In recent years, industries across the board have faced the growing challenge of integrating an increasing number of electrical and electronic (EE) subsystems into their products. To minimize cross-interference between different electrical systems, EMC standards are frequently revised, with industry-specific specifications becoming stricter. As a result, it is essential to incorporate EMC measurement and testing from the earliest stages of development for electrified systems and their components to ensure compliance and optimal system performance.

Throughout our portfolio, AVL EMC testing solutions share the same self-imposed standards:

Performance

Ensuring that test equipment is quickly and safely operational to apply loads and make accurate EMC measurements across the full power range of the unit under test (UUT) is essential for reliable EMC analysis.

Efficiency

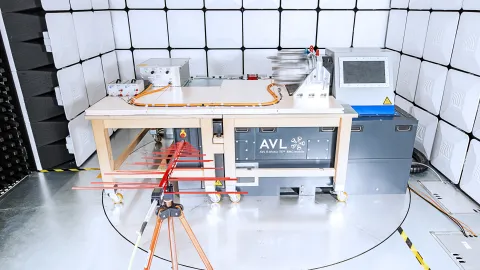

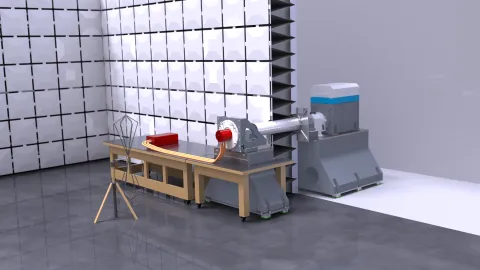

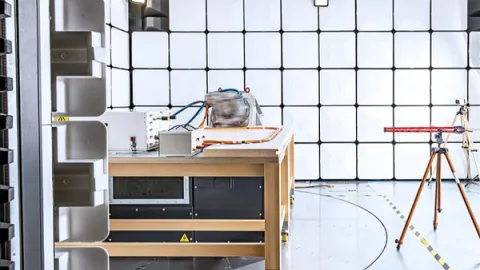

Maximizing testbed efficiency through multi-purpose use of EMC chambers and seamless integration between EMC and load application hardware is a core feature of our test systems.

Rigorous Design Standards

Every component of an EMC testbed is meticulously designed to minimize external interference in UUT measurements. Our test systems are built with rigorous EMC concepts to ensure superior EMC performance without compromise.

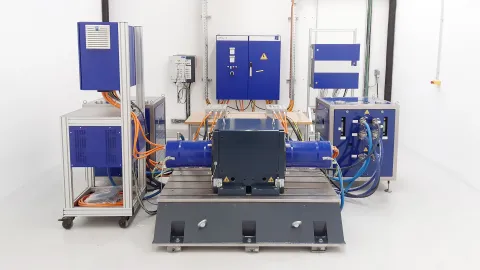

To achieve exceptional loads and speeds in EMC component testing, we leverage our extensive interdisciplinary expertise. Our comprehensive portfolio of standardized load systems allows us to accommodate a diverse range of performance classes. With superior torque and speed control, our systems ensure maximum repeatability of load conditions, closely aligning with EMC criteria. Ultimately, this makes our platform a fully equipped solution for e-motor development.

|

Parameters |

|

|

Radiated emissions |

Frequency range 10 kHz to 18 GHz |

| Ground noise | At least 6 dB (mobile)/10 db (fixed) better than class 5 according to CISPR 25 |

| Immunity field | 400 V/m unmodulated, modulated (80% AM 1 kHz) according to ISO 11452-2 |

The Right Solution for Every Requirement

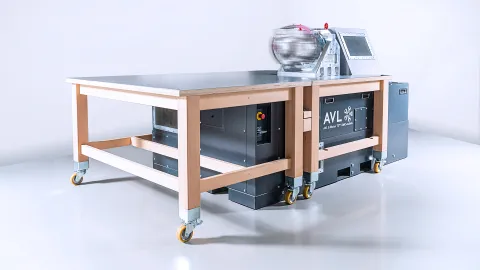

Perfectly tailored EMC testing solutions – ranging from single test components, to mobile and fixed test systems, to a complete turnkey project

A Perfect Fit

A large variety of performance classes that cover speeds up to 20,000 rpm, torque of up to 4500 Nm, and up to 700 kW of power – ensuring the perfect fit for UUTs

Proven EMC Performance

EMC compliance in accordance with the latest standards, including emission and immunity (e.g. CISPR 25, ISO 11452-2)

The AVL E-Motor TS™ EMC provides efficient testing of electric drive systems, ensuring they meet the latest electromagnetic compatibility (EMC) standards. Its advanced capabilities allow for the early detection of potential issues during development, enabling manufacturers to deliver reliable, high-performance electric motors that satisfy market requirements."

– Patrick Hansmann, Lead Engineer EMC, AVL List GmbH

AVL E-Mobility Testing Solutions – Brochure

From battery to full vehicle, from products, to test systems to whole test facilites – learn how we can support your testing needs.

AVL E-Motor Testing Solutions – Brochure

Validate e-motors of different types, speeds, and torques.

AVL EMC Test Systems – Brochure

Control your e-mission.

AVL E-Motor TS™ EMC-mobile – Solution Sheet

AVL E-Motor TS™ EMC-fixed – Solution Sheet

AVL E-Motor Testing Solutions – Application Sheet

An overview of our solutions on 2 pages.