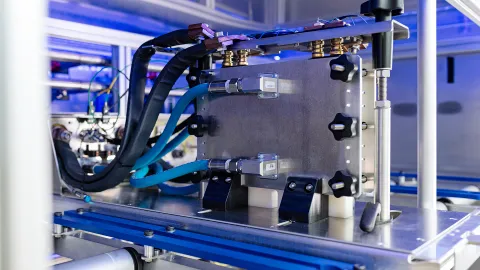

Following this novel approach involves testing various battery cells under highly controlled and stable conditions. As the demand for cells with greater capacity, power, and longevity continues to rise, AVL and the University of Bayreuth have conducted in-depth research to enable more precise life cycle and performance assessments. Essentially, battery cells are surrounded by liquid-cooled conditioning plates (either at the bottom or side). By managing temperature more effectively, direct cooling supports the comprehensive testing required to meet the stringent demands of today’s electric vehicle market.

-

The reference solution enables more efficient cell R&D and conformity of production (COP) testing

-

R&D testing equipment with AVL’s high accuracy cell tester offers high charging and discharging currents for cell validation.

-

The water-cooling approach adds a very accurate, high dynamic temperature control.

|

Temperature range |

-40 °C to +80 °C |

|

Cell conditioning |

via cell conditioning plates |

|

Temperature change (25 °C to 45 °C, battery cell housing) |

85 % time reduction |

|

Control accuracy of fluid temperature |

+/- 0.5 °C |

|

Max. UUT temperature gradient |

up to 25 K/min |

High Thermal Stability

Due to precisely defined conditions, reliable test results and consistency throughout the process is maintained.

Uniform Temperature

The consistent temperature distribution across the entire battery cell surface, creates an optimal environment for accurate evaluations.

Highest Accuracy

Unparalleled measurement precision enables ultra-high precision capacity (UHPC) assessments when combined with the AVL Battery Cell TS™, enhancing performance analysis.

Material Testing

Earlier and relevant test results are facilitated by closely mirroring the conditions of future battery modules and packs.

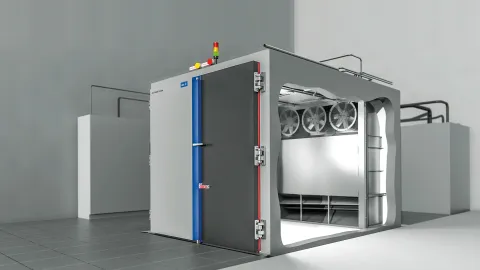

AVL Battery Cell TS™

A battery cell test system is a testbed that includes at least one temperature chamber suitable for testing lithium-ion batteries, a cell cycler in the appropriate current and voltage range, and an automation system. The size of the cell determines which of the various chambers with special safety equipment is required. In addition to the chamber, the cell cycler and the required current and voltage ranges must be aligned with the respective cell.

Lab Management Software Solutions

ACORA offers maximum efficiency in large test laboratories. Our AVL Lab Management Software Solution is the ideal complement. This is used for data and process optimisation to ensure the most efficient use of the test laboratory.

AVL's direct cooling technology enables faster, more accurate, and higher-quality test results for battery cell testing. In particular, the liquid-based cooling application stands out as one of the most innovative approaches.

– Dominik Strasser, System Line Manager, AVL List GmbH