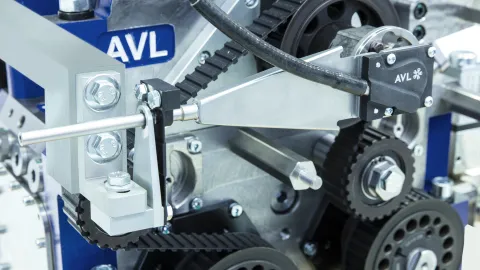

User expectations have significantly increased regarding monitoring equipment on testbeds. The combustion measurement chain is expected for easy set-up to ensure little downtimes and to perform any type of steady-state or dynamic measurements. To accelerate test procedures, new combustion and injection technologies require instrumentation devices delivering highly precise measurements even for efficient engines with low consumption levels during cyclic tests under partial load. In order to comply with internal quality and cost-saving efforts, the equipment is also expected to monitor the health and life cycle of the sensors it reads and to offer high traceability for the data it collects.

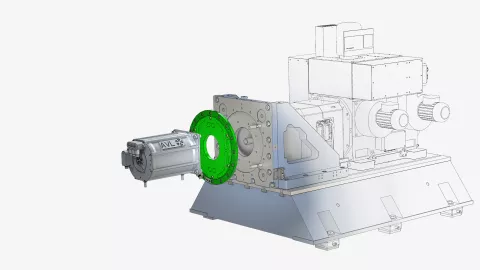

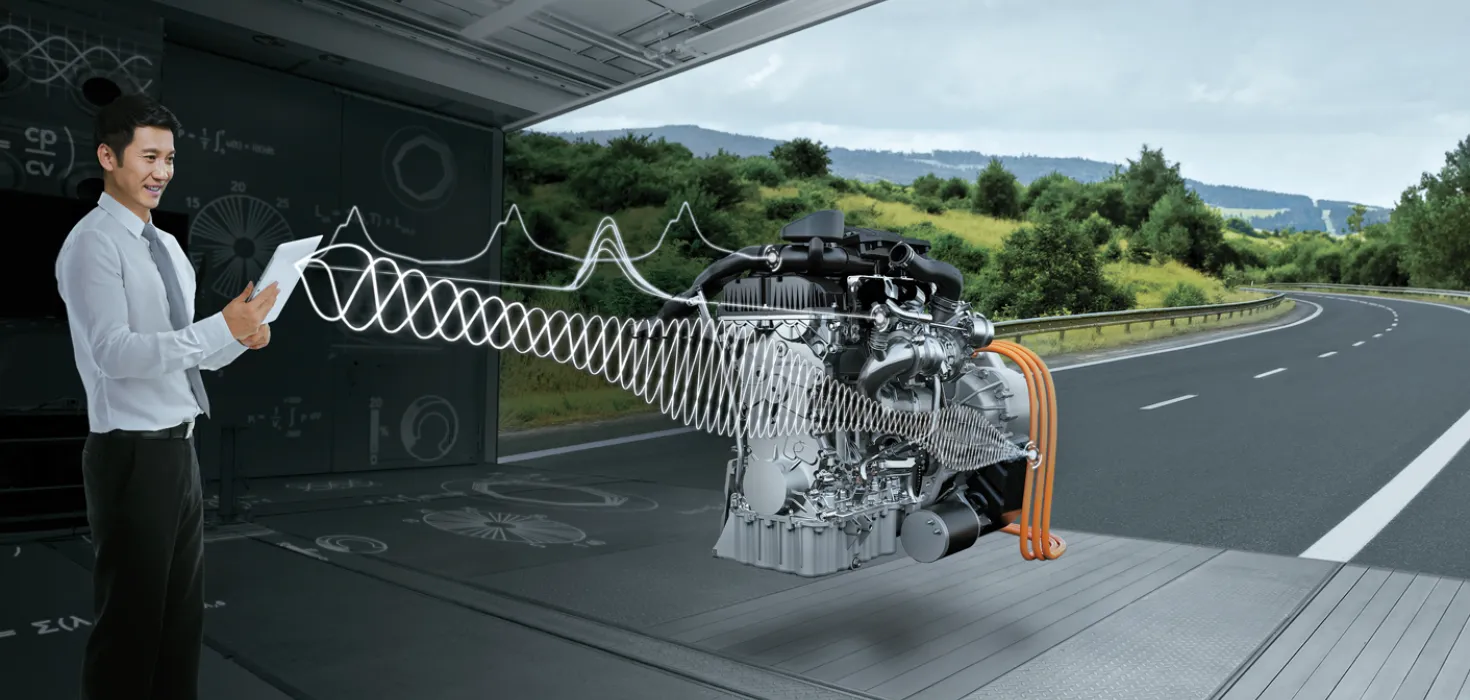

Based on detailed knowledge and experience in the methodology of combustion and e-power analysis, AVL has developed practical tools and devices to make the complex processes of an engine visible and understandable. To support all phases of the development, we offer different solutions for different tasks in development, application and calibration.

AVL has more than 50 years of know-how in the field of consumption measurement technology, technological diversity and clever modular product concepts. This know-how combined with global presence and sophisticated service and system competence have made AVL the world market leader in the field of consumption measurement technology.

We understand our profession as passion to accelerate the transformation to cleaner, more efficient and affordable mobility. Applying decades of know-how in the area of development of propulsion systems in conventional and electrified applications is underlined by industry-leading measurement solutions.

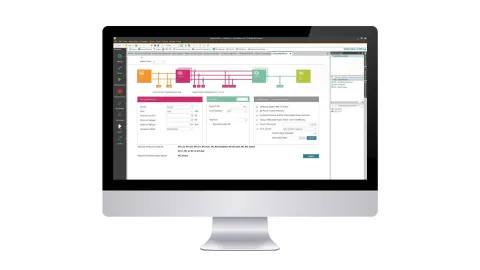

Explore our advanced measurement systems for combustion, consumption and e-power on AVL Experience Cloud. This interactive showroom offers future-proof automotive hardware solutions. Use AVL Experience Cloud to conveniently purchase our products:

- Explore the latest features

- Learn more about our devices and accessories

- Get one-on-one support from international success managers

- And much more

Highlights

Everything that excels at a glance: AVL highlights you shouldn't miss.