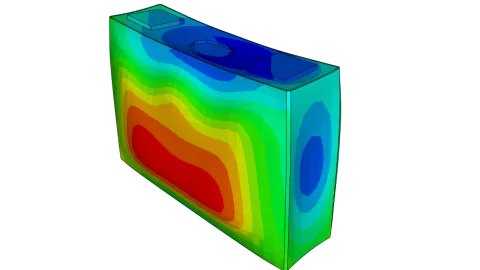

We develop precise CAD models for power and energy cells in any design variant. In line with the defined performance targets at system level, we optimize the CAD drafts with regard to their mechanical and thermal integration capacity and scalability.

Modeling and Analysis

Our electrochemical analysis of battery cells is based on the latest generation of electrochemical models; we also use equivalent circuit models (RC model) for our electrothermic analyses. To model abrasion and aging processes, we developed special degradation models, which can be used to model irreversible lithium plating, among other things.

Cell Simulations

We use sophisticated simulations to assess how the format and housing form impact the performance and lifetime of a battery cell. Using virtual models, we can identify and evaluate differences immediately. Based on this, we develop the appropriate cooling concept, to ensure that the desired performance and lifetime targets are met.

AVL’s parametric cell designs opened up totally new possibilities for us – modular cell-to-chassis integration of the battery. I wasn’t previously aware of the positive effects this solution has on the cost structure and on the internal manufacturing strategy.

– Customer feedback after the project

Related Topics

We are constantly working on new solutions. The following might be interesting for you: