E-Mobility Engineering

Electric vehicles are a key enabler of sustainable mobility. We adopt new approaches to shape and simplify the transformation for you. When it comes to developing battery electric and fuel cell electric vehicles, we offer the following:

- All engineering services – from the individual component to the system and integration into the vehicle

- Support with the development of a coordinated overall solution

- Energy efficient technology platforms

- A global network of facilities

Our observations go beyond the vehicle – we also consider the necessary charging infrastructure and primary energy production. At the same time, we make sure to optimize the overall systems– to make electric vehicles affordable. We work with you to find the optimum when it comes to costs and sustainability throughout the lifecycle.

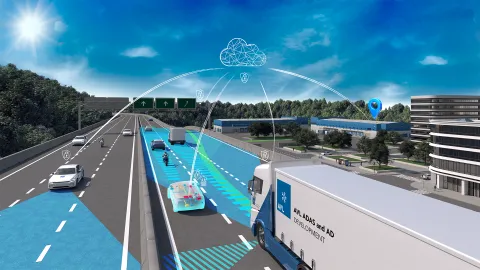

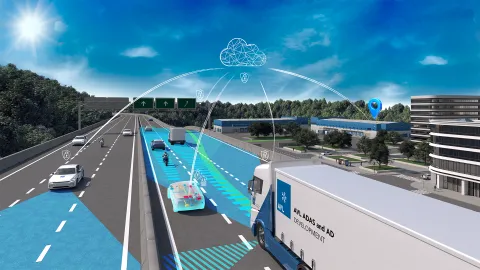

Automated and Connected Mobility Engineering

Advanced Driver Assistance Systems have become an integral part of modern vehicles. Integrating these functions to the full range of vehicle variants with local requirements is complex. And new, innovative approaches for the higher level of automation also need to be made ready for series production.

Advanced Driver Assistance Systems (ADAS) and Autonomous Driving (AD) require constant development and validation of new functions that meet current standards and legislation as well as end customer expectation. They are integrated into vehicles both as safety and comfort functions. We support you in this task with the utmost efficiency, from defining targets to developing the white-box software and validating the functions, including cybersecurity – both virtually, on our proving grounds and also on real roads.

Vehicle Engineering

Our focus is on virtual and functional vehicle development, as well as on integrating systems into the vehicle. This allows us to consider and optimize functions and control systems holistically in the context of vehicle architecture at an early stage. Which is how we boost the maturity of the concept while also reducing the development time and effort required.

Overall, we guide you towards new mobility. Whether passenger car or commercial vehicles – we reconcile your individual requirements with the expectations of end customers. As your partner in vehicle engineering, we create aligned overall vehicle concepts for you while balancing vehicle attributes and the relevant vehicle system.

Hybrid Propulsion Engineering

The aim of hybrid propulsion is to combine an internal combustion engine and an electric engine efficiently, to make best possible use of the advantages of both types of propulsion systems. We develop and optimize your hybrid propulsion system: thanks to our extensive knowledge of the internal combustion engine, e-motor, hybrid drive, and power electronics we can balance low consumption and compliant emissions with optimal driveability.

Specific software and functions, including calibration, deliver the optimum operating strategy. Systems engineering and model-based simulation enable us to reduce your prototype and testing efforts in SOP vehicle derivative projects by up to 30 %.

Level up your Mobility Engineering

With innovative methods and technologies ready for series production, AVL has been driving the development of all types of mobility systems for many years now. Talk to our experts today!

Explore our broad portfolio of engineering services across all industries with a focus on e-mobility, automated and connected mobility, vehicle, hybrid propulsion and energy system engineering.

E-Mobility Engineering

Our network of experts in all key regions enables us to identify the rapidly changing requirements of the markets early on and in detail. Drawing on this knowledge, we support you in analyzing these requirements and work with you to develop the perfect solution for your e-mobility.

We utilize our in-depth knowledge of propulsion systems and components to develop the system you require and integrate it optimally into the vehicle. From hybrid to battery electric and fuel cell electric vehicles.

Automated and Connected Mobility Engineering

Safety and comfort in the vehicle are increasingly important aspects in mobility. To ensure that your vehicle meets the highest standards, statutory requirements and end customer expectations in these areas, we support you in developing Advanced Driver Assistance functions with maximum reliability – and autonomous driving functions to the same standard. Our experience helps us derive the requirements for the ADAS/AD architecture of the future and transfer them to safe and reliable system. Furthermore, our experts keep up to date with international research and market-specific legislation.

We use our proven systems (SE) and model-based systems engineering (MBSE) to master the increasing complexity and to develop innovative, production-ready solutions for you. Our software systems and components facilitate the functionality of ADAS and AD. We apply validation methods, which also include virtual testing methods such as Vehicle-in-the-Loop, to ensure viability. In terms of cyber- security, we offer solutions to protect your vehicle from external attacks.

Next Generation Vehicle Engineering

We use specially developed methods and all available virtual options to reach your vehicle development goals more quickly. For targeted frontloading we opt for simulations and make use of our in-house toolchain, as well as Hardware-in-the-Loop (HiL) and Software-in-the-Loop (SiL) testbeds. This accelerates your development process – and saves you time and money. Our holistic, functional approach is a major factor in swift development. It reconciles all the vehicle system requirements at an early stage, which enables us to bring forward the Start of Production (SOP) significantly.

Hybrid Propulsion Engineering

A hybrid propulsion system uses the best of both worlds, by combining an internal combustion engine (ICE) and an electric engine efficiently, We develop and optimize your hybrid propulsion system: Thanks to our extensive knowledge of the ICE, e-motor, hybrid drive, and power electronics to balance low consumption and compliant emissions with optimal driveability. With specific software and functions, including calibration, we can achieve the optimum operating strategy. Systems engineering and model-based simulation enable us to reduce your prototype and testing efforts in SOP vehicle derivative projects by up to 30 %.

Industrial Energy Engineering

In addition to minimizing pollutants and reducing carbon emissions, the aspect of energy security, meaning the availability of energy sources, is becoming increasingly significant. We address the challenges involved with a wide range of technology and a large regional network.

As a global company, we have an overview of all markets. We know where the emphasis is placed on energy provision in each region, which enables us to offer you customized energy systems.

Our problem-solving expertise for the entire energy supply is the result of both collected data and simulation capabilities.

When developing energy systems, virtual frontloading allows us to map a large number of scenarios very easily. This is how we speed up your development process and keep related costs low.

We offer rapid, competent support around the world. Our subsidiaries, global network of experts, and our extensive expertise give us a global presence – as your reliable partner for ambitious mobility engineering. We have all the relevant topics covered – from e-mobility to ADAS/AD and overall vehicle development.

5,700+

mobility experts worldwide

370+

engineers in the areas of ADAS and AD

480+

engineers for passenger car concept design

450+

fuel cell engineerings globally

120+

engineers for thermal systems and HVAC

900+

battery projects executed

5

Fuel cell tech centers globally

15

ADAS/AD centers of excellence globally

Moving steadily into the future: Find out what’s brand new in the field of mobility engineering.