Commercial vehicle e-axles feature integrated subsystems such as electric motors, inverters, transmissions, and differentials for optimal efficiency and minimum size. Traditional isolated testing of these subsystems is no longer feasible due to their interconnectivity. Therefore, modern e-axle test systems must meet test standards for all electrical and mechanical subsystems, enabling cross-functional testing for performance, reliability, and thermal endurance to save time and money during e-axle life cycle analysis.

AVL's E-Axle TS™ Performance – Heavy-Duty provides comprehensive testing for all subsystems, ensuring efficient performance and reliability analysis with a cost-effective, easy-to-install design.

Minimized TCO

Standardized and pre-engineered solution to be productive in testing as soon as possible.

Increased Efficiency

Testing processes must be efficient to meet development timelines and contain costs while maintaining high-quality standards.

Rising Complexity

Need for a comprehensive test system with a seamlessly integrated automation system.

Standards Compliance

Rigorous testing standards for all electrical and mechanical subsystems must be fulfilled.

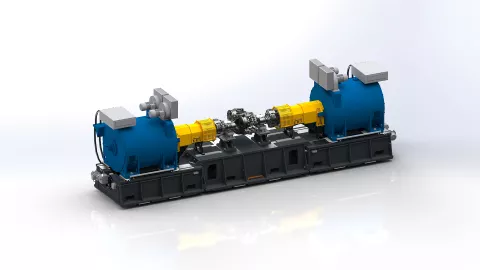

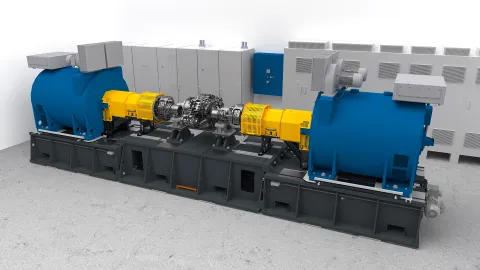

Our e-axle test system is designed for specialized testing under realistic vehicle-like conditions. It features a reliable load system with two compact torque motors, specifically developed for commercial vehicles. These motors meet typical torque, speed, and power requirements while eliminating the need for maintenance-intensive reduction gearboxes.

The system's compact frame minimizes the footprint, making it easy to install on common industrial floors without requiring complex facility modifications. A modular e-axle rigging system ensures simple assembly, while optional climatic chambers enable thermal conditioning for more comprehensive testing.

The technological features described make our test system to a powerful instrument for testing e-axles, streamlining efficient as well as realistic analysis regarding performance, reliability and thermal endurance, consistently ensuring high productivity during all testing tasks.

| Load System | per Wheel |

| Max. Power | 625 kW |

| Max. Speed | 1,250 rpm |

| Max. Torque | 40,000 Nm |

| DC Source | |

| Max. Power | 550 – 1,100 kW |

| DC Output Voltage | 20 – 1,200 V |

| Max. Current | 2,000 A |

| General | |

| E-Axle Types | Rigid e-axles |

| Max. E-Axle Width | 2,600 mm |

| Dimensions (W x D x H) | 8,000 x 1,700 x 2,450 mm |

Ready for Testing

Short delivery time of only

8 months after order (EXW).

Versatile Solution

Designed for common industrial floors without requiring a specific test system foundation.

Small Footprint

Compact test system design of only 8,000 x 1,700 mm.

Reliable Load System

Powerful torque motors without requiring damage-prone reduction gearboxes.

AVL Automation

Our advanced automation software, AVL PUMA 2™, adapts easily to modern testing methods, maintaining consistent and transparent testbed configurations. With streamlined parameter configuration and immediate validation, it minimizes testbed downtime and maximizes output and efficiency.

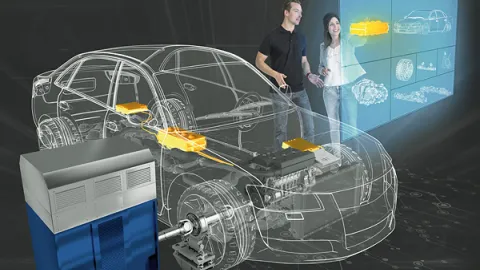

AVL Testbed.CONNECT™

Simulation is the key to effective frontloading. To support our customers in achieving this, we have created Testbed .CONNECT™, a powerful and open execution platform that connects simulation models to the testfield.

E-Axle Climatic Chamber

Components such as e-axles require resilience to diverse environmental conditions, spanning arctic winters to hot tropical summers, with humidity affecting performance and lifespan. Climate chambers facilitate testing to meet standards, including accelerated lifetime tests through thermal shocks.

From customer project insights, we developed a test system unlocking the full potential of e-axle testing. This empowers our customers to efficiently execute their testing strategies, and successfully bring their e-axle developments to life.”

– Christian Wooning, System Line Manager, AVL Deutschland GmbH