Gaseous and liquid media significantly influence the behavior of the UUT. To ensure high precision and reproducibility in testing, conditioning systems are essential as they bring these media into a selectable and predefined range.

Stable environmental conditions are crucial for achieving accurate test results. Conditioning systems provide these stable conditions conveniently and reliably by using conditioned media. This stability is essential for maintaining test precision and reproducibility.

When UUT development occurs in multiple locations, media conditioning systems ensure that testing conditions remain comparable. This consistency is vital for reliable development, calibration, and certification processes.

Accuracy

High control accuracy in steady-state and dynamic mode increases testbed efficiency.

Reproducibility

Good reproducibility allows a fast achievement of development goals.

Conditions

Emulate/ Simulate/ Replicate extreme temperature and pressure conditions on the testbed which is hard to achieve on the road.

Automation

Easy integration into the automation system enables a quick installation (plug & play).

To accurately simulate extreme driving conditions on the testbed, media conditioning systems must create extreme media conditions. This capability is essential for conducting precise and effective tests.

Efficiency on the testbed is significantly enhanced by the timely establishment of initial conditions. Oil and coolant conditioning systems facilitate rapid cooling of the UUT at the conclusion of each test cycle. This rapid cooling process allows for an increased number of tests, such as cold start tests, to be conducted within a given time frame.

Key Features of our media conditioning systems:

- Modular Design: Our systems are designed to be modular, offering exceptional functional expandability to meet diverse testing needs.

- Compact and Mobile: The compactness of our systems ensures high mobility and versatility on the testbed, making them easy to integrate and use.

- Robustness and Durability: Engineered for maximum dynamics and control quality, our systems are exceptionally robust and built to last. With an installed base of over 4,000 systems, their quality and durability are well-proven.

AVL thermal conditioning systems are optimized for dynamic performance and control quality. They enable precise simulations and enhance the overall efficiency of the testbed by allowing more tests to be conducted in less time.

ICE | Transmission | Battery | E-Motor | Power | Fuel Cell | |

| Coolant | ✓ | – | ✓ | ✓ | ✓ | ✓ |

| Boost Air | ✓ | – | – | – | – | ✓ |

| Oil | ✓ | ✓ | ✓ | ✓ | ✓ | – |

| Intake Air | ✓ | – | – | – | – | ✓ |

| Exhaust Back Pressure | ✓ | – | – | – | – | ✓ |

| Altitude Simulation | ✓ | – | – | – | – | ✓ |

AVL ConsysCool Dynamic

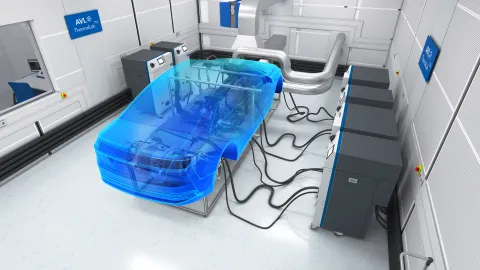

The ConsysCool Dynamic revolutionizes the control of e-drive cooling fluids, ensuring precise adherence to temperature and pressure levels with unmatched accuracy and responsiveness of 6 K/s. It has a capacity of 20 kW to 60 kW and handles temperatures from -25°C to +120°C, providing flexibility for different test conditions. It integrates real-time simulation with hardware-in-the-loop (HIL), effectively simulating refrigerant circuits, e-motors, batteries, etc. This accelerates development by enabling testing of individual components and complete cooling systems, evaluating thermal comfort for parts and passengers under real-world driving conditions on a testbed before moving to more costly wind tunnel or road testing. Therefore, the ConsysCool Dynamic is a key feature of the AVL ThermalLab™.

AVL ConsysActive

Refrigeration units are critical to climatic testing, providing precise cooling for optimal test gradients while maintaining energy efficiency. The AVL ConsysActive products feature efficient compressor control, ensuring that testing conditions are met without excessive energy consumption. Our ConsysActive conditioning units are available with refrigerants with a Global Warming Potential (GWP) of less than 2500, and also in a CO2 version for environmentally friendly options. Air handling modules regulate the air within a walk-in climatic chamber or remote climatic box, ensuring consistent environmental conditions throughout the testing process. These features make ConsysActive an ideal choice for efficient, sustainable and accurate climatic testing solutions.

If standard media conditioning systems do not fully meet your requirements, we offer customized solutions tailored to your specific testing environment. Whether it involves a special design, the use of unique materials, or compliance with custom safety standards, we adapt our systems to fit your needs precisely.

Our customization options cover everything from individual thermoregulators and temperature control units to complete product series. For end-of-line testbeds, we provide customized fill and drain solutions. Additionally, we can integrate customer-specific components from various suppliers, streamlining spare parts management and maintaining optimal productivity.

Adaptation

Adaptations to special building interfaces.

Customization

Customization of temperature, pressure, flow or power range.

Requirements

Tailored to requirements regarding control dynamics and control accuracy.

AVL elevates thermal testing with the AVL ConsysCool Dynamic and AVL Model.Connect. This combination enables hardware-in-the-loop testing of thermal systems, accelerating development from road testing to a controlled laboratory environment."

– Andreas Baumgartner, Global Product Manager Conditioning Systems, AVL List GmbH

AVL E-Mobility Testing Solutions – Brochure

From battery to full vehicle, from products, to test systems to whole test facilites – learn how we can support your testing needs.

AVL Thermal Testing Solutions – Brochure

Keep Cool, Drive Further.

AVL Conditioning Systems – Brochure

Simulate real and extreme conditions with best reproducibility.

AVL ConsysActive Portfolio – Solution Sheet

Precision Climate Control for Versatile and Sustainable Testing.

AVL ConsysCool Dynamic – Solution Sheet

Patented High Dynamic and Precision for HiL Thermal Testing.

AVL ConsysCool – Solution Sheet

Versatile Cooling Solutions for Optimal Performance.