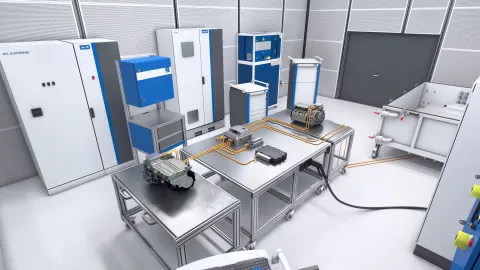

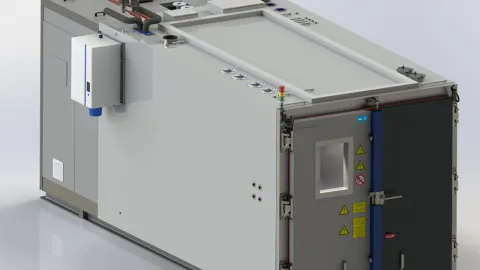

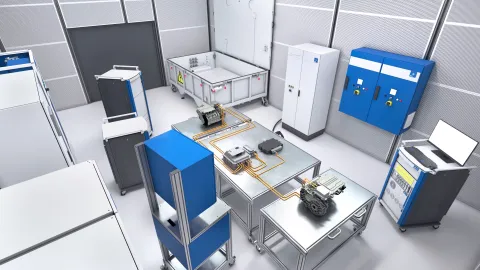

HV systems are complex and dangerous if not properly designed and tested. The AVL HV System testbed provides a safe environment to test HV systems, which helps to prevent accidents and injuries. Besides that, cost-effectiveness is very important. Testing HV systems in a real-world environment can be expensive, time-consuming, and risky. The AVL HV System testbed provides a cost-effective way to test HV systems before they are implemented in vehicles, which can help to reduce development time and costs.

In general, HV systems need to be reliable and robust to ensure the safety of passengers and drivers. The AVL HV System testbed allows engineers to evaluate the reliability of HV systems under different conditions and scenarios, which helps to identify potential problems and improve the overall quality of the system. And also lexibility, as the AVL HV System testbed is highly flexible. With it you can react to the different version pattern phases in hardware development quickly as well as to new software versions during software development. In summary, an AVL HV System testbed is essential for E-Integration tasks as it provides a safe, cost-effective, reliable, and flexible environment for testing and validating high-voltage electric systems.

Reliability

Consistent performance result under a variety of operating conditions.

Safety

Reduce risk for personnel and equipment with a special HV system integration testbed.

Efficiency

Streamline the testing process and reduce the time and effort in testing.

Consistency

Consistent test conditions allow repeatable tests to identify problems with the charging infrastructure.

Cost Savings

Early detection of problems avoids downtime and replacement of costly HV systems.

The specifications of a High Voltage (HV) System E-Integration testbed can vary depending on the specific application and requirements of the test. However, here are some typical specifications that may be considered. It's worth noting that these specifications are just an example and can vary depending on the specific requirements and intended applications of the HV System E-integration testbed. The actual product specifications will depend on various factors, such as the types of electrical components to be tested, the voltage and current ranges, and the specific testing requirements.

|

Improved Reliability and Safety

Testing components and systems in a controlled environment can help identify potential issues and improve their performance, reliability, and safety.

Reduced Development Time and Cost

Reduce development time and costs as issues can be addressed early in the development process.

Simulation of Real-World Scenarios

By simulating e.g. short circuits, overloads, faults, and load fluctuations, test engineers can evaluate the performance of electrical components and systems under various operating conditions to improve their reliability and performance in the field.

Customization and Flexibility

Test engineers can adjust the test parameters, test scenarios, and other testing conditions to test the electrical components and systems under various operating conditions, allowing for greater flexibility in testing.

HV-System Testing

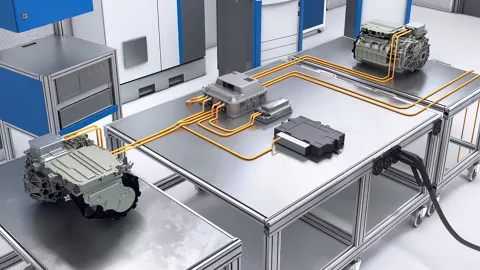

The testbed allows for the individual testing of various HV components such as batteries, electric motors, power electronics, and other related components in their predetermined System.

System Integration

The testbed enables the integration of all HV components and their interaction with other vehicle systems such as the cooling system.

Real-World Simulation

The testbed can simulate real-world scenarios and environmental conditions (e.g., temperature and humidity).

Data Acquisition

The testbed is equipped with various sensors and data acquisition systems that can collect and analyze data related to HV component performance, system efficiency, and energy consumption.

Safety

The HV System E-Integration testbed is designed with safety measures such as protective shields, emergency stop switches, and electrical interlocks to ensure the safety of test personnel and prevent damage to HV components.

Flexibility

The testbed is flexible and can be reconfigured to accommodate different HV system designs and test requirements.

The HV system testbed is a critical tool for the development and validation of high voltage systems. It enables engineers to optimize system performance and safety before deployment in real-world applications.”

– Harald Mahringer, Global Product Manager, AVL List GmbH

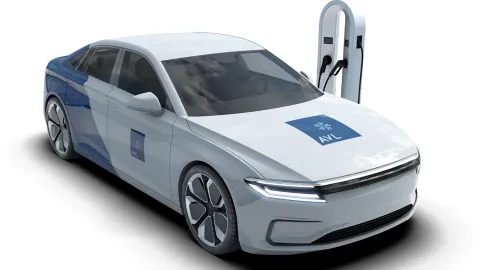

AVL E-Mobility Testing Solutions – Brochure

From battery to full vehicle, from products, to test systems to whole test facilites – learn how we can support your testing needs.

AVL HV System TS™ E-Integration – Solution Sheet

Fast development and validation of electric drives.