OEMs and suppliers are developing new propulsion system concepts, transitioning from traditional transmission technologies (manual, automatic, dual-clutch) to fully electrified powertrains. Electric drives and high-voltage components are now central to this shift.

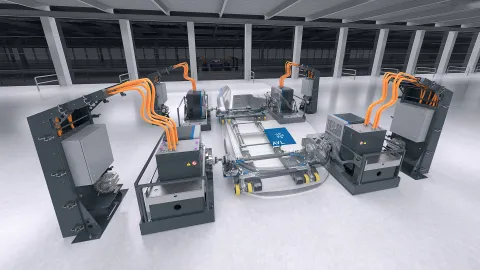

To support development and system integration, customers require testing systems that not only evaluate mechanical subsystems but also optimize high-voltage electrical subsystems. These testing solutions ensure that both mechanical and electrical components are seamlessly integrated, enabling efficient and reliable performance in modern powertrain designs.

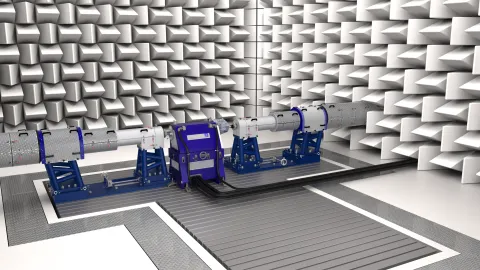

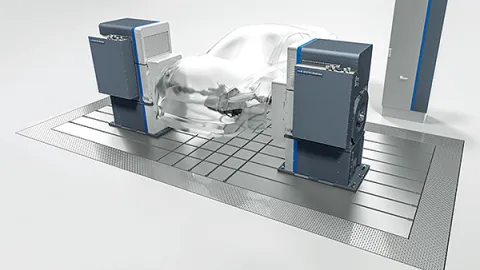

Our modern powertrain test systems are designed to validate all types of propulsion systems, including 2WD, 4WD, and electrified powertrains. They support a wide range of speeds, torques, power classes, and voltage and current levels. The dynamometers simulate real-world driving conditions, road data replication, or time-lapsed testing, providing precise speed and torque control. AVL's optimized hardware and software toolchain significantly accelerates the design and validation process, allowing for early testing in a virtual environment (frontloading).

The AVL PUMA 2™ automation software enhances the system by synchronizing measurements from all devices, ensuring high data quality. This precision, combined with the system’s measurement, control, and simulation capabilities, allows customers to perform real-world driving maneuvers and energy consumption tests without needing a physical vehicle. As a result, propulsion systems can be developed more efficiently, reducing development time and increasing overall project success.

Propulsion system architecture and components have evolved rapidly in recent years, leading to new challenges and opportunities. AVL continues to provide tailored solutions that enable our customers to focus on development with confidence, knowing their measurement results are accurate and reliable."

– Reinhard Merl, Global Business Segment Manager, AVLList

AVL powertrain system testing solutions are built on innovative, proven technologies, from dynamometers supporting various power classes to automation software that adapts to a wide range of applications. Our deep application expertise and system integration capabilities drive efficiency for our customers.

We provide the perfect powertrain testing solution tailored to your specific needs, whether it’s for performance optimization, durability testing, or the integration of complex high-voltage components.

AVL Test System Automation – Brochure

Tailored Software Solutions for Future-Proof Test Environments.

Test time on a testbed is a precious resource that is often wasted on extensive preparation rather than focused testing. We understand the frustration of spending valuable time and resources on setup rather than testing. Our AVL X-Rig™ System provides a solution.

AVL PUMA 2™ is the global industry standard for testbed automation. It is suitable for electrified testbed types as well as for conventional test environments.

Transform your e-mobility analysis with AVL CONCERTO 6™, featuring fast data access, AI-driven technologies, advanced visualizations and calculations, and auto-generated reports for superior performance and precise insights.

The device is AVL’s all-in-one solution for RDE/ISC requirements. It ensures precise and reproducible emission measurements under real driving conditions.

Portable on-board soot and PM measurement device.

The SPECTRA converter system is a modular silicon carbide (SiC) converter able to control wheel dynos at unprecedented levels of control accuracy and dynamics thus helping you to test your powertrain with confidence.

Battery tester and emulator for research and development, testing and validation.

The market-leading testbed monitoring and control system for a variety of propulsion systems

The AVL Customer Services organization consists of more than 700 service- and application engineers worldwide, operating from more than 50 locations. Our global footprint is your local benefit.

AVL’s comprehensive worldwide network of experts allows best customer vicinity, ensuring consistent and connecting testing fields globally. Wherever your R&D challenges take you, we are always close at hand, ready to provide the service you need.

> 70

years of experience

> 5,000

employees worldwide for testing solutions

> 30

countries covered by the global network

> 7,000

testbeds installed worldwide

> 80

turnkey projects