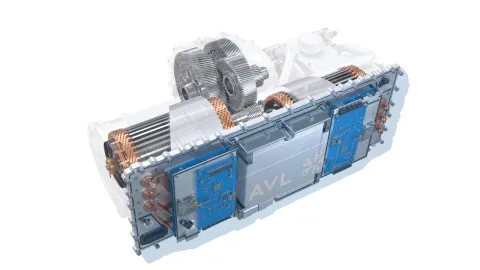

Modern e-axle systems are compact, deliver high power density, and are engineered for maximum efficiency, performance, and drivability. To meet these demands, e-axle test systems must fulfill strict requirements in terms of durability, dynamic performance, and NVH behavior – ensuring not only functional reliability but also a smooth and comfortable driving experience.

Advanced e-axle testing must also address the growing complexity of electric mobility. This includes supporting predictive maintenance strategies, performing in-depth diagnostics, and adapting to changing test requirements. By enabling precise monitoring and fast response to potential issues, e-axle testbeds help minimize downtime and ensure long-term reliability across the entire lifecycle of the integrated e-drive system.

With our in-house engineering expertise, we actively analyze market trends and drive innovation to provide our customers with the best possible support. Based on this deep application know-how, we develop e-axle testing solutions that help our customers achieve their development goals.”

– Reinhard Merl, Global Business Segment Manager, AVL List GmbH

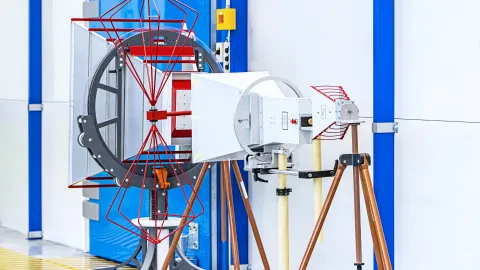

Our pre-engineered e-axle testing solutions are designed to minimize Total Cost of Ownership (TCO) while meeting strict requirements for service lifetime, NVH, and EMC compliance. With a compact footprint and low energy demand, they support efficient use of space and resources.

To maximize operational efficiency, our solutions enable faster test cycles and seamless integration into existing automation environments for fully automated testing. By significantly reducing grid power consumption, they contribute to lower environmental impact and support sustainable, energy-efficient testing operations.

AVL E-Mobility Testing Solutions – Brochure

From battery to full vehicle, from products, to test systems to whole test facilites – learn how we can support your testing needs.

AVL E-Axle Testing Solutions – Brochure

Validating Integrated E-Drive Units with Advanced E-Axle Test Systems.

Automation & Control for E-Axle Testing – Solution Sheet

Highly efficient automation and control for e-axle testbeds.

AVL offers comprehensive software solutions to optimize your e-axle testing performance. Our holistic approach combines lab efficiency through automation and test optimization via virtualization for faster results.

The advanced data analytics solution using AI extracts valuable insights from various sources. Additionally, our solutions are designed to seamlessly integrate with your existing systems, ensuring a smooth transition.

This will help you get your products to market faster while ensuring high-quality performance. Learn more about AVL’s approach and explore our software solutions to optimize your e-axle testing process now.

Our test systems enable efficient and reliable E-Axle Performance Testing across all vehicle classes. Whether for light-duty or heavy-duty applications, our solutions cover performance, thermal, and durability validation. Real-world conditions and flexible configurations ensure fast setup and high test productivity.

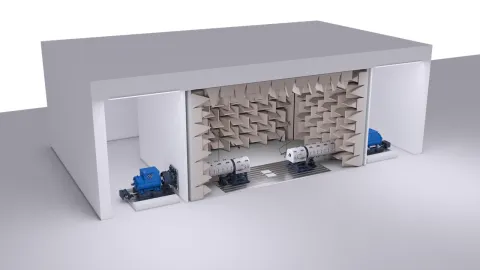

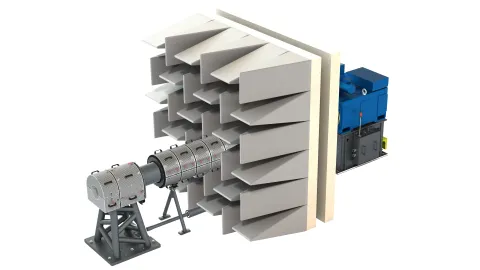

AVL’s deep experience with NVH powertrain testbeds allows to provide a high-quality acoustic test environment for e-axles. All components and acoustic enclosures are designed by AVL to ensure excellent NVH performance with minimal sound reflections through simulation-optimized design.

Based on years of experience in research and development, as well as production, we have developed AVL E-Axle TS™ Production. It provides End of Line (EOL) and Conformity of Production (COP) testing for electric drive applications, from passenger cars to high performance vehicles, as well as industrial applications.

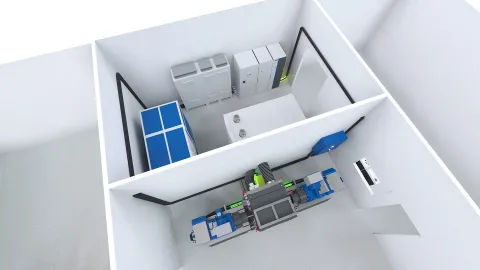

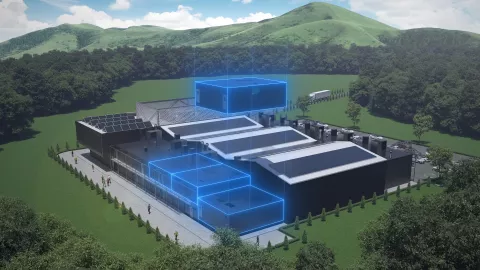

Customer requirements show the need for additional test capacity for ambitious product development plans. AVL Tech Center Modules significantly shorten this process. The flexible, location-independent and easily relocatable modular test system is particularly helpful.

AVL PUMA 2™ is the global industry standard for testbed automation. It is suitable for electrified testbed types as well as for conventional test environments.

Intelligent automation, quick and easy

AVL CAMEO 5™ unlocks a new maturity level of calibration and validation in automotive software testing.

The AVL Customer Services organization consists of more than 700 service- and application engineers worldwide, operating from more than 50 locations. Our global footprint is your local benefit.

AVL’s comprehensive worldwide network of experts allows best customer vicinity, ensuring consistent and connecting testing fields globally. Wherever your R&D challenges take you, we are always close at hand, ready to provide the service you need.

> 30

years of experience.

> 4,000

powertrain experts.

> 500

executed powertrain and e-axle projects.

> 45

global technical and engineering centers.